Method for determining steam turbine small enthalpy drop blade size considering pre-twisting quantity

A determination method and steam turbine technology, applied to blade support components, mechanical equipment, engine components, etc., can solve problems such as unsafe operation, unreasonable calculation, and affecting steam turbine efficiency, so as to improve safety, improve operation safety, and improve efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

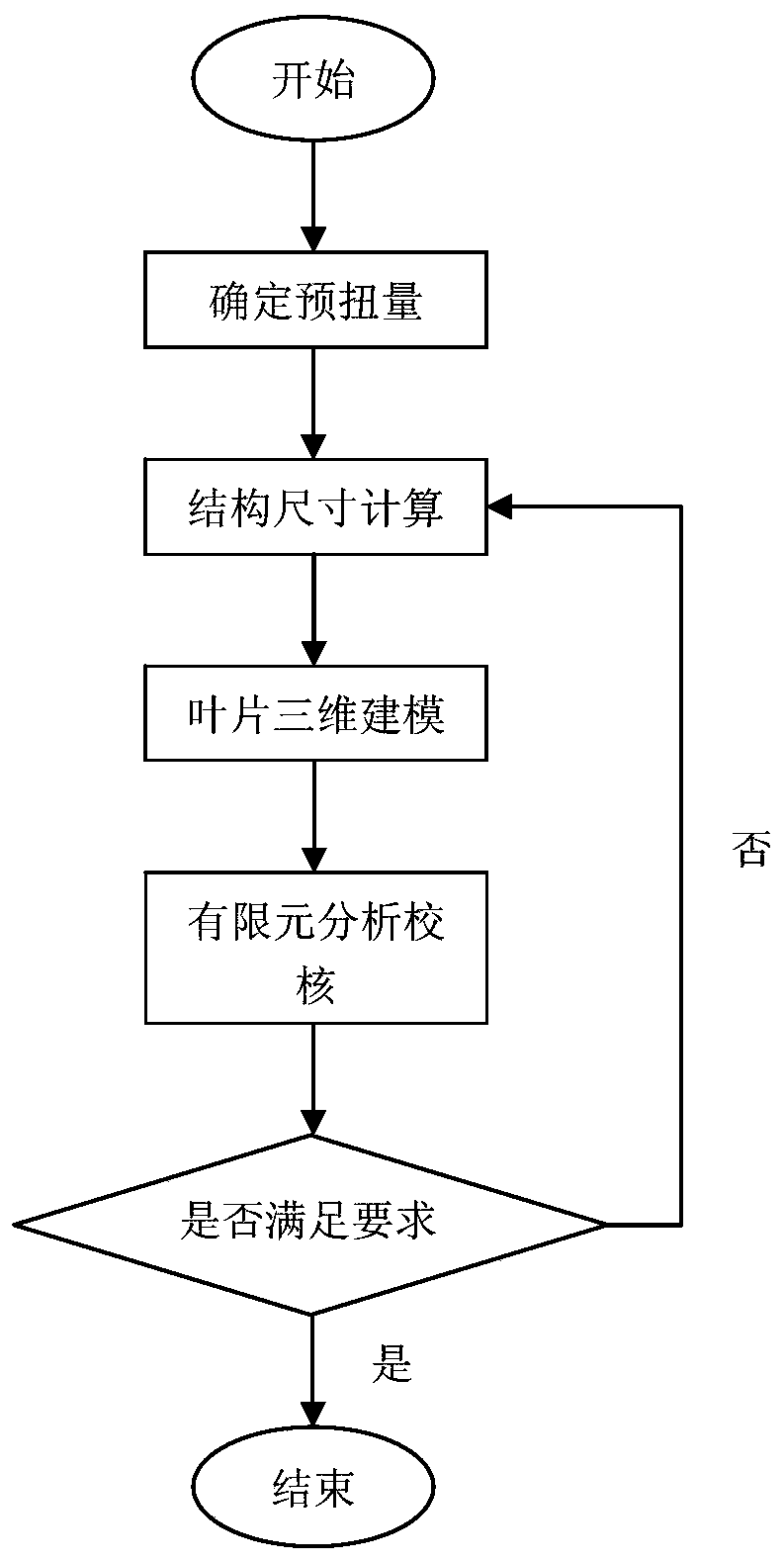

[0020] Specific implementation mode one: combine figure 1 To illustrate this embodiment, this embodiment provides a method for determining the size of a small enthalpy drop blade of a steam turbine considering the pre-twist amount, which specifically includes the following steps:

[0021] Step 1. Determine the pre-twisting amount of the small enthalpy drop blade: Based on the heat and structure of the through-flow, verify whether the blade material can meet the requirements of the pre-twisting design through calculation, and calculate the assembly through mechanical principles when the material meets the requirements. The allowable pre-twist value in the state;

[0022] Step 2. Calculation of the structural size of the small enthalpy drop blade combined with the pre-twist value: according to the obtained pre-twist value, the shroud twist angle in the assembled state is obtained; The key dimensions of twisted blades include blade root pitch, shroud pitch, blade root radial ang...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiments 1 or 2 is that the method for determining the size of the steam turbine blade with small enthalpy drop considering the pre-twisting amount also includes the following steps:

[0024] Step 3. Perform 3D modeling of the blade: Based on the key dimensions obtained in step 2, use UG software to perform 3D solid modeling of the blade, and initially check the rationality of the design of the blade structure size;

[0025] Step 4, carry out finite element analysis checking: apply ANSA software (general computer-aided engineering CAE pre-processing software) to convert the three-dimensional model into a mesh model, export the inp file of the network model, and import it into ABAQUS software (limited engineering simulation element software); then set material parameters, boundary conditions, etc. in ABAQUS software, and perform finite element calculation and analysis; if the result of the calcu...

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 2 As shown, the difference between this embodiment and the first embodiment is that the first step specifically includes the following process:

[0028] During the operation of the pre-twisted blade, due to the temperature change, the linear expansion coefficient difference of the blade rotor, centrifugal force and other factors, the shroud will have a certain twist, so the pre-twisted value will change accordingly.

[0029] The pre-twist design is carried out around the pre-twist value, image 3 That is, the change of the pre-twist value of the blade during operation.

[0030] We divide the time into multiple segments according to the change of the pre-twist value. For the moving blades in the high temperature zone, several important time points are:

[0031] A0: assembly state;

[0032] A1: When the pre-twist value reaches the maximum value during the first start-up process;

[0033] A2: When the unit reaches a steady...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com