Mask plate and preparation method thereof

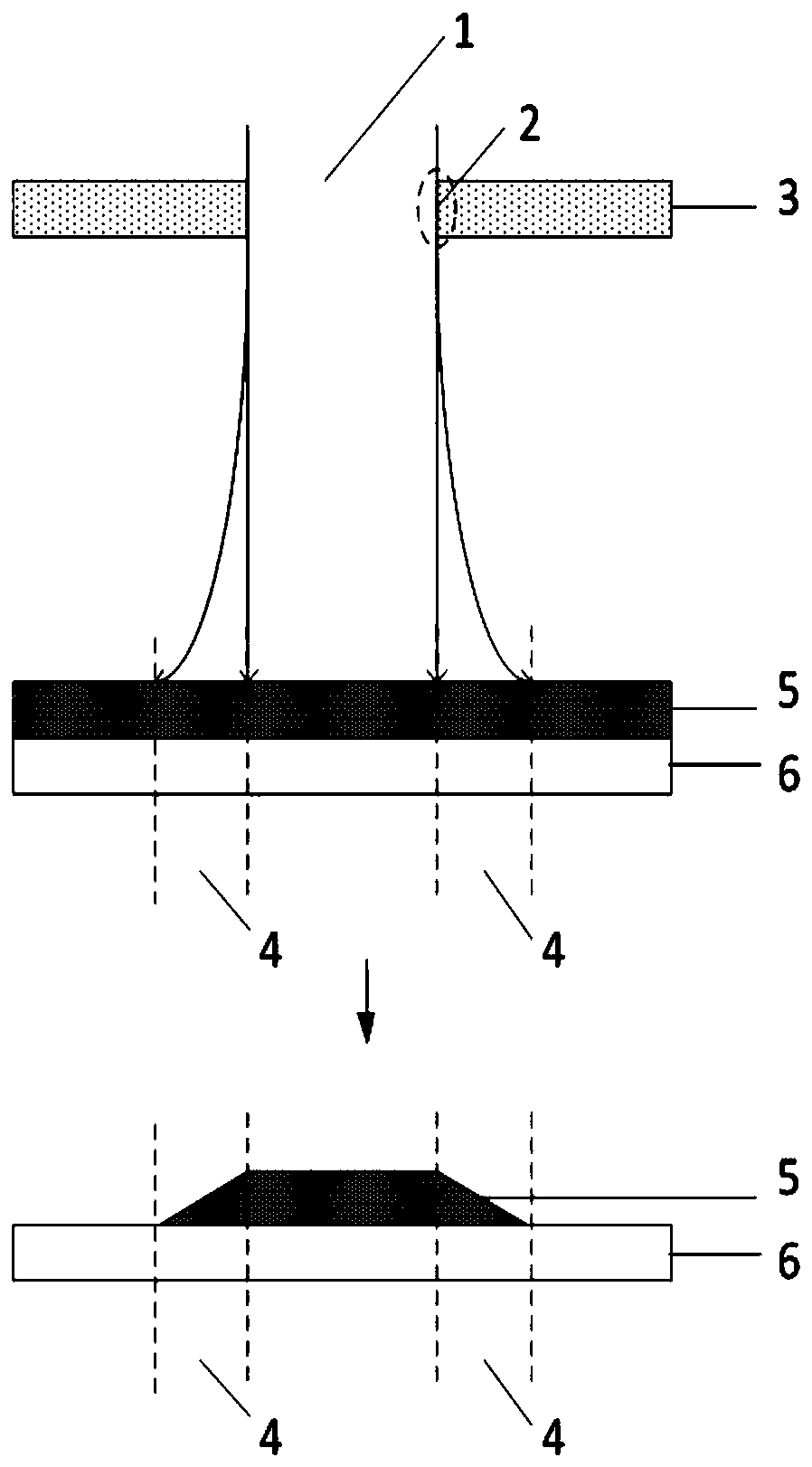

A mask plate and mask plate technology, which is applied in the field of communication, can solve the problems of large size, poor pattern film thickness uniformity, and large film pattern size, so as to reduce the area with insufficient exposure energy, realize refined structure, and enhance The effect of degree of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

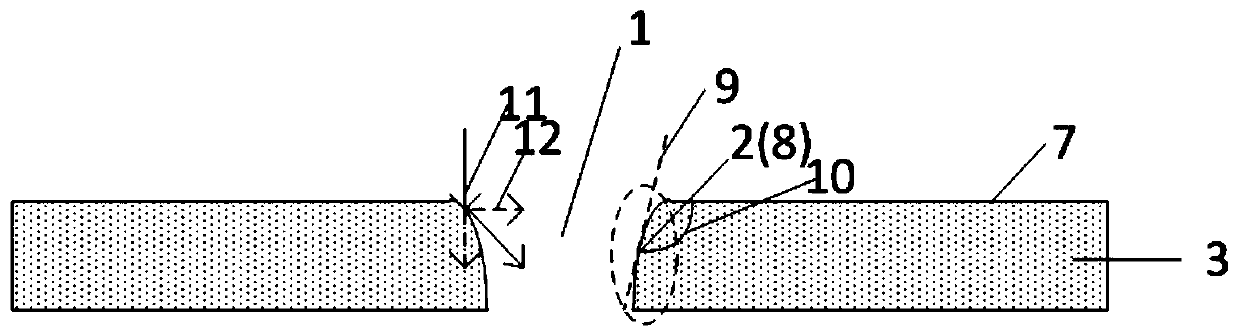

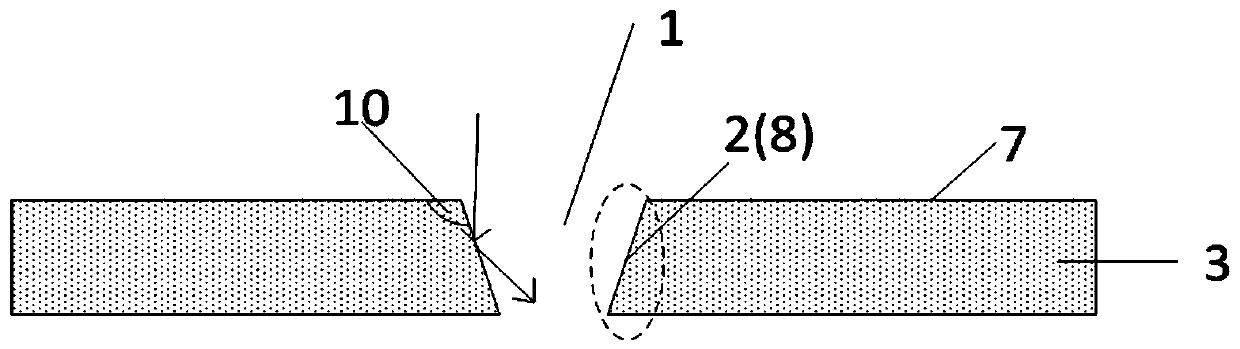

[0042] The embodiment of the present application provides a mask plate, such as figure 2 As shown, at least one opening area 1 is included, and the side 2 of the opening area 1 is a slope with a set angle with the upper surface 7 of the mask plate 3; and at least the tangent 9 between the first part 8 of the slope and the The included angle 10 of the upper surface is greater than 90°, so that the light 11 incident from the upper surface 7 of the mask 3 passes through the reflection of the first part 8 to produce a component parallel to the direction of the plane where the mask 3 is located 12. That is, the light incident from the upper surface of the mask plate is reflected to the opening area through the first part.

[0043] In the mask plate provided by the embodiment of the present application, since the side of the opening area is an inclined plane with a set angle with the upper surface of the mask plate, and the inclined plane has a first angle at which the tangent lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com