Bracket component for mounting glass plate

A glass plate and component technology, applied in the direction of application, thin plate connection, connecting components, etc., can solve the problems of low installation efficiency and increase the difficulty of production and installation, so as to improve installation efficiency, save installation steps, and improve aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

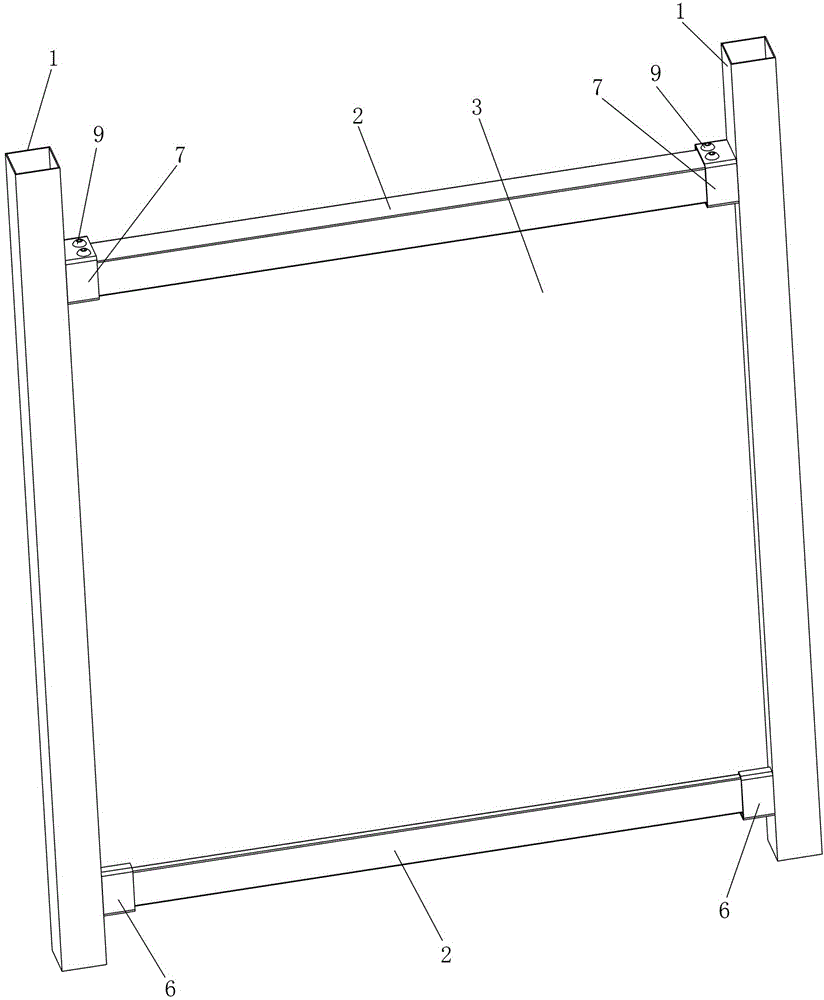

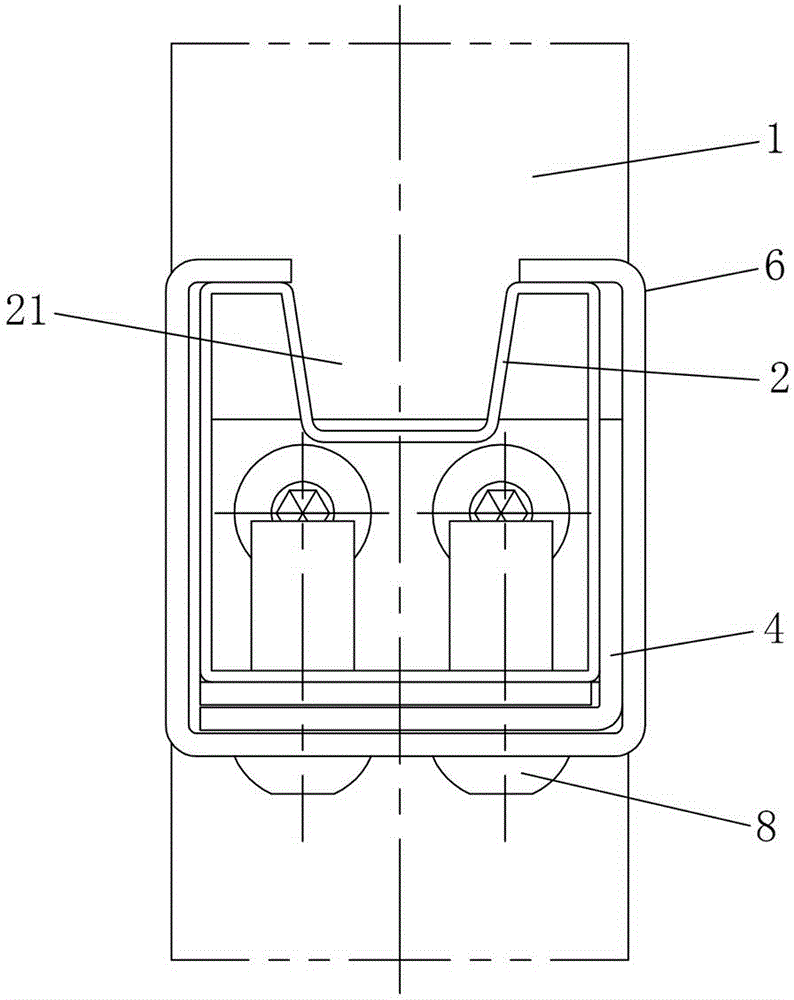

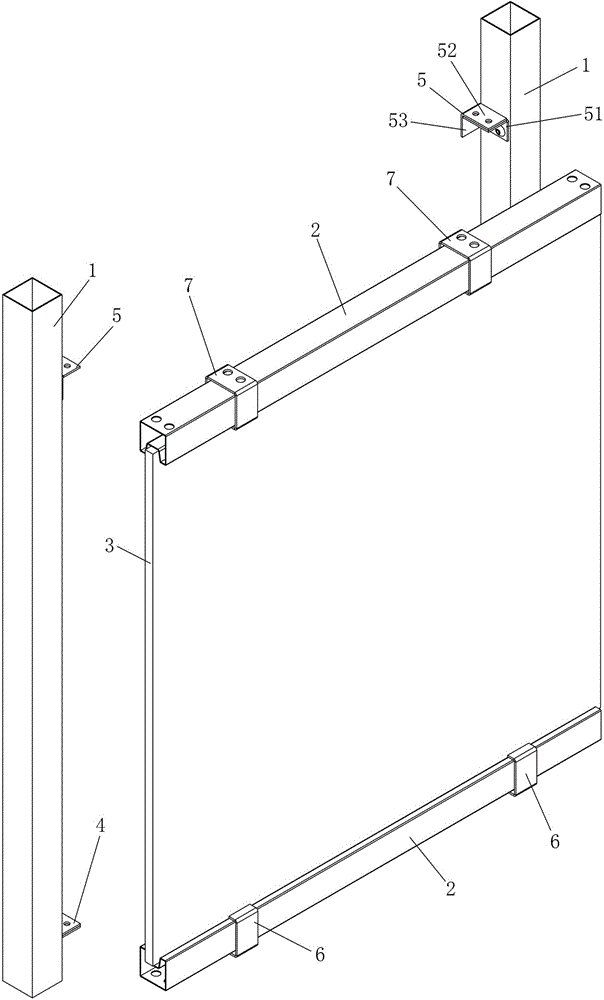

[0028] Figure 1 to Figure 7 It shows an embodiment of the bracket assembly for installing glass plates of the present invention, including two vertical beams 1 arranged at intervals and two clamping rods 2 clamping the glass plate 3 from the upper and lower ends, and the two vertical beams 1 are provided with a first connecting piece 4 for connecting the clamping rod 2 at the lower end of the glass plate 3 and a second connecting piece 5 for connecting the clamping rod 2 at the upper end of the glass plate 3 . When the bracket assembly of the present invention is used to install the glass plate 3, the glass plate 3 is clamped between two clamping rods 2, and the two clamping rods 2 are respectively fixed by the first connecting piece 4 and the second connecting piece 5 respectively. The installation is completed on the two vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com