Uneasy-to-block vertical type solid-liquid separator for kitchen and fruit and vegetable garbage

A technology for solid-liquid separation of fruit and vegetable waste, applied to presses, manufacturing tools, etc., can solve the problems of dead angles in separation, high operating costs, and high costs, and achieve the effects of thorough solid-liquid separation, reduced operating costs, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

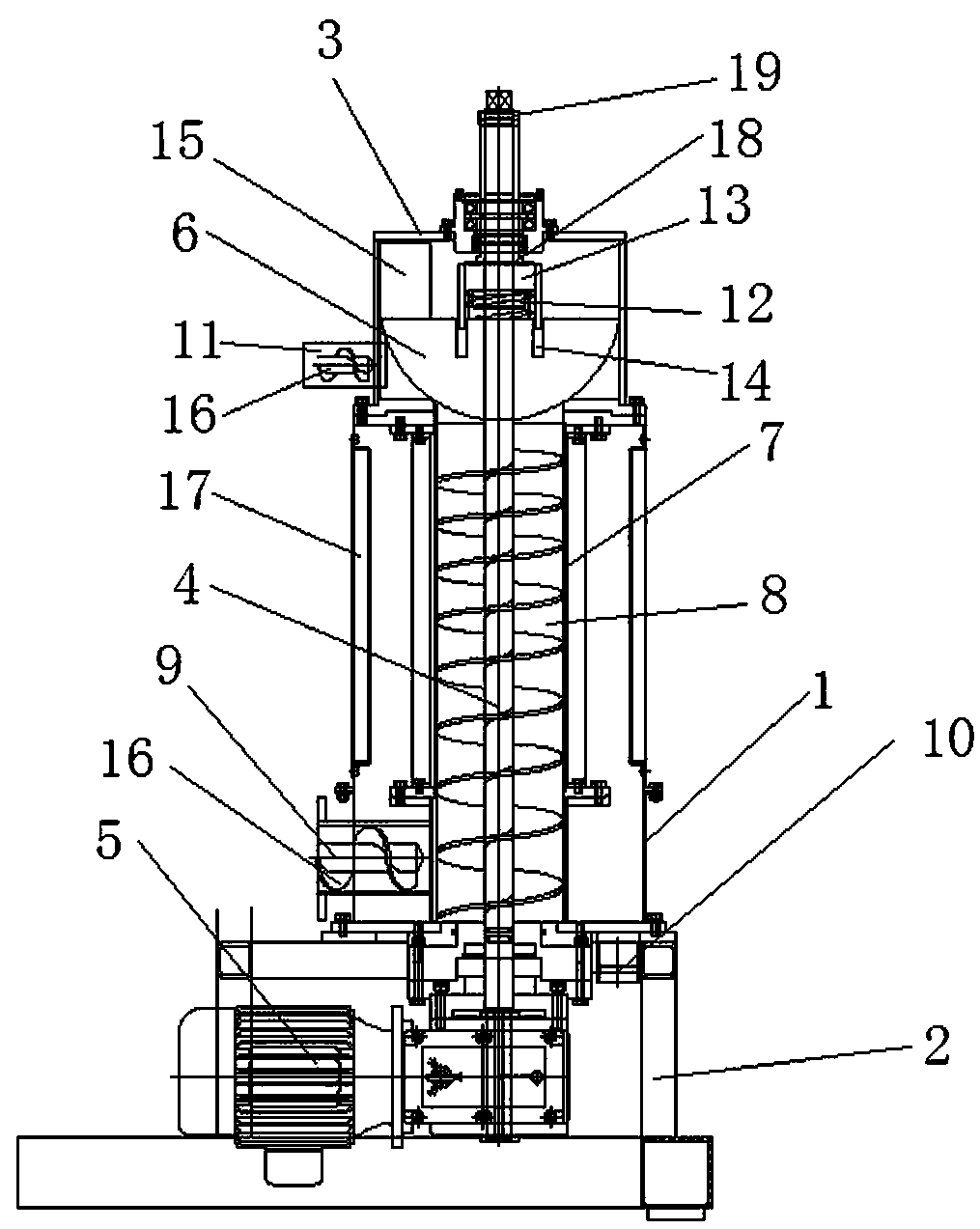

[0023] Embodiment 1: as figure 1 As shown, a vertical solid-liquid separator for kitchen and fruit and vegetable garbage that is not easy to be blocked includes a vertical cylinder 1, a bracket 2 is provided under the vertical cylinder 1, and a discharge bin is provided on the top of the vertical cylinder 1 3. A number of observation doors 17 are provided on the side wall of the vertical cylinder 1 to facilitate observation and inspection of the inside of the vertical cylinder 1 . The vertical barrel 1 is provided with a screw shaft 4, the bottom of the screw shaft 4 protrudes from the bottom of the vertical barrel 1 and is connected with the motor 5 through a coupling; It is connected with the top of the discharge bin 3 through a bearing, and the screw shaft 4 is covered with an extrusion block 6, which is located in the discharge bin, and the extrusion block 6 is slidingly connected with the screw shaft 4, and the extrusion block 6 is hemispherical The extrusion block 6 div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com