Automated terminal AGV operation site maintenance device and system

A technology of automated docks and maintenance devices, applied in the field of automated docks, can solve problems such as potential safety hazards and the existence of maintenance methods at AGV work sites, and achieve the effect of ensuring safety and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

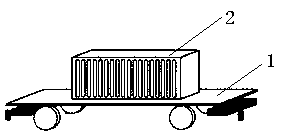

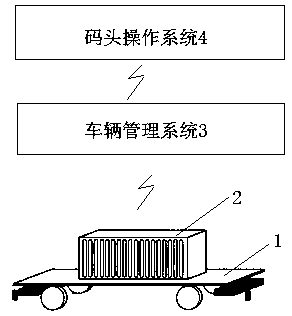

[0021] The automatic terminal AGV operation site maintenance device proposed in this application, such as figure 1 As shown, it includes AGV1 and maintenance room 2; AGV 1 is used to carry the maintenance room 2 to the maintenance area according to the set route, so that the maintenance room can perform maintenance tasks in the maintenance area, wherein the maintenance area and the lock designated for the AGV Closed areas overlap.

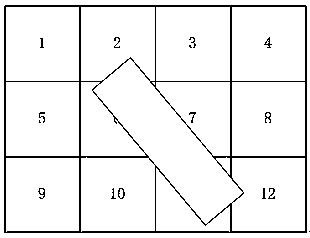

[0022] The AGV's work site can be divided into many regular small grids, and magnetic nails are laid in it. When the AGV trolley is driving, because the AGV itself is relatively large, it will occupy several grid points, so as image 3 As shown, when controlling the operation of the AGV, the method of application, occupation, and release is used to describe its driving process. Generally s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com