Steam-air preheating device and system

An air preheating and steam technology, applied in the boiler field, can solve the problems of reducing the heat absorption rate of the system, prone to water hammer, waste of condensed water energy, etc., to reduce steam extraction, improve heat exchange efficiency, and avoid water hammer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

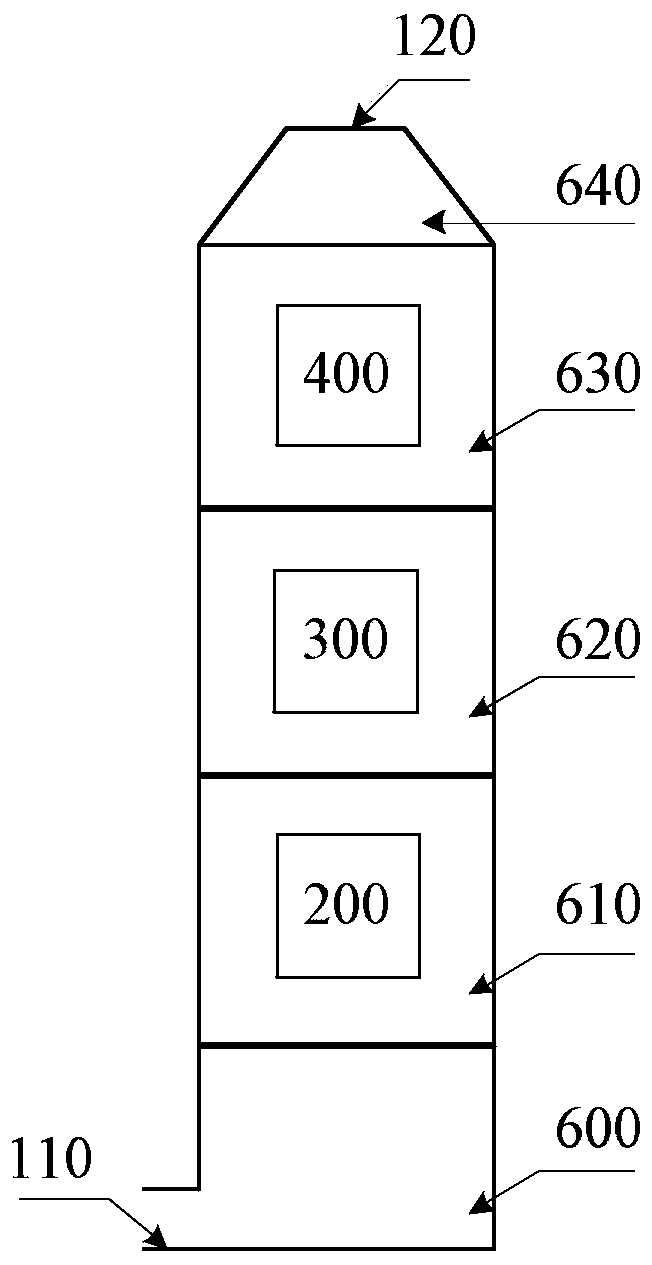

[0036] At present, boilers in power plants mostly use steam-type air preheaters, and the primary air is preheated through two-stage steam heating surfaces in the low-pressure section and the high-pressure section in turn. The primary air is first heated by the low-pressure heating surface of the turbine extraction steam, and then heated by the high-pressure heating surface of the steam drum extraction. The condensed water produced by the two-stage steam heating is sent to the deaerator through the drain pipe respectively.

[0037] However, the above-mentioned air preheater is only heated by extracting steam from the low-pressure steam turbine and steam from the high-pressure drum, and the extraction of steam is relatively large. The condensed water generated after the two-stage heating directly enters the deaerator, wasting the energy of the condensed water. The high-quality performance of the steam is seriously lost, and the heat absorption rate of the system is reduced. In ad...

Embodiment 2

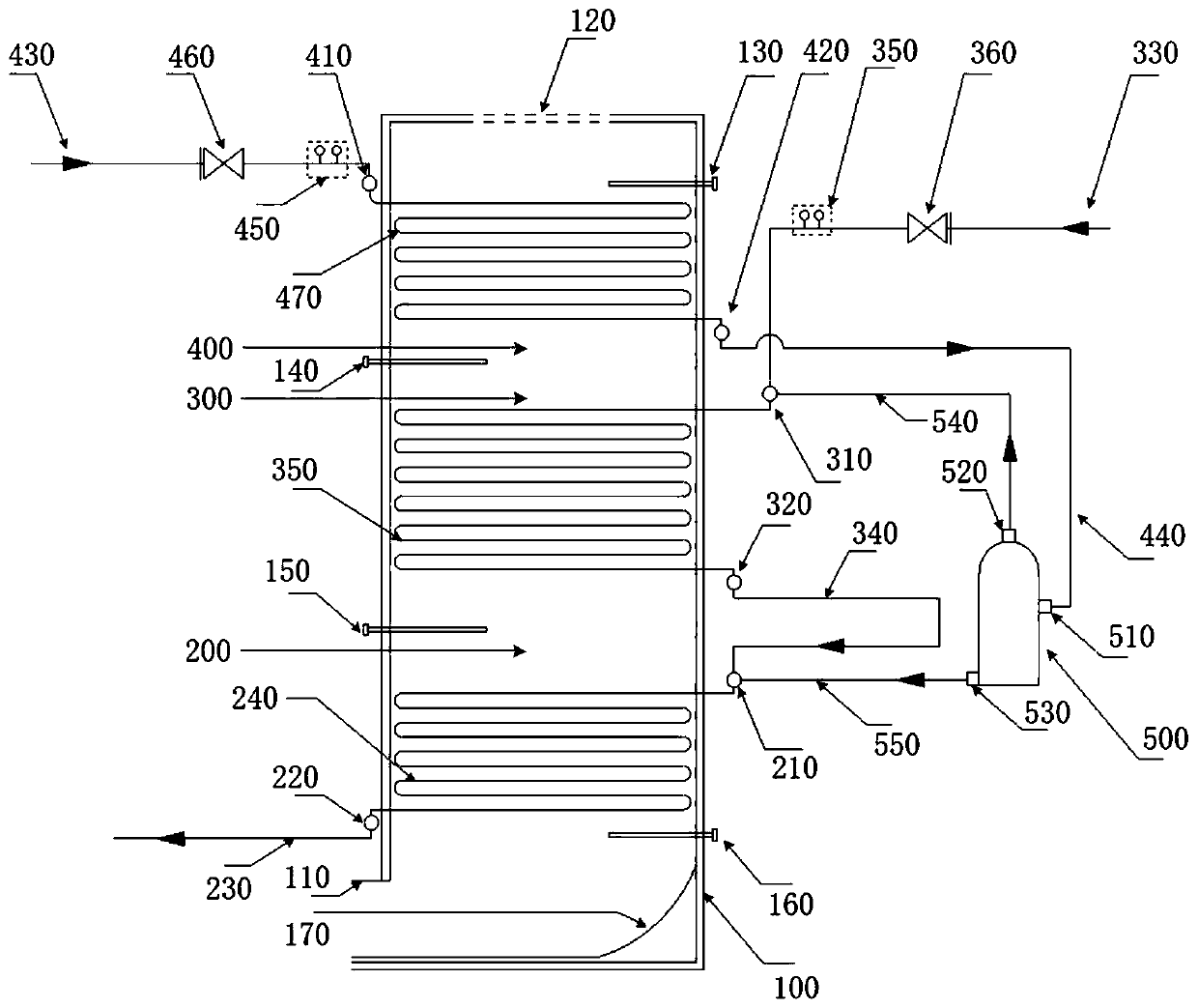

[0053] figure 2 A schematic structural diagram of a steam air preheating device provided in Embodiment 2 of the present invention, on the basis of the above technical solution, optionally, refer to figure 2 , the first steam extraction pipeline 430 is a steam drum extraction pipeline, and the inlet header 410 of the high-pressure steam heat exchange section 400 communicates with the boiler drum through the steam drum extraction pipeline;

[0054] The second steam extraction pipe 330 is a steam turbine extraction pipe, and the inlet header 310 of the low-pressure steam heat exchange section 300 communicates with the steam turbine through the steam turbine extraction pipe.

[0055] The drum steam extraction pipe can extract the high-pressure steam in the boiler drum and enter the high-pressure steam heat exchange section 400 through the inlet header 410 .

[0056] The steam turbine extraction pipeline enters the low-pressure steam heat exchange section 300 through the inlet h...

Embodiment 3

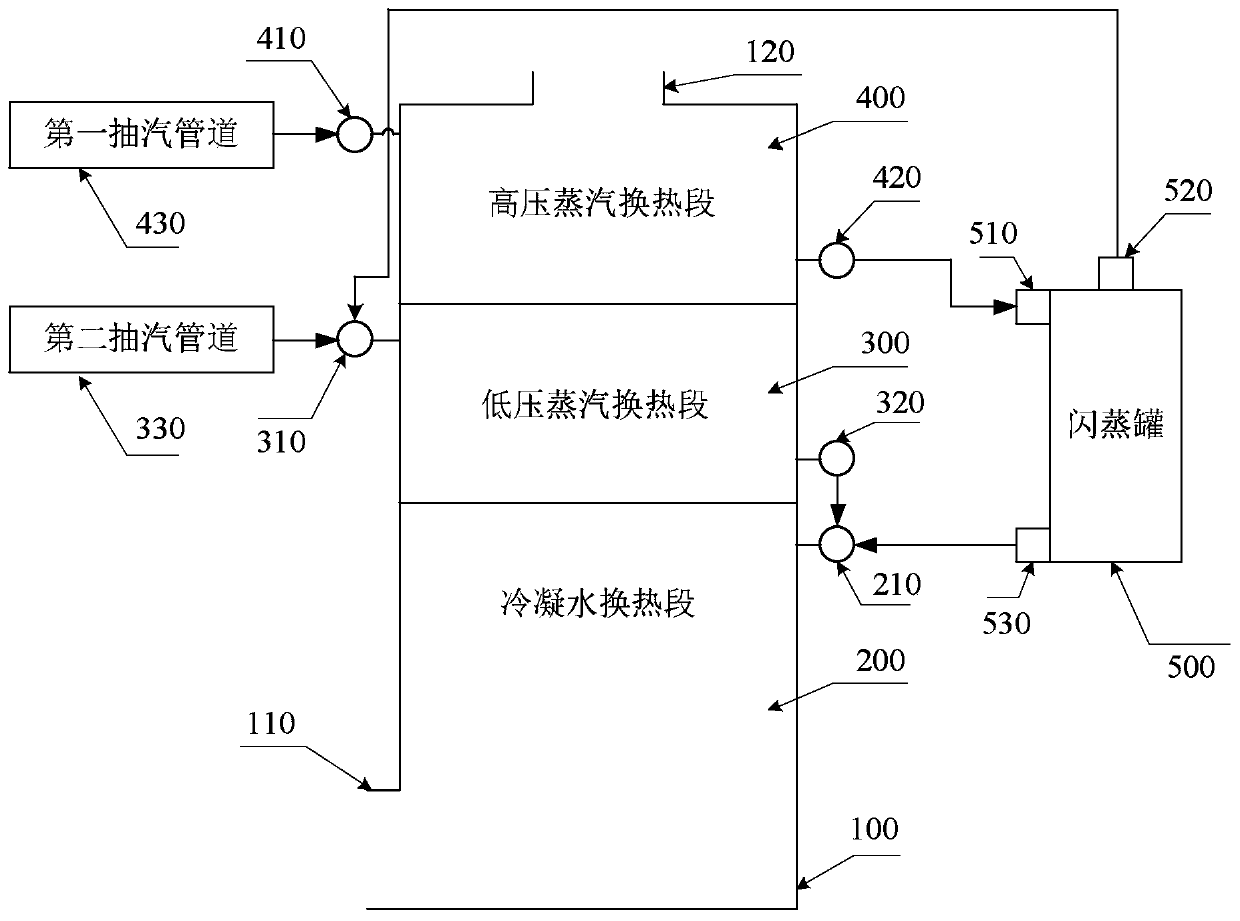

[0092] This embodiment also provides a steam air preheating system, Figure 4 It is a schematic structural diagram of a steam air preheating system provided by an embodiment of the present invention. Optionally, refer to Figure 4 , the system includes the steam air preheating device provided by any embodiment of the present invention; wherein,

[0093] The first extraction pipe 430 of the high-pressure steam heat exchange section 400 is connected to the boiler drum 710;

[0094] The second steam extraction pipeline 330 of the low-pressure steam heat exchange section 300 is connected to the steam turbine 720;

[0095] The fourth drain pipe 230 of the condensed water heat exchange section 200 is connected with the deaerator 730 .

[0096] In actual application, the air to be preheated at the inlet 110 can be driven by the fan to flow into the box 100, and then pass through the condensed water heat exchange section 200, the low-pressure steam heat exchange section 300, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com