A chain grate machine with adjustable axial clearance

A technology of axial clearance and chain grate machine, which is applied in the field of chain grate machines with adjustable axial clearance, which can solve the problems of reduced output of finished balls, increased production costs, leakage, etc., and achieve the effect that the connection is not easy to fall off and the connection is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

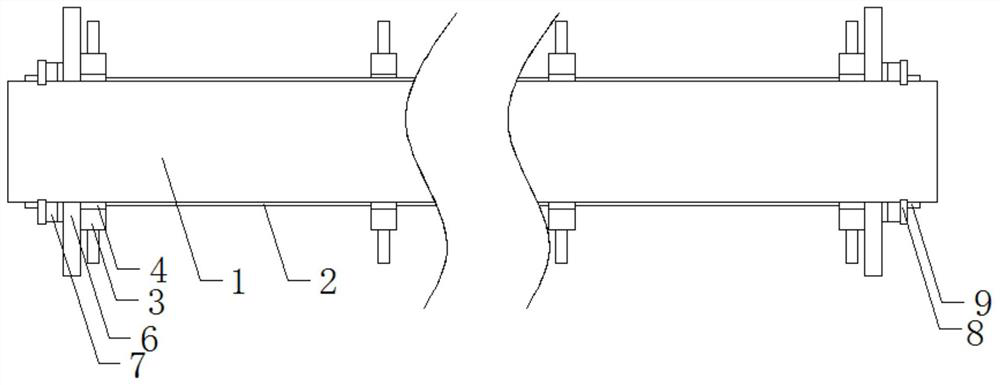

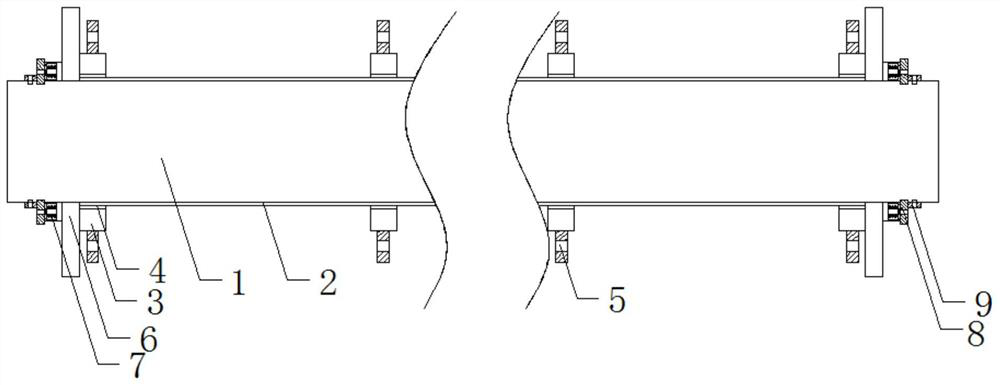

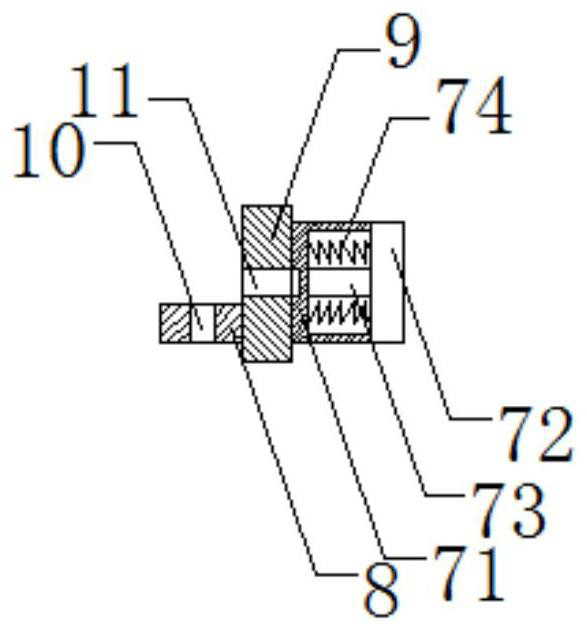

[0022] see Figure 1-3 , the present invention provides a technical solution: a chain grate machine with adjustable axial clearance, including a small shaft 1, the top and bottom of the small shaft 1 are welded with spacer tubes 2, and the spacer tubes 2 are used to keep each chain The distance between the joints 3, the end of the distance tube 2 away from the small shaft 1 is sleeved with a chain link inner sleeve 4, and the end of the chain link inner sleeve 4 far away from the small shaft 1 is integrally formed with a chain link 3, and the body of the chain link 3 There is a first screw hole 5 in the horizontal direction, and the chain link 3 can cooperate with the spacer pipe 2 to connect the grate plate through the first screw hole 5 to connect the screw, so as to increase the stability of the grate plate connection.

[0023] The ends of the left and right side chain links 3 that are far away from each other are connected with a side plate 6 by screws, and the front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com