Gas-lubricated slide ring seal with improved Anti-fouling protection

A mechanical seal and mechanical seal technology are applied to the sealing of engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., which can solve the problems of reducing the life of mechanical seals, achieve improved antifouling, and significantly Effects of safe operation and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

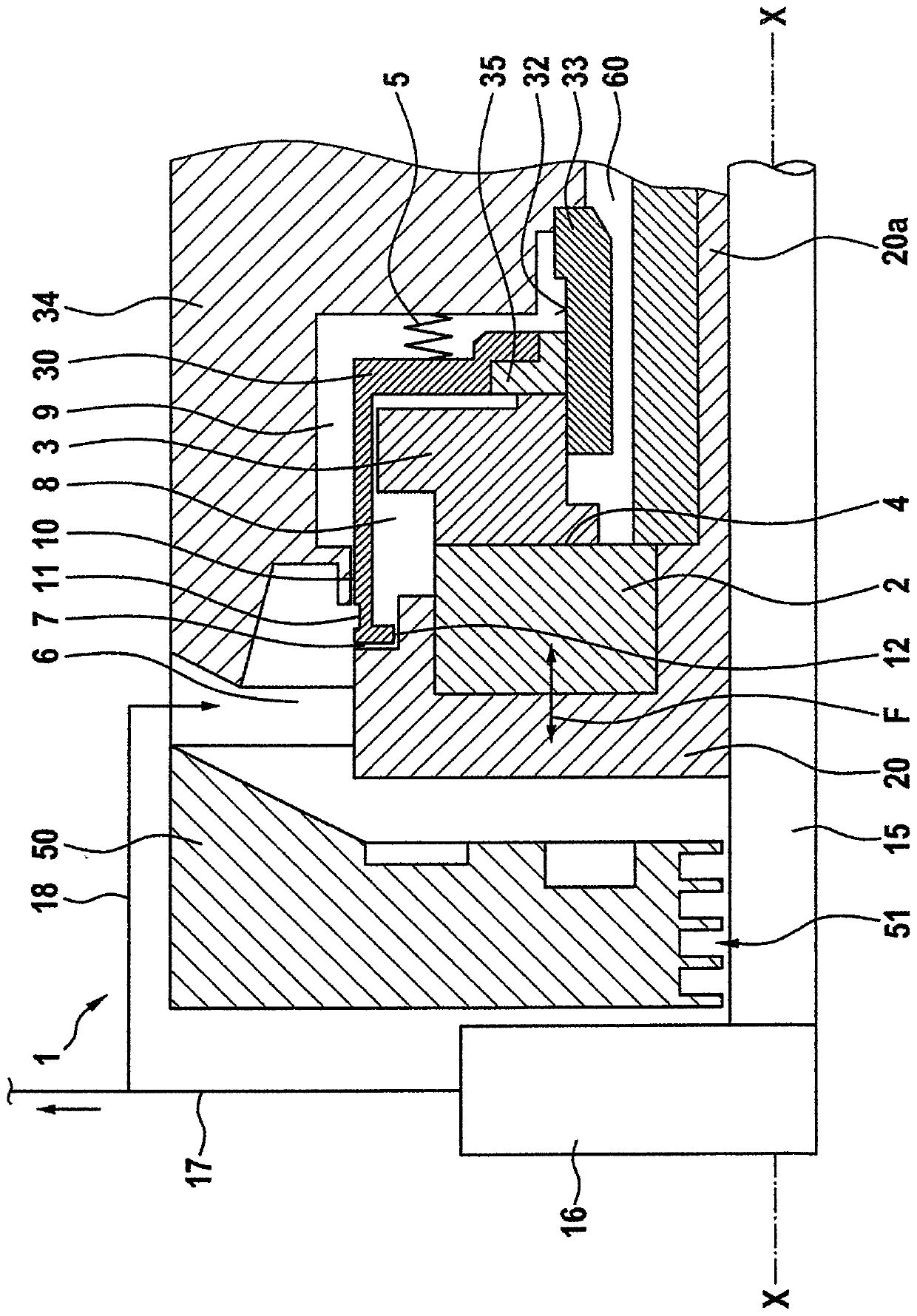

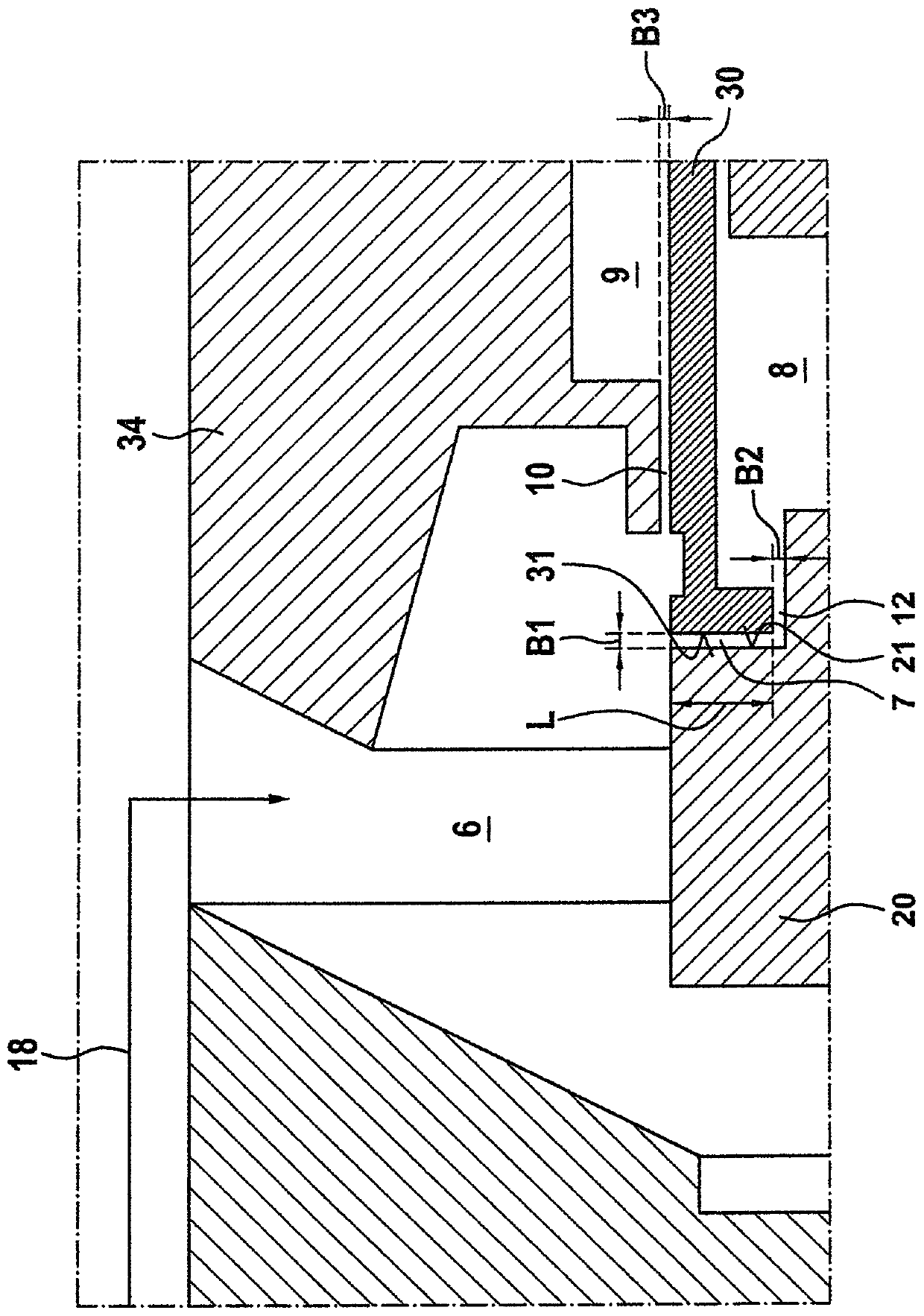

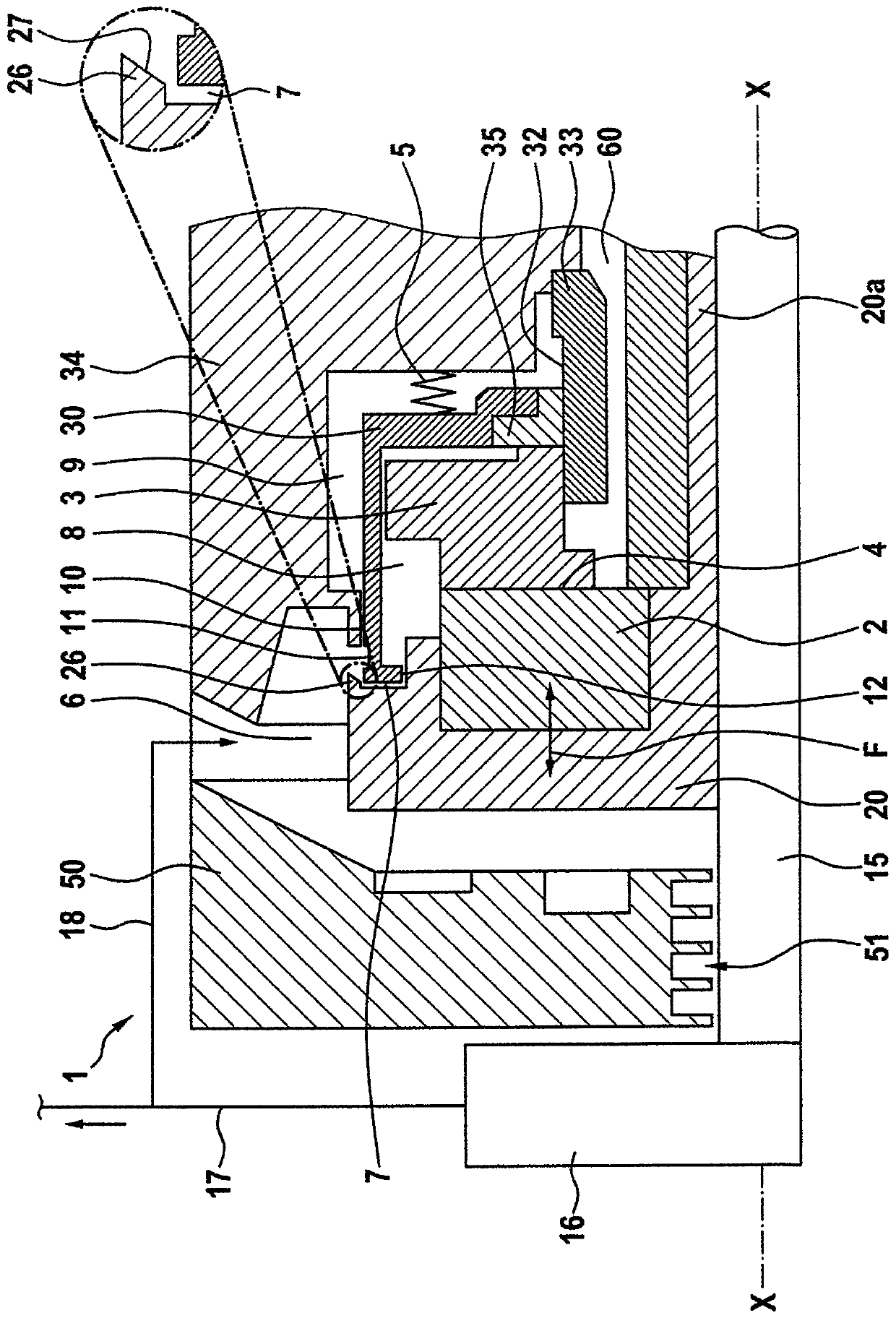

[0022] Now refer to figure 1 and figure 2 , the mechanical seal arrangement 1 according to the first preferred embodiment of the present invention will be described in detail below. The mechanical seal arrangement 1 seals the fluid chamber 6 against the atmosphere 60 .

[0023] From figure 1 As can be seen in the figure, the mechanical seal 1 is arranged on the rotating shaft 15 and seals the compressor 16 . The compressor compresses the gaseous fluid supplied to the user via discharge line 17 . A branch line 18 branches off from the discharge line 17 and leads to the fluid chamber 6 at the mechanical seal arrangement 1 .

[0024] The mechanical seal arrangement 1 includes a mechanical seal including a rotary slip ring 2 and a stationary slip ring 3 , and a sealing gap 4 is defined between the rotary slip ring 2 and the stationary slip ring 3 .

[0025] The mechanical seal seals the fluid chamber 6 against the atmosphere 60 .

[0026] The rotary mechanical seal 2 is hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com