Disassembly tool and method of compression spring in cylinder block

A technology of compressing springs and disassembly tools, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as difficult repairs, difficult disassembly and installation, time-consuming and laborious disassembly methods, and achieve the goal of improving practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

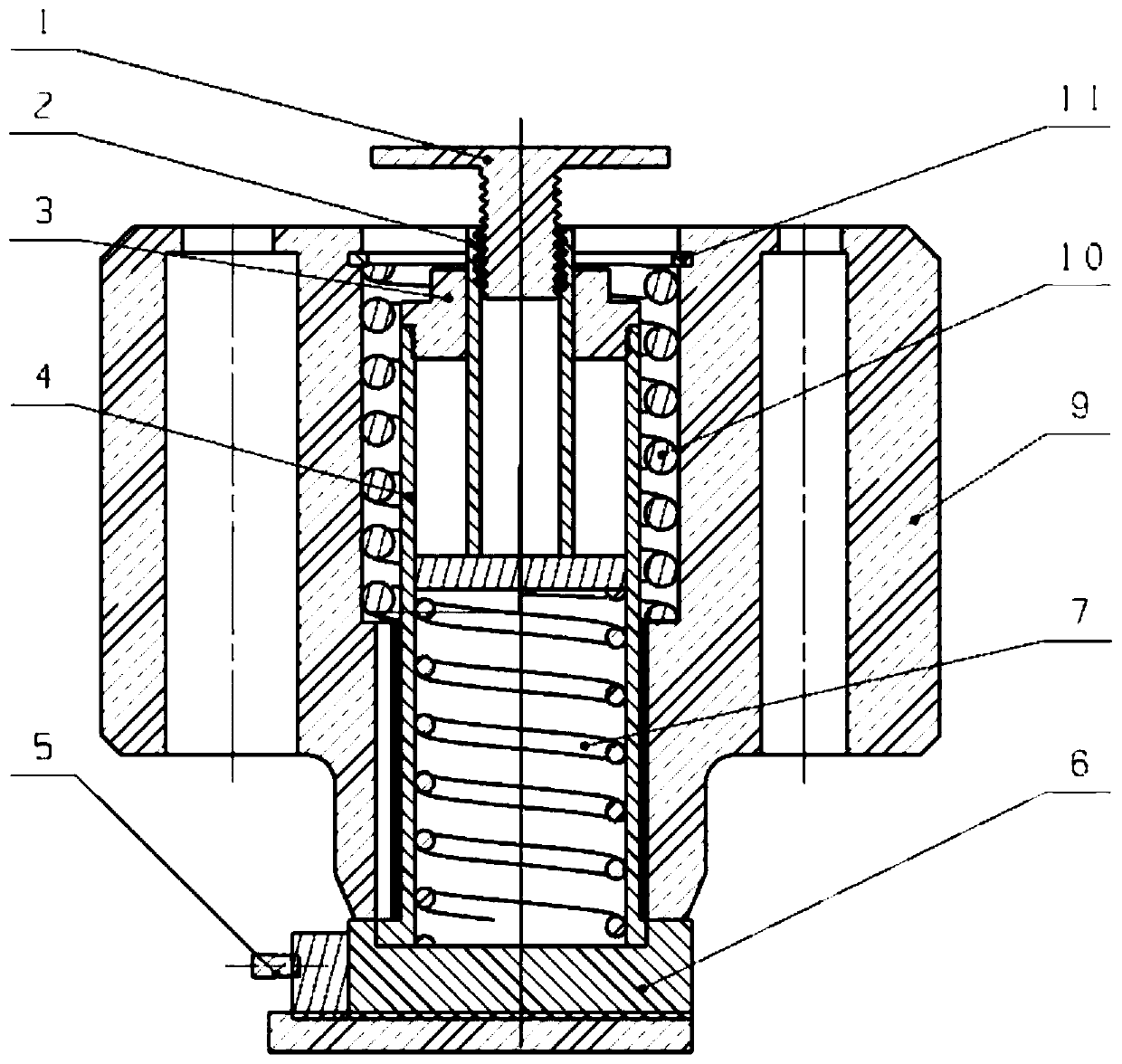

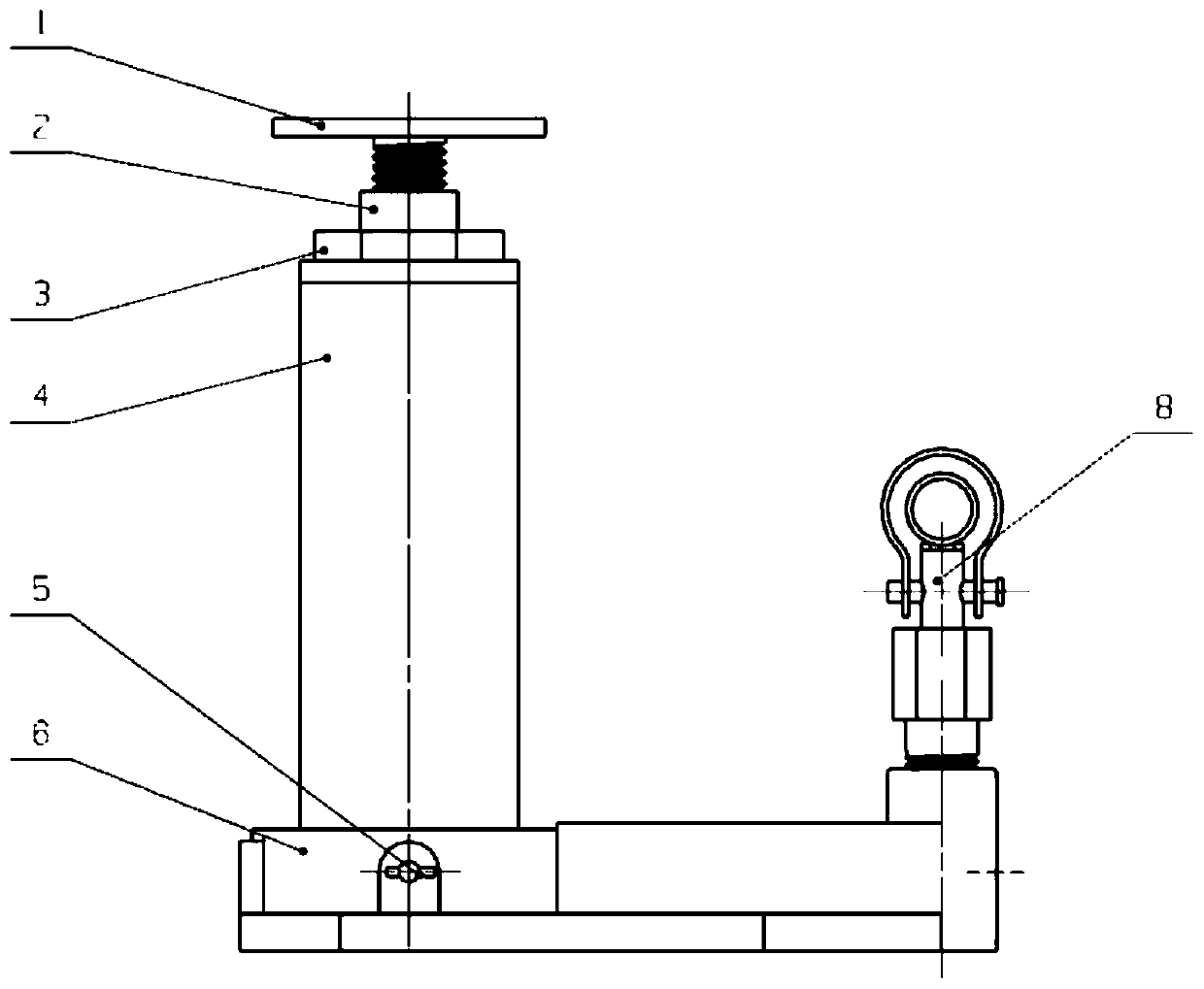

[0023] see figure 1 and figure 2 , a disassembly and assembly tool for the compression spring inside the cylinder body, including a pressure plate 1, a piston rod 2, a cylinder head 3, a cylinder barrel 4, an oil drain bolt 5, a base 6, a hydraulic spring 7, a pressing mechanism 8, a cylinder body 9, a compression Spring 10, circlip 11;

[0024] The cylinder head 3 and the cylinder barrel 4 are threadedly connected, the center of the cylinder head 3 has a through hole, the piston rod 2 can move axially along the through hole, the hydraulic spring 7 is located in the cylinder barrel 4, and the pressing mechanism 8 is hinged to the base 6 . The pressing plate 1 and the piston rod 2 are threadedly connected and can move up and down with the piston rod 2 axially, and the pressing plate 1 presses the spring compression 10 in the cylinder 9 downward through the downward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com