A kind of water-soluble rubber and preparation method thereof

A water-soluble rubber and rubber technology, applied in the field of water-soluble rubber and its preparation, can solve problems such as the insoluble solubility of rubber, achieve high economic value and social value, reduce engineering costs, and have the effects of good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

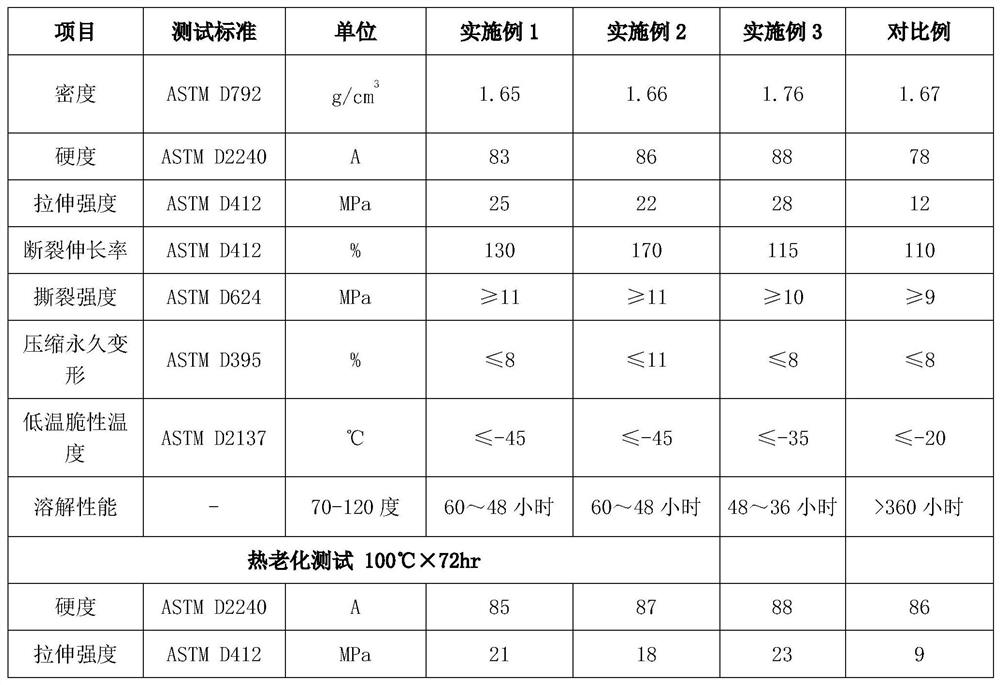

Examples

Embodiment 1

[0031] 1. This embodiment provides a water-soluble rubber, which is mainly prepared from the following components in parts by mass:

[0032] Acrylamide modified polyurethane 55 parts, carboxymethyl chitosan 25 parts, polyvinyl alcohol grafted glycidyl methacrylate 15 parts, maleic anhydride grafted SBS 5 parts, coupling agent 0.5 parts, antioxidant 0.5 parts parts, softener 2.5 parts, crosslinking agent 0.5 parts, accelerator 0.5 parts, sulfur 0.8 parts.

[0033] 2, the present embodiment provides a kind of preparation method of water-soluble rubber, concrete steps are as follows:

[0034] Step 1: Add 55 parts of acrylamide modified polyurethane, 25 parts of carboxymethyl chitosan, 15 parts of polyvinyl alcohol grafted glycidyl methacrylate, maleic anhydride grafted 5 parts of SBS, 0.5 parts of coupling agent, 0.5 parts of antioxidant, and 2.5 parts of softener were mixed at a blending temperature of 210°C for 30 minutes and left for 30 hours to obtain material 1;

[0035] S...

Embodiment 2

[0038]1. This embodiment provides a water-soluble rubber, which is mainly prepared from the following components in parts by mass:

[0039] Acrylamide modified polyurethane 55 parts, carboxymethyl chitosan 25 parts, polyvinyl alcohol grafted glycidyl methacrylate 5 parts, maleic anhydride grafted SBS 5 parts, coupling agent 0.5 parts, antioxidant 0.5 parts parts, softener 2.5 parts, crosslinking agent 0.5 parts, accelerator 0.5 parts, sulfur 0.8 parts.

[0040] 2, the present embodiment also provides the preparation method of above-mentioned water-soluble rubber, concrete steps are as follows:

[0041] Step 1: Add 55 parts of acrylamide modified polyurethane, 25 parts of carboxymethyl chitosan, 5 parts of polyvinyl alcohol grafted glycidyl methacrylate, maleic anhydride grafted 5 parts of SBS, 0.5 parts of coupling agent, 0.5 parts of antioxidant, and 2.5 parts of softener were mixed at a blending temperature of 210°C for 30 minutes and left for 30 hours to obtain material 1;...

Embodiment 3

[0045] 1. This embodiment provides a water-soluble rubber, which is mainly prepared from the following components in parts by mass:

[0046] Acrylamide modified polyurethane 35 parts, carboxymethyl chitosan 30 parts, polyvinyl alcohol grafted glycidyl methacrylate 20 parts, maleic anhydride grafted 10 parts, coupling agent 0.8 parts, antioxidant 0.6 parts , 2.5 parts of softener, 0.5 parts of crosslinking agent, 0.5 parts of accelerator, and 0.8 parts of sulfur.

[0047] 2, the present embodiment provides the preparation method of above-mentioned water-soluble rubber, concrete steps are as follows:

[0048] Step 1, in the internal mixer or open mill, add 35 parts of acrylamide modified polyurethane, 30 parts of carboxymethyl chitosan, 20 parts of polyvinyl alcohol grafted glycidyl methacrylate, maleic anhydride grafted 10 parts of SBS, 0.8 parts of coupling agent, 0.6 parts of antioxidant, 2.5 parts of softener, at a blending temperature of 210°C, knead for 30 minutes, and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com