Extended-range hybrid power control method

A hybrid, power control technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of slow engine speed changes, huge current fluctuations, working power fluctuations, etc., to ensure the stability and safety of power supply performance, ensuring fast response and stable charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0044] Such as Figure 4 Shown, the workflow of the present invention is as follows:

[0045] Build the engine work reference table as follows:

[0046]

[0047] The table construction process mainly includes:

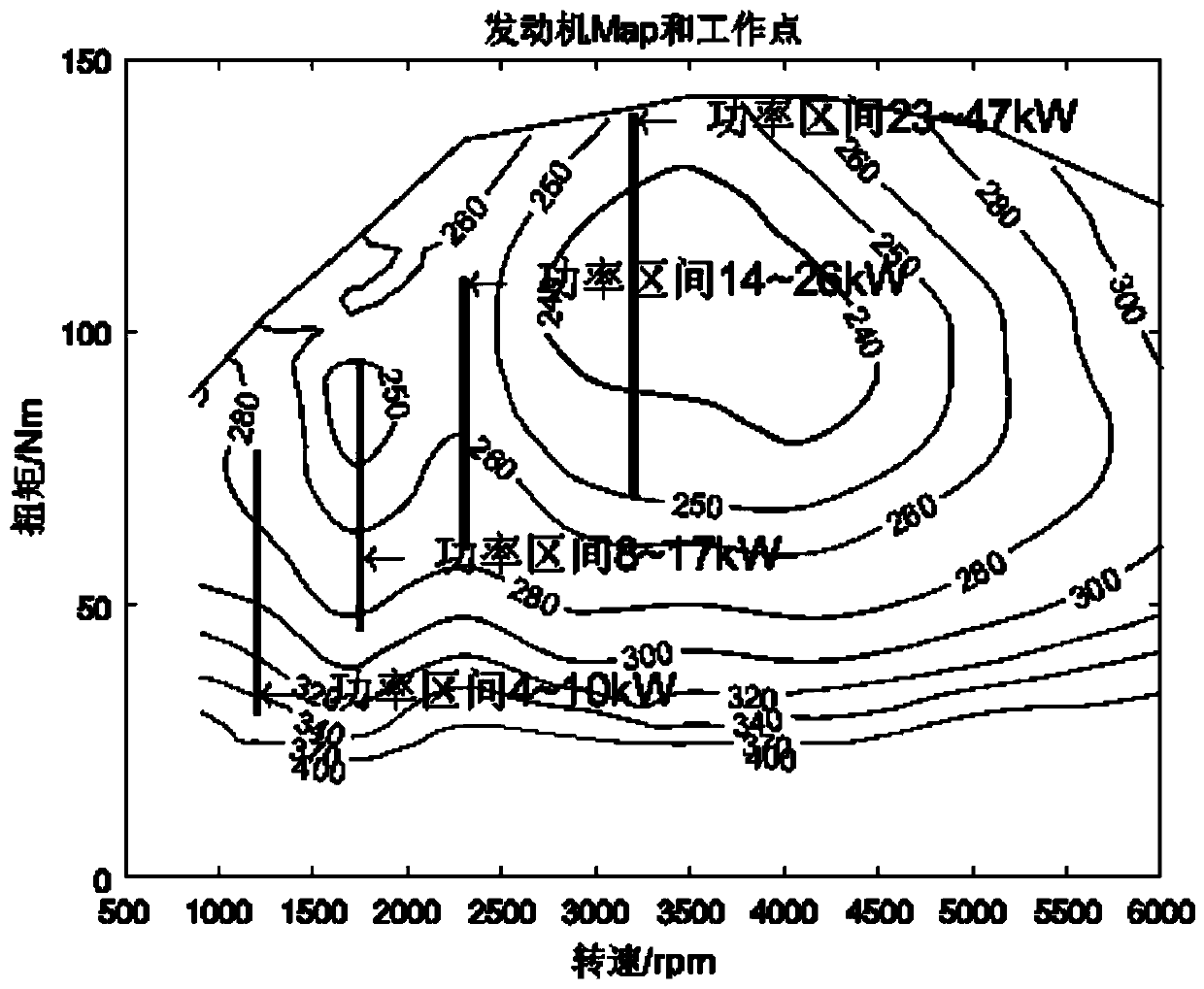

[0048] Determine the fixed speed value of the engine and determine the power range (that is, the target power generation range of the range extender)

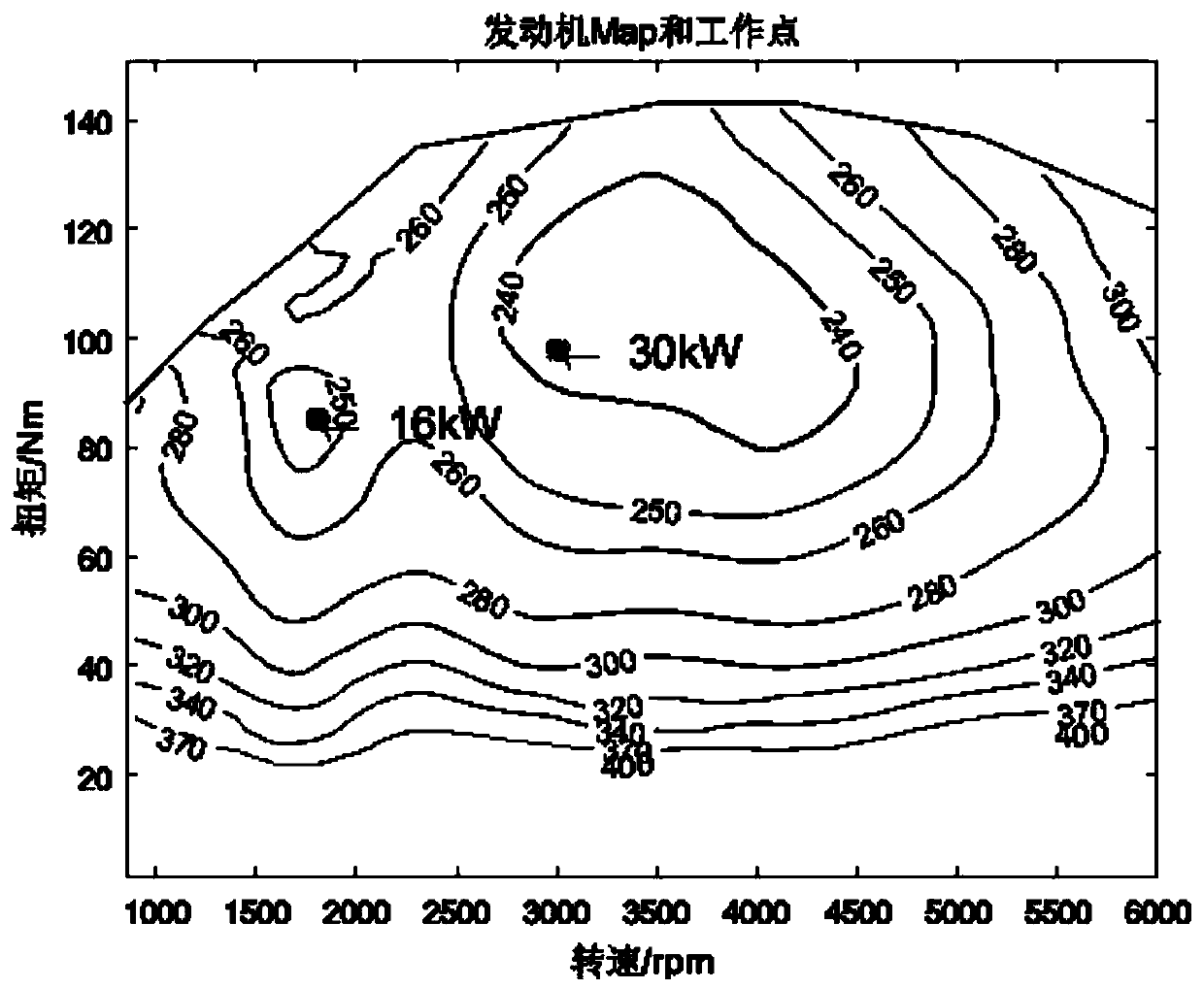

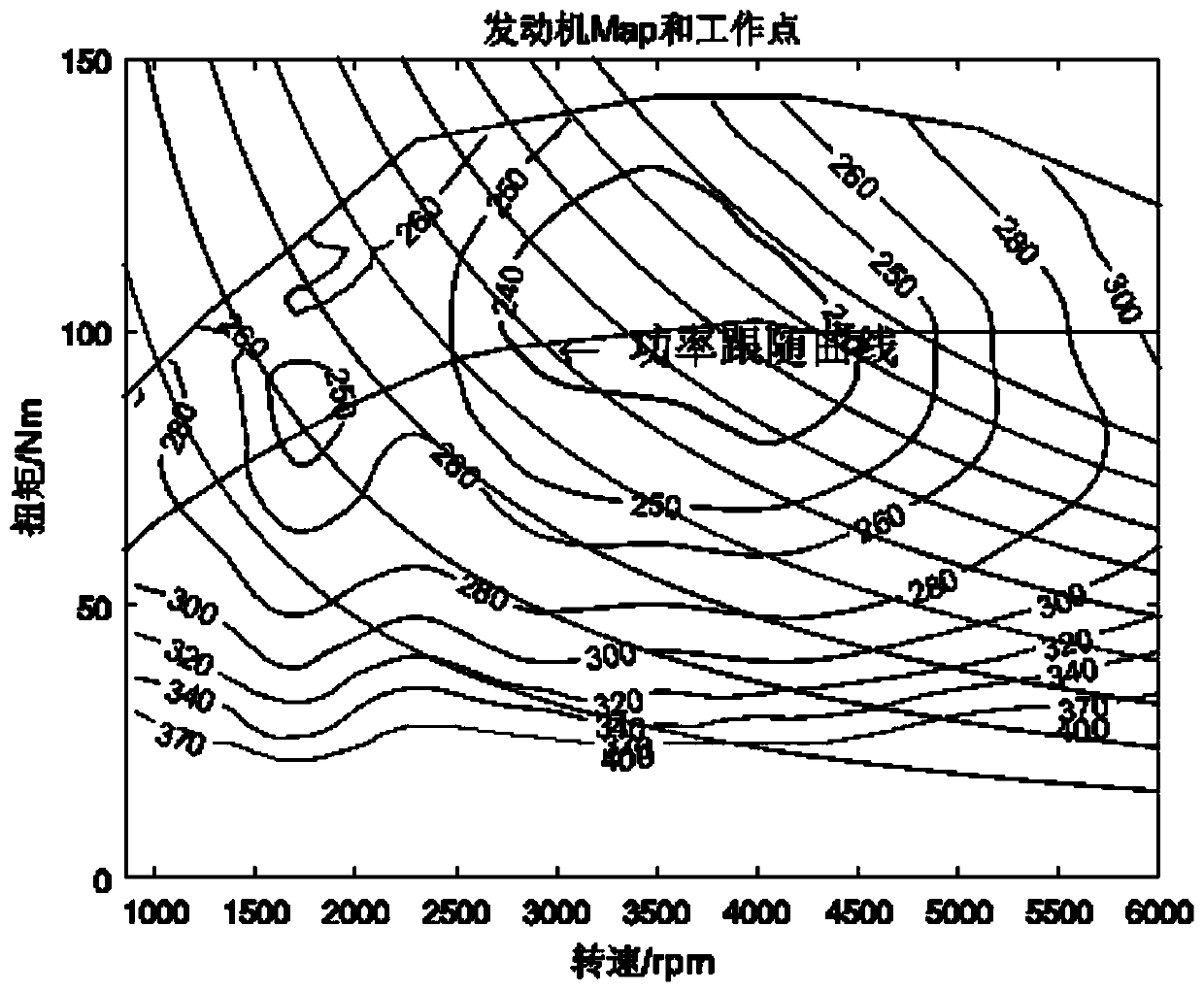

[0049] Determine the fixed speed value of the engine: if image 3 As shown, obtain the external characteristics and universal characteristic curve of the engine, and the maximum engine speed nmax; calculate the best economic zone of the engine according to the external characteristics and universal characteristic curve, generally the engine speed is between 0.2nmax an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com