Soil conditioner for abandoned sand pit and preparation method of soil conditioner

A soil conditioner and sand pit technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as accumulation of heavy metals in soil and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

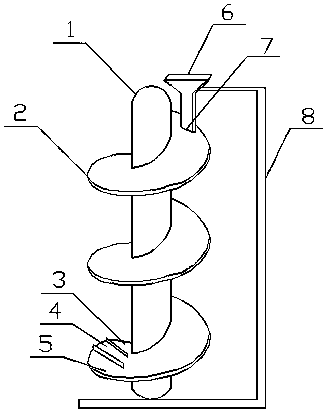

Image

Examples

preparation example Construction

[0027] A soil conditioner for an abandoned sand pit and a preparation method thereof, the specific embodiment of which is as follows: raw materials in parts by weight: 22-40 parts of peanut shells, 0.8-2.3 parts of fermentation bacteria, 9-13 parts of calcium hydroxide, 1-3 parts of sodium chloride, 12-25 parts of high calcium additive, 2-5 parts of binder;

[0028] The peanut shells are decomposed peanut shells, and the method of decomposing the peanut shells is as follows: weigh the peanut shells and fermentation bacteria according to weight, crush the peanut shells and place them on a plastic sieve plate, mix them with soil evenly, and mix the fermentation bacteria and fermentation bacteria Deionized water at a temperature of 28-32°C is stirred with a constant temperature stirrer until it is completely dissolved, put into a watering can and sprayed on the mixture of peanut shells and soil. After spraying, cover the upper layer with 2-3 layers of plastic with a thickness of 2...

Embodiment 1

[0042]A soil conditioner for an abandoned sand pit and a preparation method thereof, the specific embodiment of which is: comprising the following raw materials in parts by weight: 22 parts of peanut shells, 0.8 parts of fermentation bacteria, 9 parts of calcium hydroxide, 1 part of sodium chloride and 12 parts of high-calcium additives and 2 parts of binder. The specific preparation method steps are as follows: Weigh peanut shells and EM bacteria according to weight, crush peanut shells and place them on a plastic sieve plate, mix them with soil evenly, and ferment bacteria and EM bacteria. Deionized water at a temperature of 28°C is stirred with a constant temperature stirrer until it is completely dissolved, put into a watering can and sprayed on the mixture of peanut shells and soil, after spraying, cover the upper layer with 2 layers of plastic film with a thickness of 2mm and accumulate in the sun For 6 months, the decay temperature is 28°C, and it is thoroughly turned ev...

Embodiment 2

[0045] A soil conditioner for an abandoned sand pit and a preparation method thereof, the specific embodiment of which is: comprising the following raw materials in parts by weight: 31 parts of peanut shells, 1.5 parts of fermentation bacteria, 11 parts of calcium hydroxide, 2 parts of sodium chloride and 19 parts of high-calcium additives and 4 parts of binder. The specific preparation method steps are as follows: Weigh peanut shells and EM bacteria according to weight, crush the peanut shells and place them on a plastic sieve plate, mix them with soil evenly, and mix the fermentation bacteria and EM bacteria. Deionized water at a temperature of 30°C is stirred with a constant temperature stirrer until it is completely dissolved, put into a watering can and sprayed on the mixture of peanut shells and soil, after spraying, cover the upper layer with 3 layers of plastic film with a thickness of 4mm and accumulate in the sun For 7 months, the decay temperature is 30°C, and it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com