MXene nanosheet interlamellar spacing regulation method

A nanosheet and nanosheet technology, applied in the field of surface-modified MXene nanosheets, can solve the problems of hindering ion migration, low energy storage capacity, poor controllability, etc., and achieve the effect of simple operation, various types, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

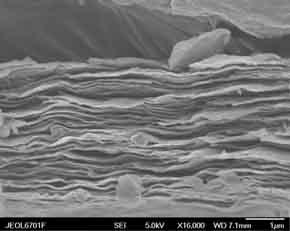

[0024] Step 1, preparation of MXene nanosheets:

[0025] Add 1g of LiF salt to 10ml of 3M hydrochloric acid solution and stir for 0.5h until completely dissolved, slowly add 1g of Ti to the above solution 3 AlC 2 powder. The etching is completed after constant temperature of 24 hours under the condition of 45° C. by water bath method. The etched solution is washed four times by centrifugation, filtration, and water addition, and the pH of the solution is about 6 after washing. After the washed solution was subjected to 3 repeated ultrasonic centrifugation treatments under the protection of argon, an MXene nanosheet solution with a concentration of about 3 mg / ml was obtained;

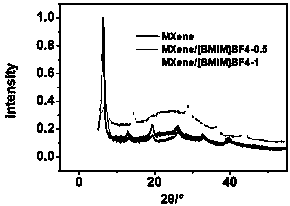

[0026] Step 2, regulating the layer spacing of MXene nanosheets:

[0027] Prepare the MXene solution prepared in step 1 to a solution with a concentration of 0.1mg / ml, take 20ml of the above solution, stir at a high speed under argon protection and 20°C, and then slowly add 10ml of 1-butane with a co...

Embodiment 2

[0030] Step 1, preparation of MXene nanosheets:

[0031] Add 1g of LiF salt to 10ml of 3M hydrochloric acid solution and stir for 0.5h until completely dissolved, slowly add 1g of Ti to the above solution 3 AlC 2 powder. The etching is completed after constant temperature of 24 hours under the condition of 45° C. by water bath method. The etched solution is washed four times by centrifugation, filtration, and water addition, and the pH of the solution is about 6 after washing. After the washed solution was subjected to 3 repeated ultrasonic centrifugation treatments under the protection of argon, an MXene nanosheet solution with a concentration of about 3 mg / ml was obtained;

[0032] Step 2, regulating the layer spacing of MXene nanosheets:

[0033] Prepare the MXene solution prepared in step 1 into a solution with a concentration of 0.1mg / ml, take 20ml of the above solution, stir at a high speed under argon protection and 20°C, and then slowly add 10ml of 1-butylene with ...

Embodiment 3

[0036] Step 1, preparation of MXene nanosheets:

[0037] Add 0.5g of LiF salt to 12M hydrochloric acid solution and stir for 3h until completely dissolved, slowly add 0.5g of Ti to the above solution 2 AlC powder. The etching is completed after constant temperature of 24 hours under the condition of 45° C. by water bath method. The etched solution is washed four times by centrifugation, filtration, and water addition, and the pH of the solution is about 6 after washing. After the washed solution was subjected to 3 repeated ultrasonic centrifugation treatments under the protection of argon, an MXene nanosheet solution with a concentration of about 3 mg / ml was obtained;

[0038] Step 2, regulating the layer spacing of MXene nanosheets:

[0039]Prepare the MXene solution prepared in step 1 into a solution with a concentration of 0.1mg / ml, take 20ml of the above solution, stir at a high speed under nitrogen protection and 40°C, and then slowly add 10ml of 1-ethyl with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com