Flushing system and flushing method for blast furnace soft water pipeline

A flushing system and soft water technology, applied in the direction of cooling devices, etc., can solve the problem that cooling wall branch pipes cannot be flushed at the same time, and achieve the effects of good flushing quality, improved flushing efficiency, and fast flushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

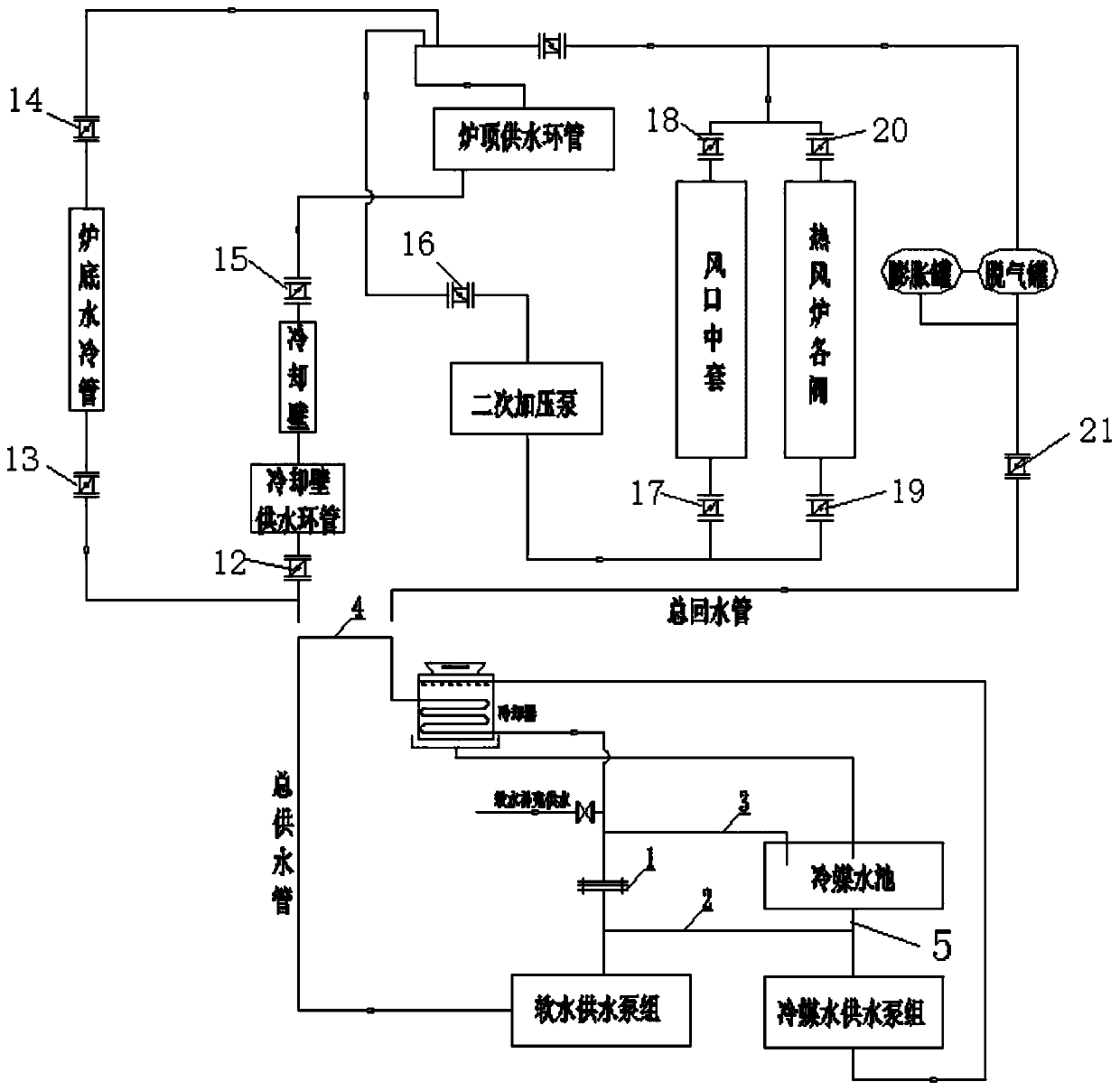

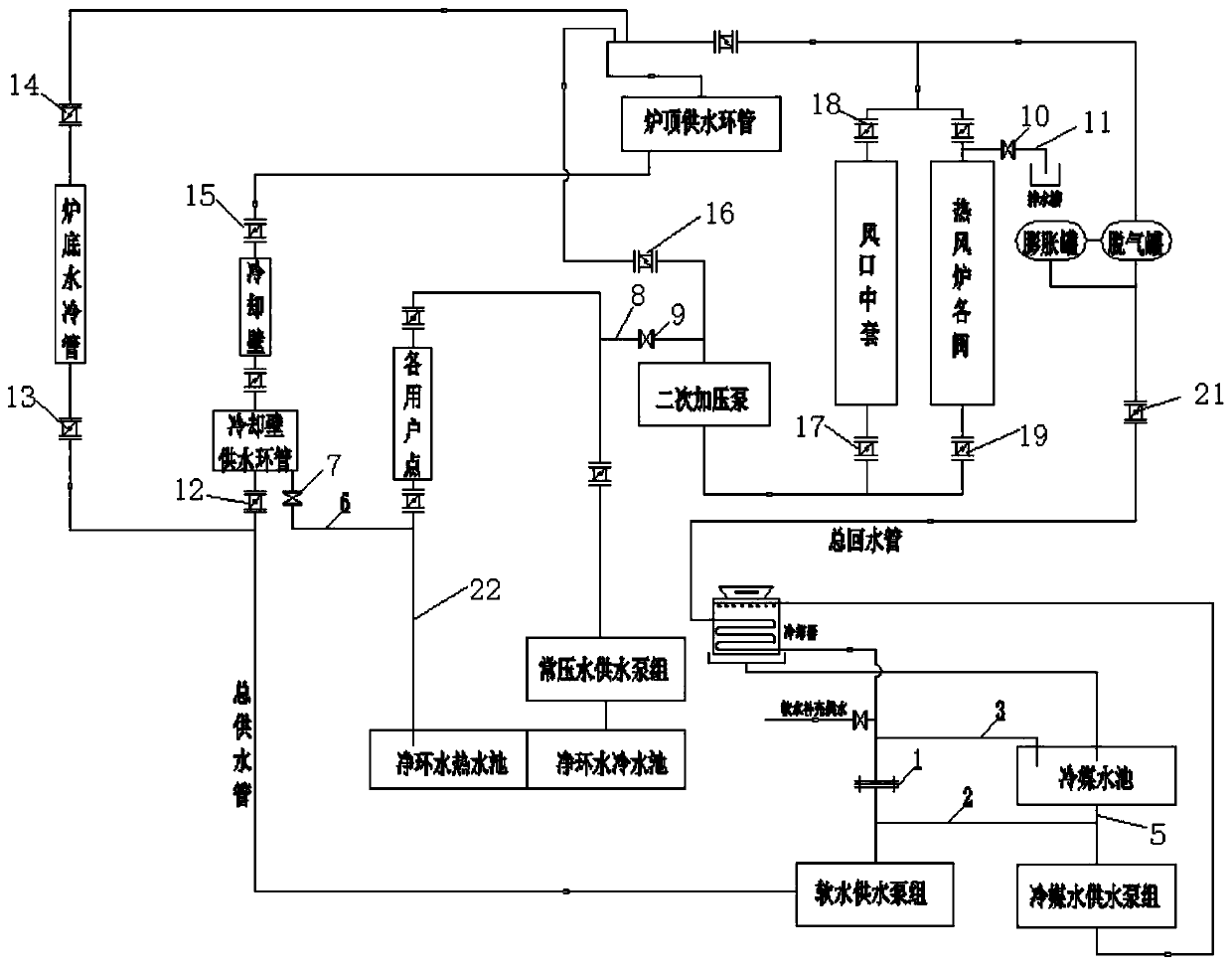

[0030] Such as figure 1 , figure 2 As shown, a blast furnace soft water pipeline flushing system includes soft water supply pumps, hot blast furnace valves, secondary pressure pumps, cooling walls, refrigerant pools, main water supply pipes, main return water pipes and several valves.

[0031] Such as figure 1 As shown, the soft water main water supply pipe and the main return water pipe are respectively disconnected, and a connecting pipe 4 is added at the bottom of the blast furnace to connect the main water supply pipe and the main return water pipe; a blind plate 1 is added between the soft water main return water pipe and the soft water supply pump group A water supply pipe 2 is added at the end of the soft water supply pump group, and the water supply pipe 2 is connected to the outlet pipe 5 of the refrigerant pool and then communicated with the refrigerant pool, so that the soft water main water supply pipe and the main return water pipe are connected at the bottom of...

Embodiment 2

[0051] Using the flushing system and flushing method of blast furnace soft water pipeline in implementation 1, this method is used in Changjiang Iron and Steel 1080m 3 Blast furnace, Masteel No. 2 Iron and Steel General Plant 2500m 3 Blast furnace, 3200m 3 Used in blast furnace construction, the flushing was completed within a week, and the flushing quality met the specification requirements through pipe cutting inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com