A kind of matte oleophobic and hydrophobic facing adhesive film paper and its preparation method and application

A film-coated, matte-type technology that is used in papermaking, paper, paper coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

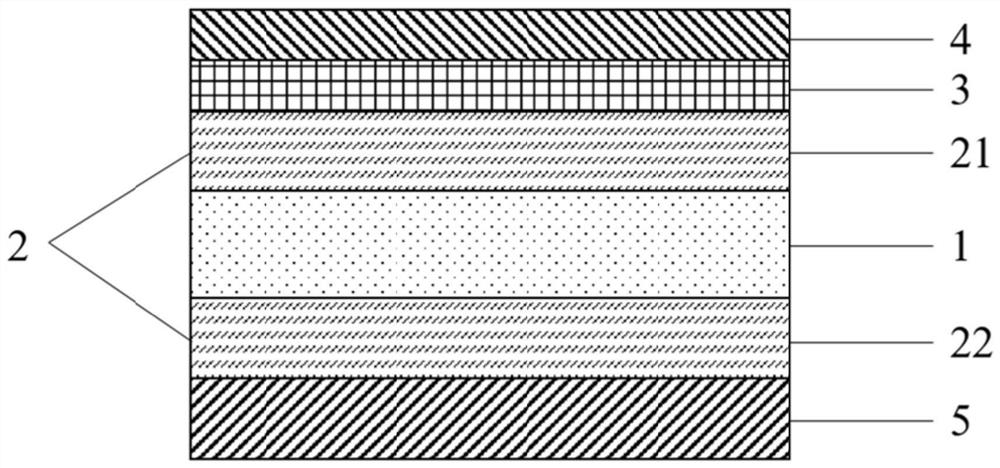

Image

Examples

Embodiment 1

[0058] In this case, the preparation method of the matte oleophobic and hydrophobic facing adhesive film paper is as follows:

[0059] 1) First gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of impregnated resin per square meter of base paper is 80g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, and 150°C respectively) , to obtain the semi-finished product A of printed decorative paper.

[0060] 2) Second gluing: Spray matte melamine formaldehyde resin on the front of the printed decorative paper semi-finished product A, and the matte melamine formaldehyde resin is composed of the following raw materials in parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, 1.2 parts of curing agent, 0.2 parts of release agent, 0.2 parts of anti-sticking agent, and 0.2 parts of dust remover. These raw materials are weighed according to the proportion, mixed and stirr...

Embodiment 2

[0068] In this case, the preparation method of the matte oleophobic and hydrophobic facing adhesive film paper is as follows:

[0069] 1) First gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of impregnated resin per square meter of base paper is 80g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, and 150°C respectively) , to obtain the semi-finished product A of printed decorative paper.

[0070] 2) Second gluing: Spray matte melamine formaldehyde resin on the front of the printed decorative paper semi-finished product A, and the matte melamine formaldehyde resin is composed of the following raw materials in parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, 1.2 parts of curing agent, 0.2 parts of release agent, 0.2 parts of anti-sticking agent, and 0.2 parts of dust remover. These raw materials are weighed according to the proportion, mixed and stirr...

Embodiment 3

[0078] In this case, the preparation method of the matte oleophobic and hydrophobic facing adhesive film paper is as follows:

[0079] 1) First gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of impregnated resin per square meter of base paper is 80g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, and 150°C respectively) , to obtain the semi-finished product A of printed decorative paper.

[0080] 2) Second gluing: Spray matte melamine formaldehyde resin on the front of the printed decorative paper semi-finished product A, and the matte melamine formaldehyde resin is composed of the following raw materials in parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, 1.2 parts of curing agent, 0.2 parts of release agent, 0.2 parts of anti-sticking agent, and 0.2 parts of dust remover. These raw materials are weighed according to the proportion, mixed and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com