screen and method of making it

A production method and screen technology, applied in instruments, projection devices, optics, etc., can solve the problems of interference, overlap of reflection and light absorption parts, divergence of paint particles, etc., and achieve good firmness, uniform picture, and good diffuse reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, specific embodiments according to the present invention will be described in detail with reference to the accompanying drawings. It is emphasized that all dimensions in the drawings are schematic only and not necessarily true to scale, and therefore are not limiting. For example, it should be understood that the dimensions, proportions and angles of components such as the reflective layer, the light absorbing layer and the substrate in the drawings are not shown in accordance with the actual dimensions and proportions, and are only for the convenience of the drawings, but are not intended to limit the present invention. The specific scope of the invention.

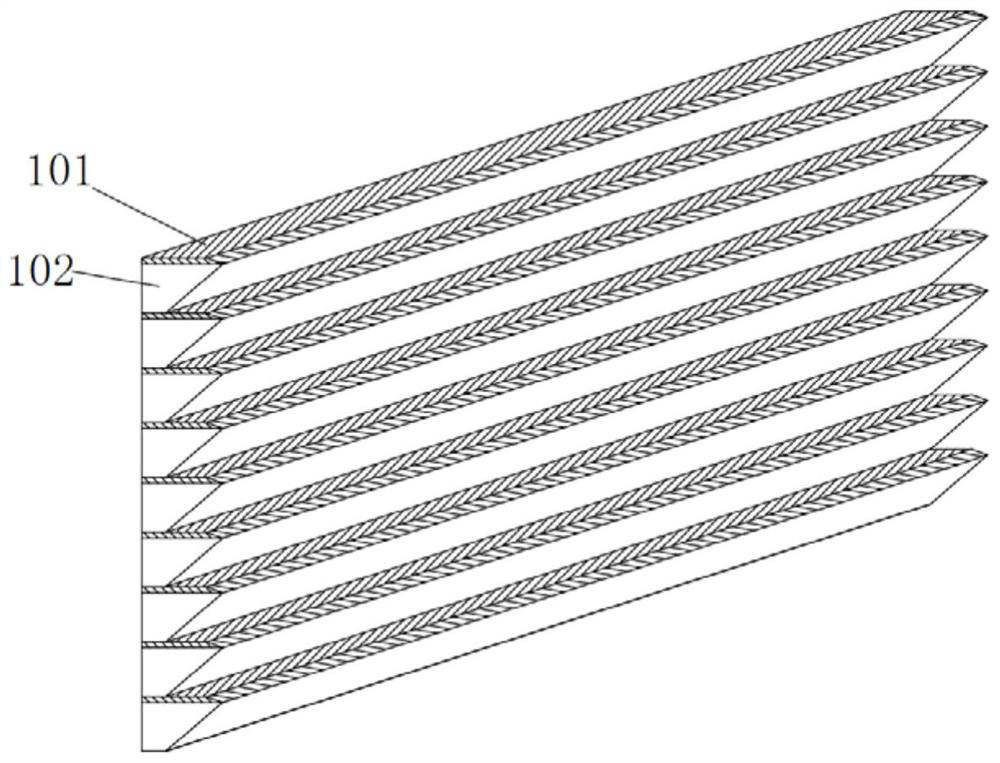

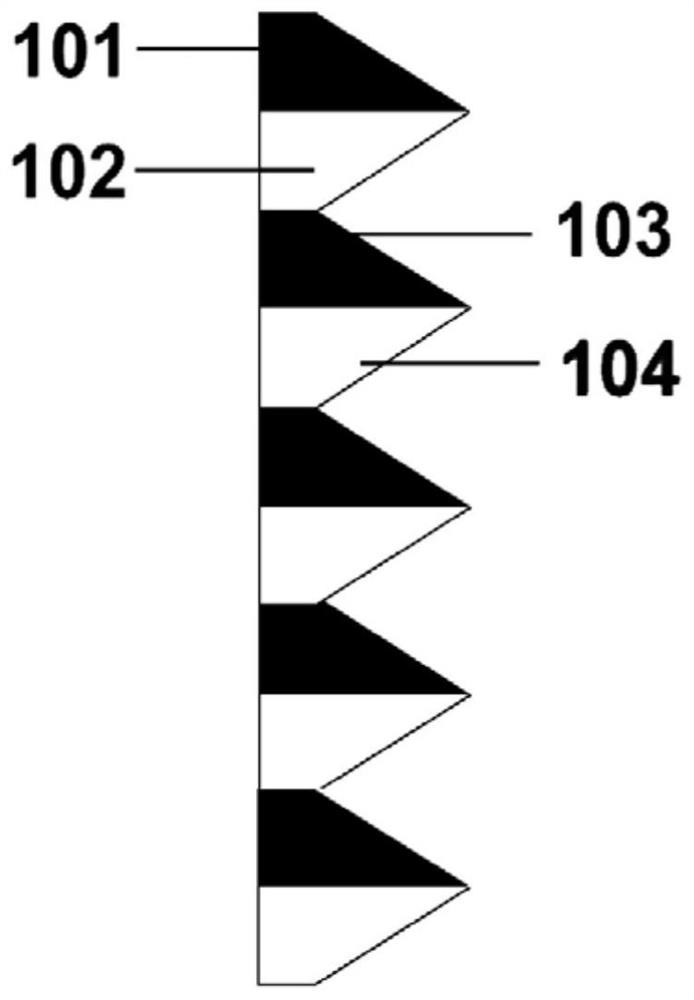

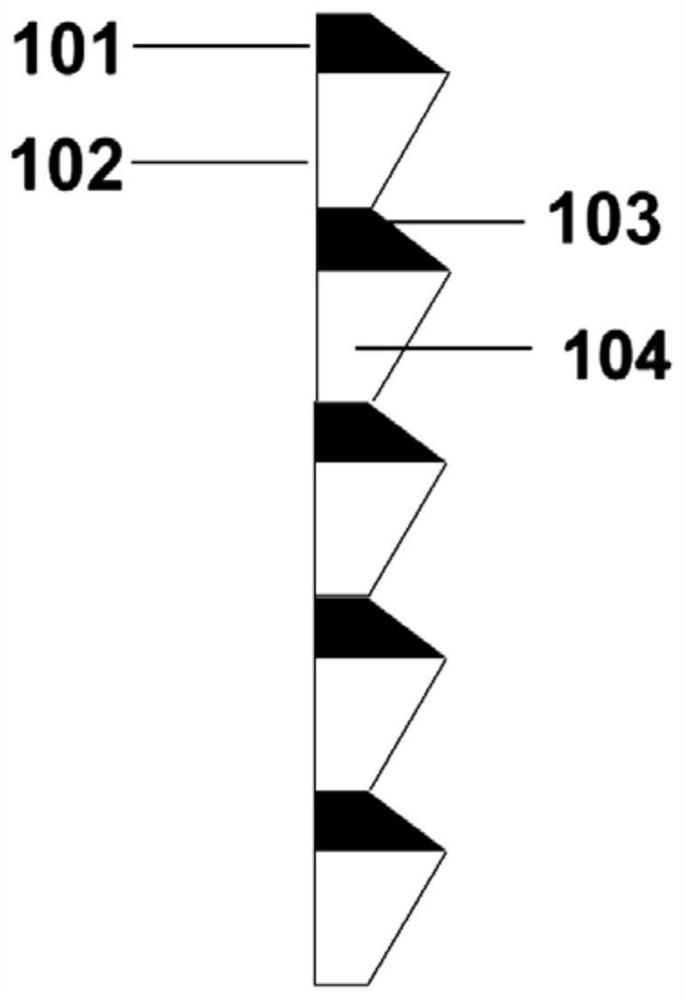

[0032] like figure 1 As shown, the screen 100 of the present invention includes a plurality of light absorbing layers 101 for absorbing ambient light and a plurality of reflective layers 102 for reflecting projected light. Layer 102 as a unit forms a prismatic structure that is stacked to form a jagge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com