Hydrostatic actuator with a split dynamic seal portion

A dynamic sealing and hydrostatic technology, applied in fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of increased unit complexity, unfavorable thermal efficiency, and no longer guaranteed, so as to simplify the construction process, improve flexibility, Effect of reliable sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

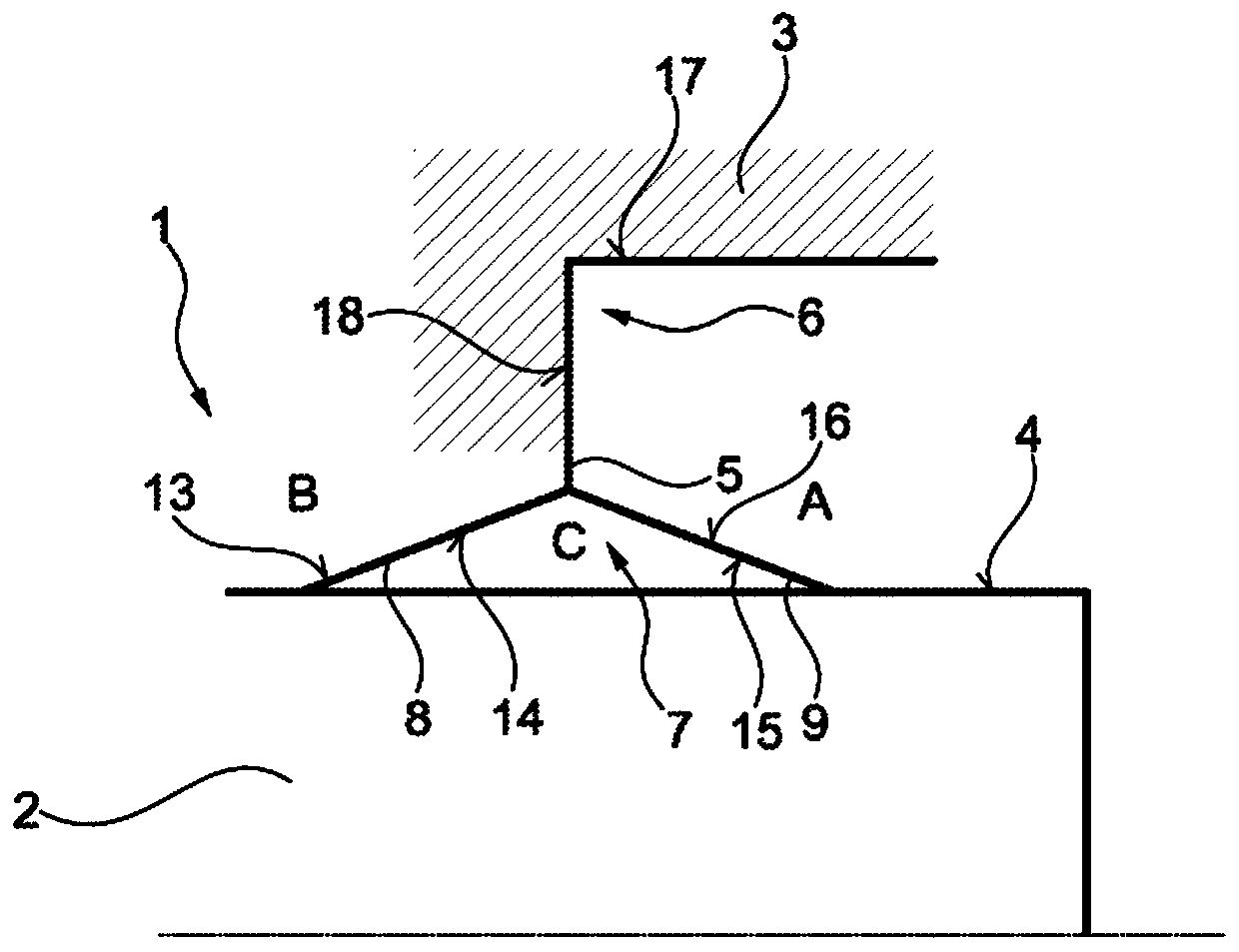

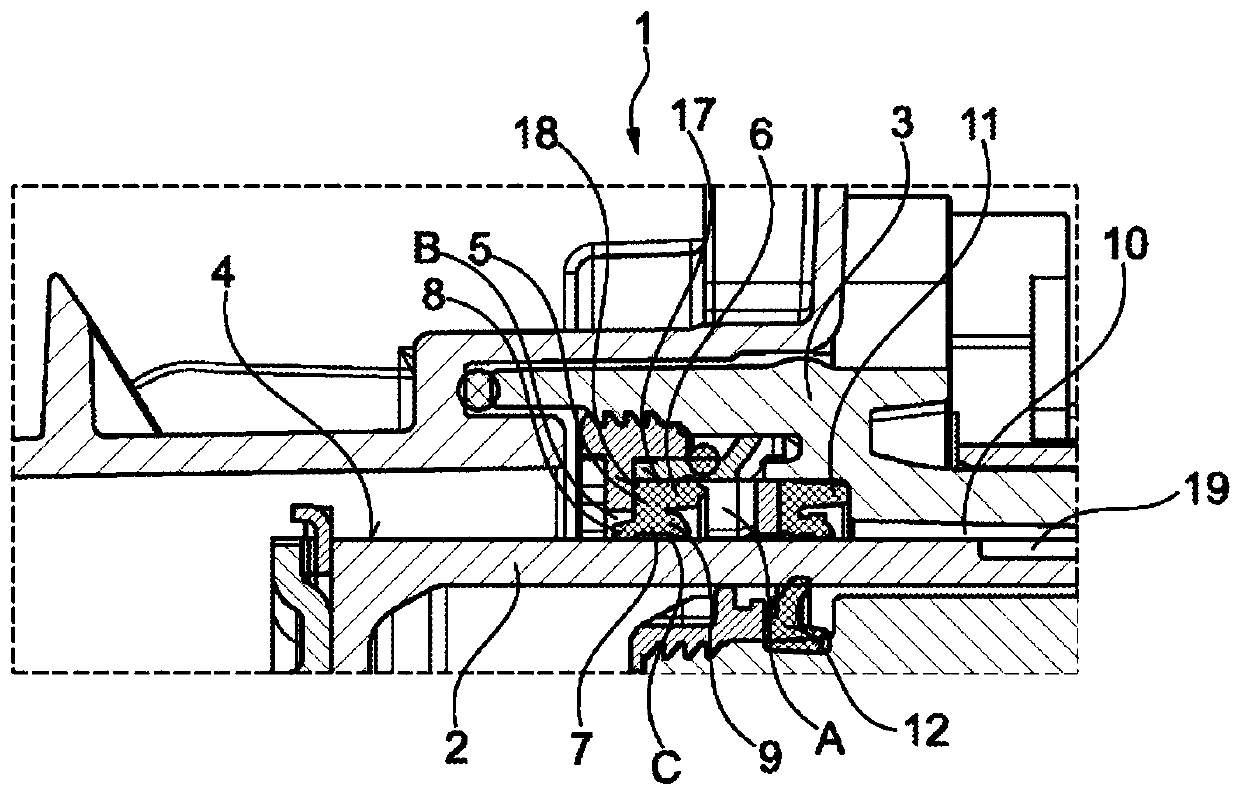

[0027] figure 1 A schematic diagram of a hydrostatic actuator 1 according to the invention is shown. The hydrostatic actuator has a piston 2 arranged around an axis of rotation, which is arranged longitudinally displaceable within a housing 3 , which is mounted, for example, fixed to a motor. The piston 2 has a radially outwardly directed casing surface 4 which has a surface characteristic such that a seal 5 can bear against the casing surface in an effective and completely sealing manner. The seal 5 can be divided into a fastening area 6 and a sealing lip area 7 . The fastening area 6 is designed as a static seal, since the fastening area does not perform a relative movement with respect to the housing 3 . In contrast to this, the sealing lip region 7 is designed dynamically, since the piston 2 can be displaced longitudinally, so that a relative movement occurs between the sealing lip region 7 and the piston 2 .

[0028] In order to achieve effective sealing even under cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com