Method for producing chemically toughened glass

A technology of strengthening glass and manufacturing method, which is applied in the field of chemically strengthening glass, can solve the problems of glass strength reduction, chemical strengthening temperature conditions, time constraints, etc., and achieve the effect of improving surface strength, high surface strength, and simple temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated concretely, this invention is not limited to these Examples and a comparative example.

[0117] [Production of chemically strengthened glass]

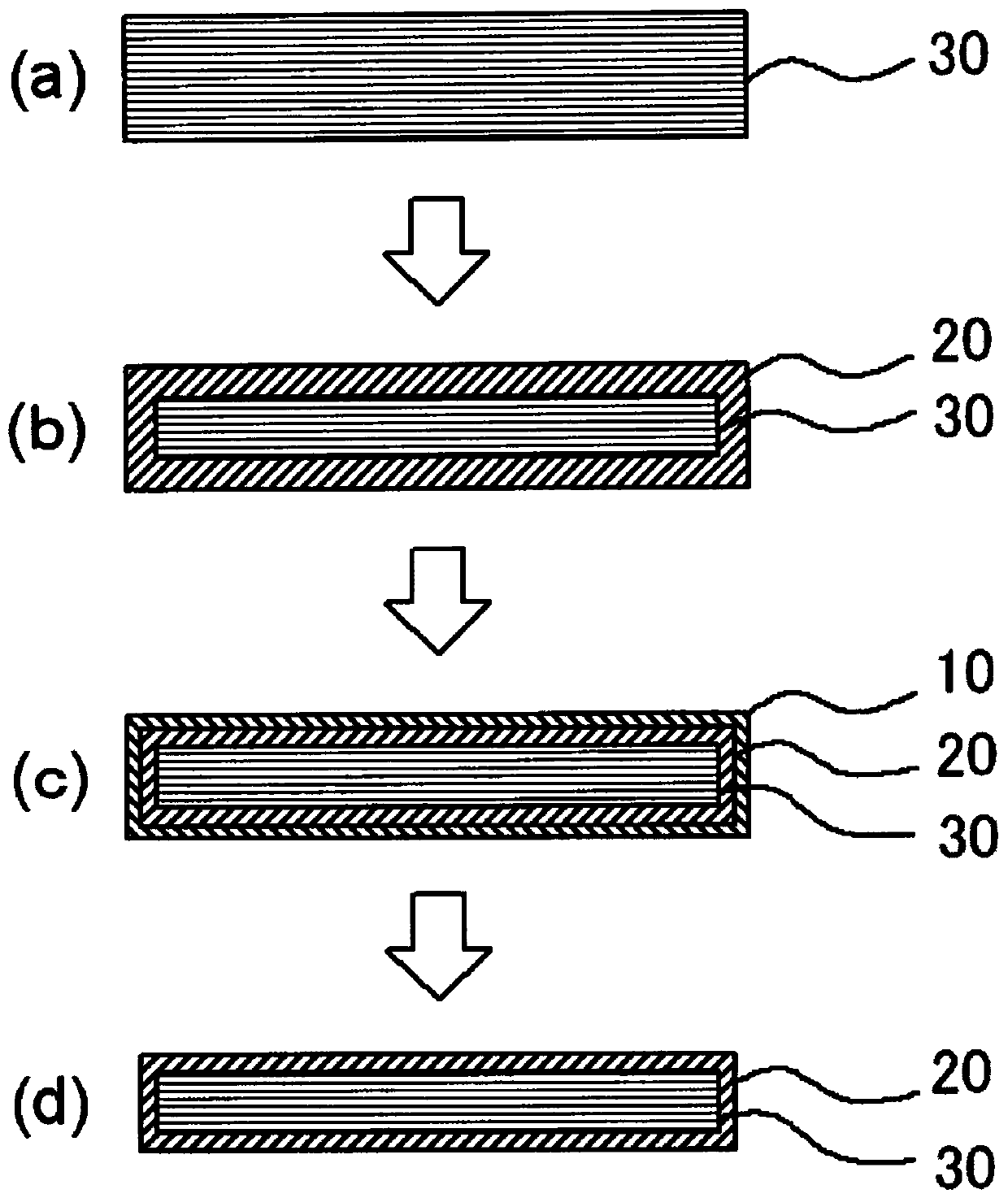

[0118] After performing the chemical strengthening process under the conditions shown below, an acid treatment process, an alkali treatment process, and a grinding process were sequentially performed, and chemically strengthened glass was produced. In addition, about each Example and a comparative example, the presence or absence of each process is shown in Tables 1 and 2.

[0119] (chemical strengthening process)

[0120] The material of the inorganic salt was added to a SUS cup so that the composition and pH shown in Tables 1 and 2 were obtained, and the molten salt was prepared by heating with a mantle heater to the temperature shown in Tables 1 and 2. Prepare aluminosilicate glasses A to C with a plan view of 50 mm x 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com