Three-rotor spinning fixture and its operation technology for small-diameter plunger assembly

A small-diameter, three-spin wheel technology, applied in the field of spinning fixtures, can solve the problems of flexibility and axial clearance that are difficult to meet parts requirements, product quality consistency is difficult to guarantee, and parts size requirements are high, so as to improve poor processing quality. , good clamping effect and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the content of the present invention easier to understand, the content of the present invention will be described in detail below in conjunction with the accompanying drawings.

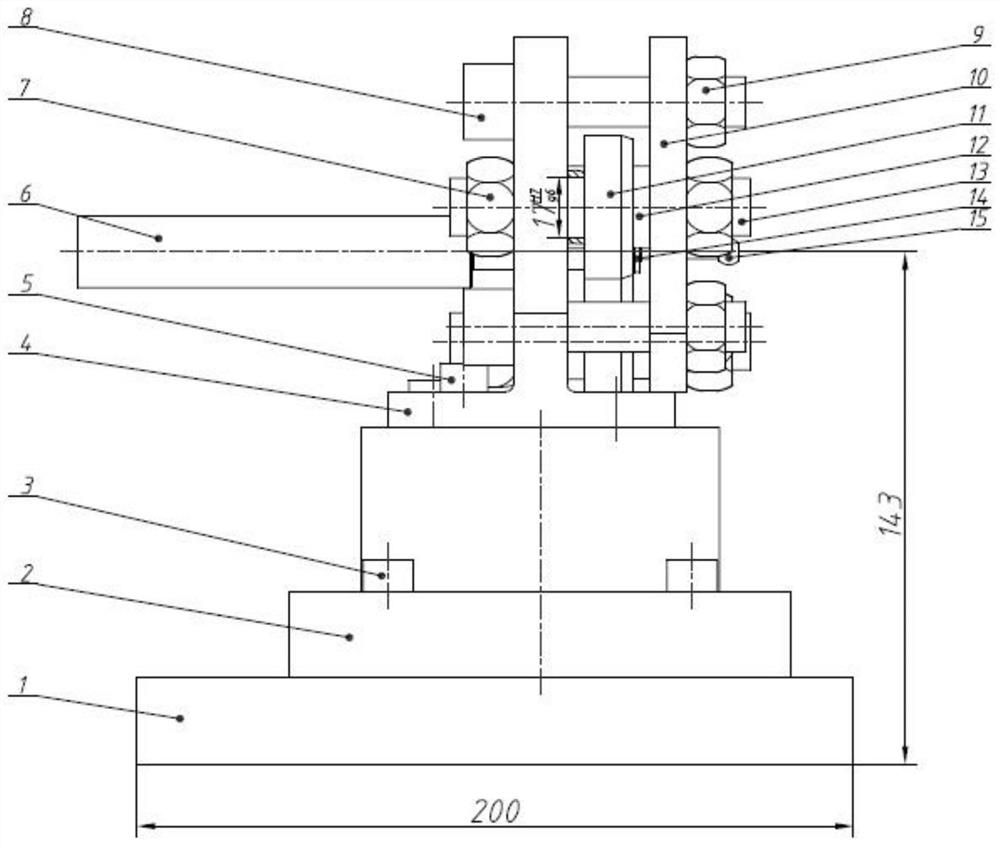

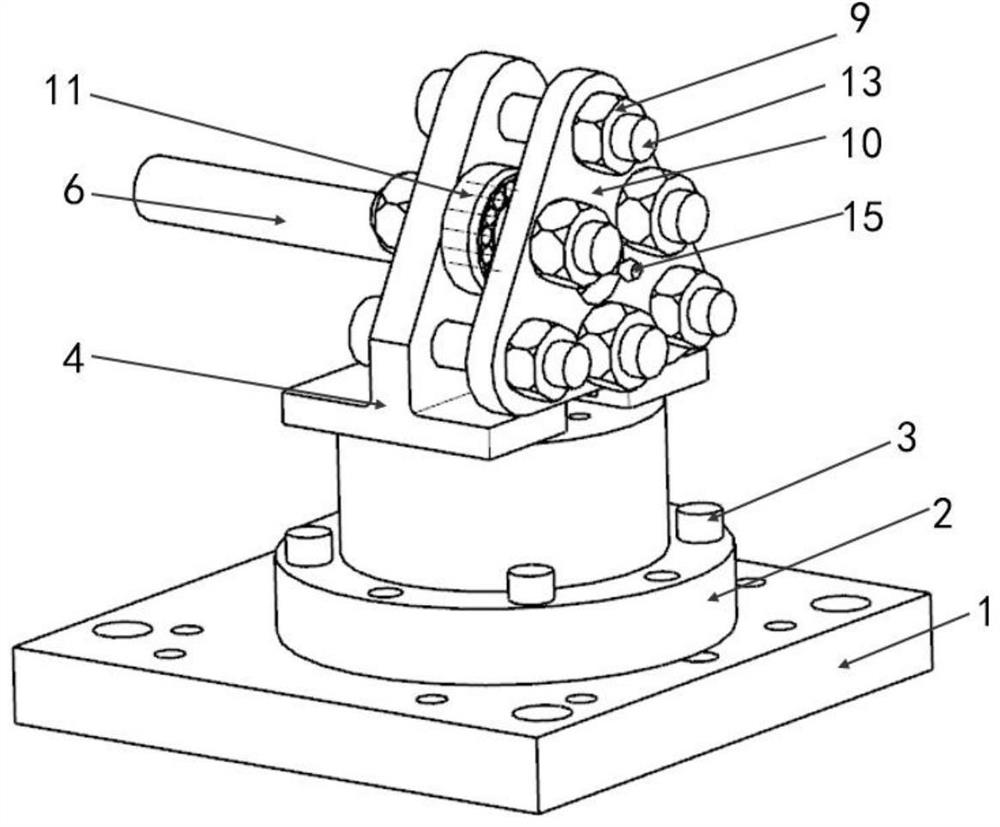

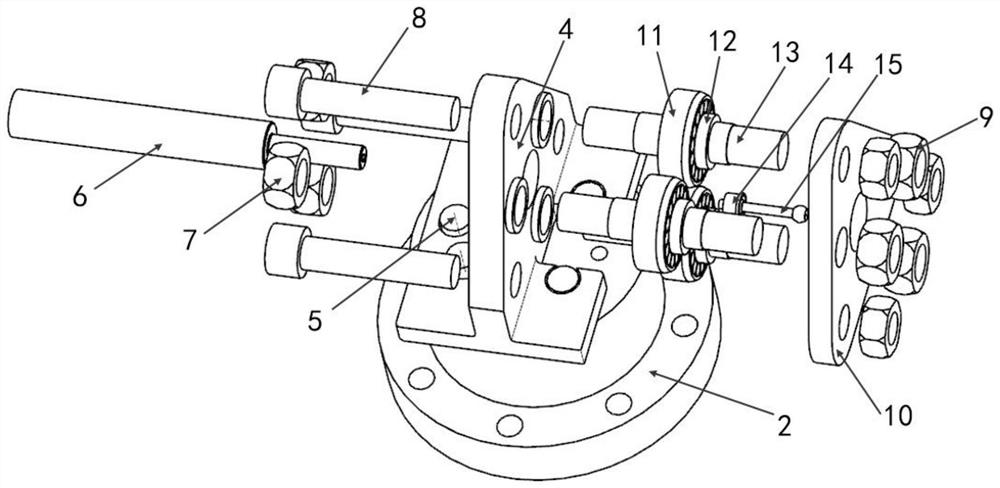

[0036] see figure 1 , figure 2 and image 3 , a three-wheel spinning closing fixture suitable for small-diameter plunger assemblies, used for spinning forming and spinning force measurement of small oil pump plunger assemblies. Including: wheel frame 4, wheel frame cover plate 10, wheel shaft 13, bushing 12, wheel 11, collet 6, dynamometer 2 and machine adapter plate 1. There are threaded holes on the machine adapter plate 1, which are connected and fixed with the dynamometer 2 by bolts, and corresponding countersunk holes are opened to connect and fix with the machine slide table, so as to realize accurate measurement of the spinning force during the spinning process.

[0037] The wheel shaft 13 is a stud bolt with threads at both ends and the optical axis in the middle. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com