Nano anode material for lithium-ion primary battery and preparation method thereof

A negative electrode material, lithium-ion technology, applied in the field of nano-negative electrode materials for lithium-ion primary batteries and its preparation, can solve problems that cannot meet the needs of large-scale energy storage facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

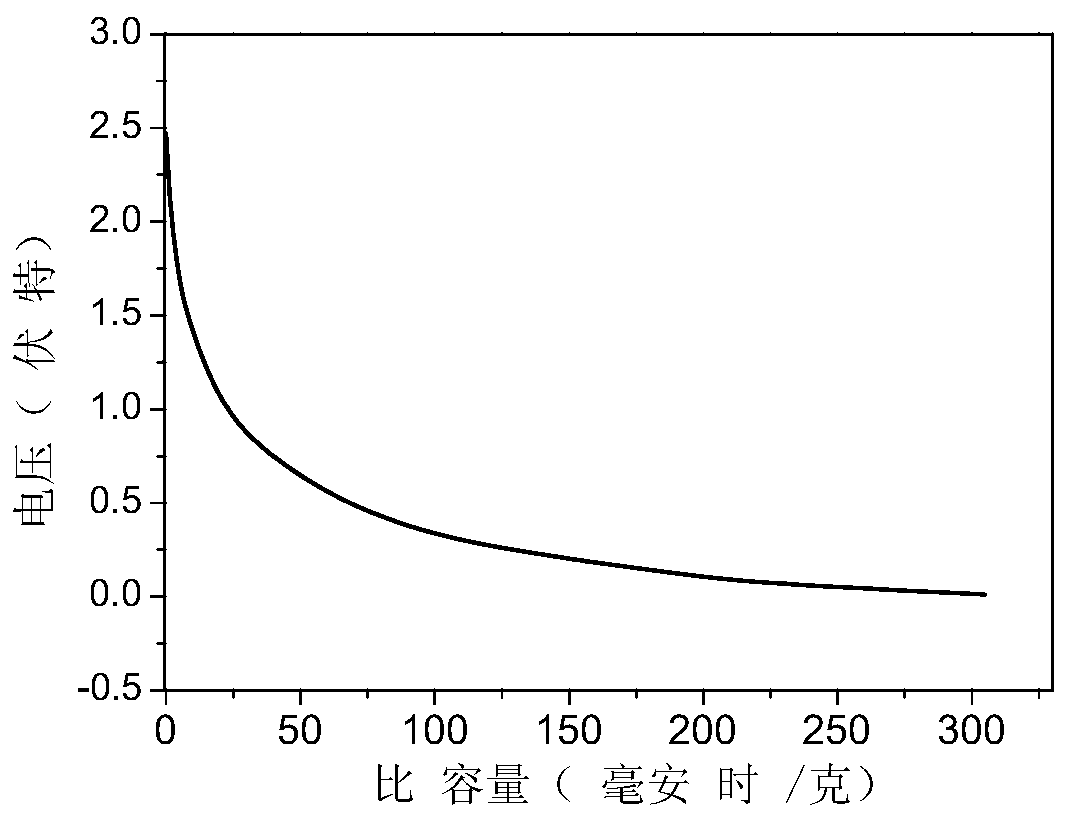

Examples

Embodiment 1

[0022] Said lithium-ion primary battery uses a nano negative electrode material of Li 4 Nb 3 o 8 nanofibers; the Li 4 Nb 3 o 8 Preparation of nanofibers with ethanol

[0023] Niobium, lithium acetylacetonate and polyvinylpyrrolidone are used as reactant raw materials, and a mixed solution composed of ethanol and acetic acid is used as a solvent.

[0024] The preparation method of described lithium-ion primary battery nano negative electrode material, comprises the following steps:

[0025] (1) Preparation of electrospinning precursor solution: First, dissolve 1g of niobium ethoxide, 0.11g of lithium acetylacetonate and 0.5g of polyvinylpyrrolidone in a mixed solution consisting of 4ml of analytically pure ethanol and 2ml of analytically pure acetic acid, and stir for 5 hours to obtain Electrospinning precursor solution;

[0026] (2) Preparation of Li 4 Nb 3 o 8 Nanofiber: Pour the electrospinning precursor obtained in step (1) into a syringe for electrospinning

[0...

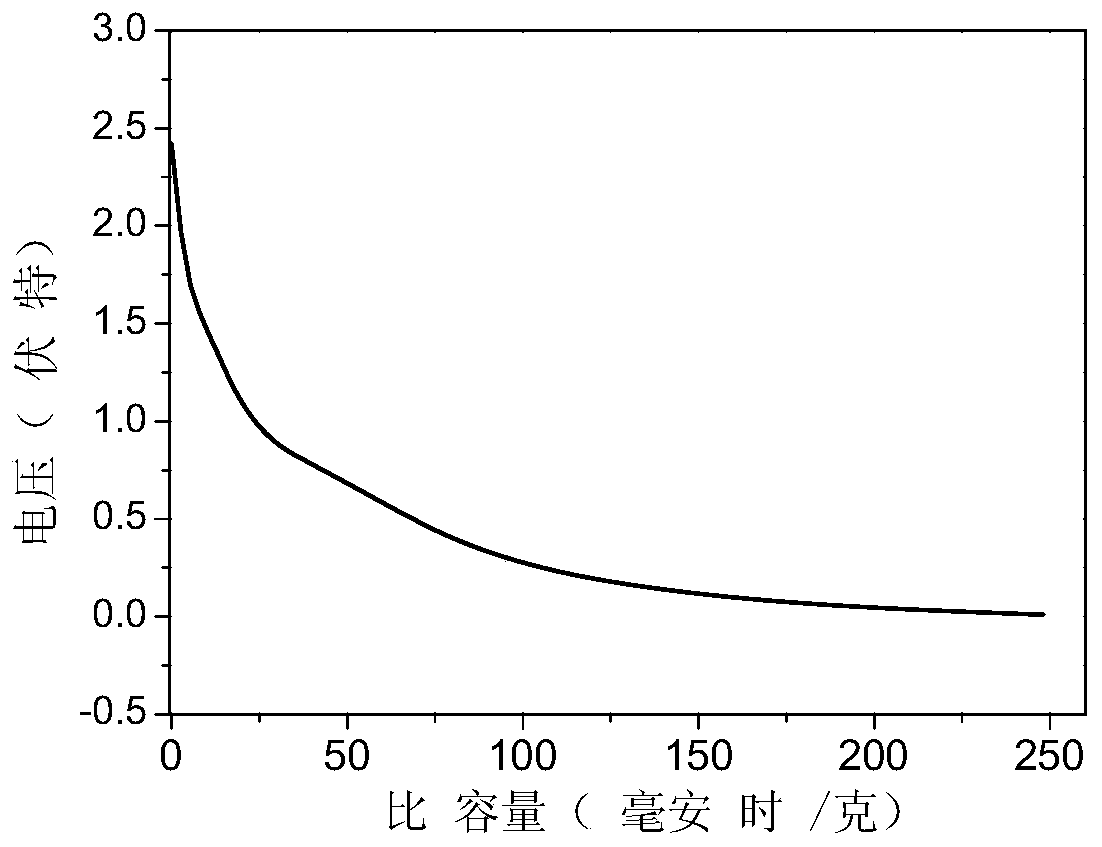

Embodiment 2

[0034] The preparation method of described lithium-ion primary battery nano negative electrode material, comprises the following steps:

[0035](1) Preparation of electrospinning precursor solution: First, dissolve 1.5g of niobium ethoxide, 0.11g of lithium acetylacetonate and 0.5g of polyvinylpyrrolidone in a mixed solution consisting of 4ml of analytically pure ethanol and 2ml of analytically pure acetic acid, and stir for 5 hours Obtain the electrospinning precursor solution;

[0036] (2) Preparation of Li 4 Nb 3 o 8 Nanofiber: Pour the electrospinning precursor obtained in step (1) into a syringe for electrospinning

[0037] Silk, spinning conditions are: receiving distance 12cm, spinning voltage 12kV, spinning speed is 0.5mh / h; then the collected

[0038] Li 4 Nb 3 o 8 Nanofibers, where the heating rate is 3°C

[0039] / min for heat treatment.

[0040] Li will be prepared 4 Nb 3 o 8 The nanofibers, the conductive agent and the binder were placed in a mortar ac...

Embodiment 3

[0044] The preparation method of described lithium-ion primary battery nano negative electrode material, comprises the following steps:

[0045] (1) Preparation of electrospinning precursor solution: First, dissolve 1g of niobium ethoxide, 0.15g of lithium acetylacetonate and 0.5g of polyvinylpyrrolidone in a mixed solution consisting of 4ml of analytically pure ethanol and 2ml of analytically pure acetic acid, and stir for 5 hours to obtain Electrospinning precursor solution;

[0046] (2) Preparation of Li 4 Nb 3 o 8 Nanofiber: Pour the electrospinning precursor obtained in step (1) into a syringe for electrospinning

[0047] Silk, spinning conditions are: receiving distance 12cm, spinning voltage 12kV, spinning speed is 0.5mh / h; then the collected

[0048] Li 4 Nb 3 o 8 Nanofibers, where the heating rate is 3°C

[0049] / min for heat treatment.

[0050] Li will be prepared 4 Nb 3 o 8 The nanofibers, the conductive agent and the binder were placed in a mortar acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com