System for deoiling an air-oil mixture for pressurising seals of a turbine engine

A turbine engine, pressurized air technology, applied in the direction of engine components, engine lubrication, engine function, etc., can solve problems such as reducing turbine engine maintenance operations, and achieve the effect of long mission duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

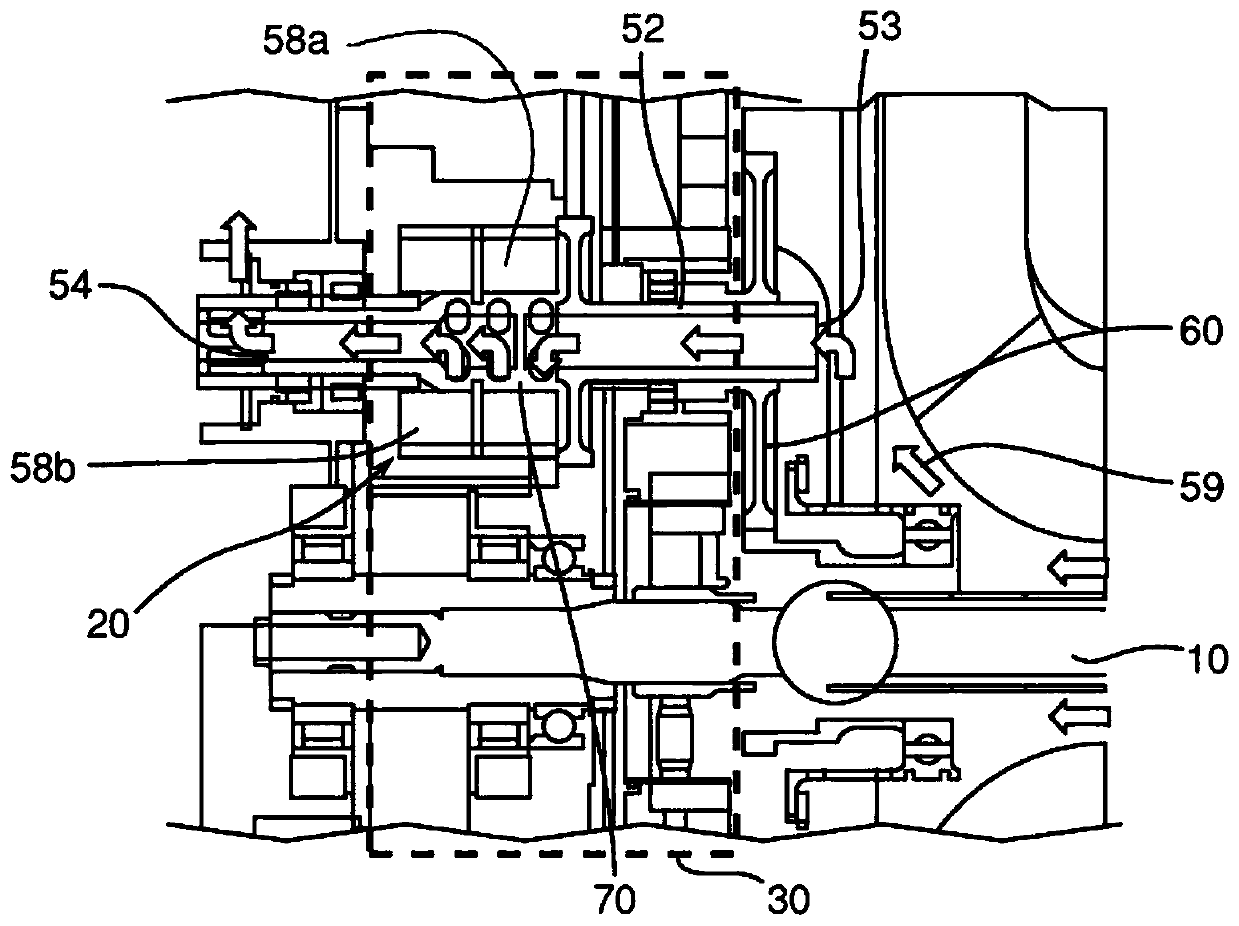

[0040] In the drawings, for purposes of clarity and illustration, scale and dimensions have not been strictly adhered to.

[0041] For different elements of an oil removal system having the same function or of similar nature, the same reference numerals are used in the different figures.

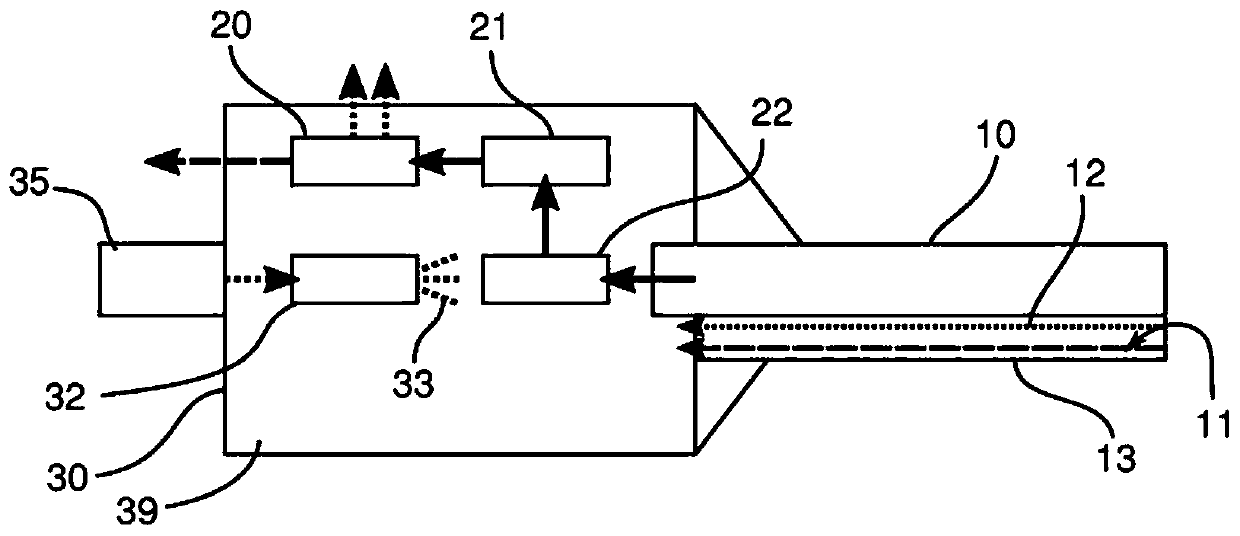

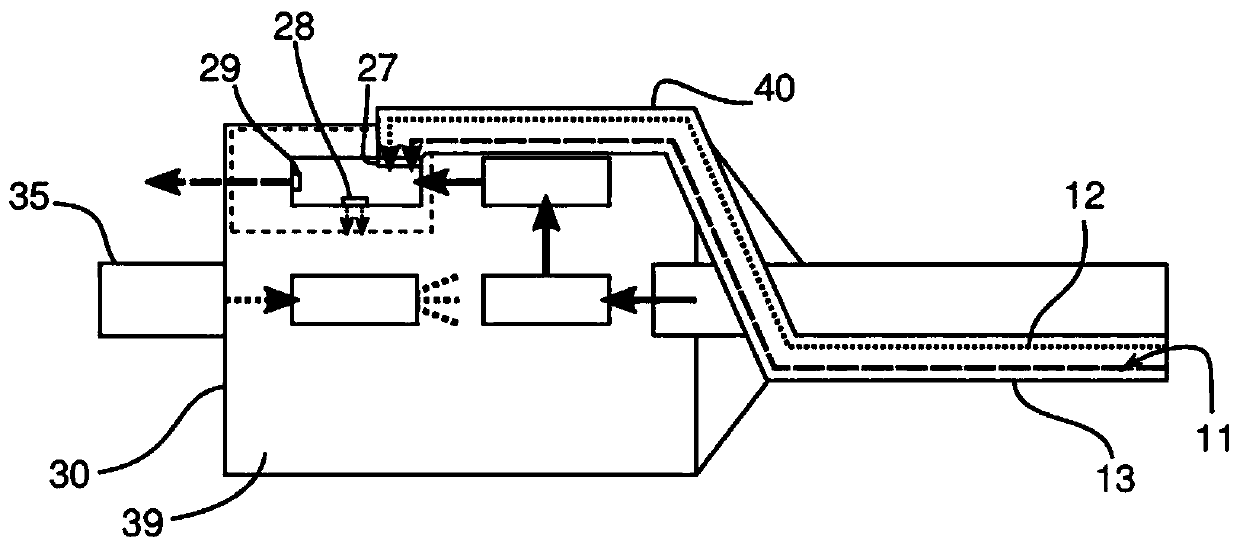

[0042] figure 1 Shown is a drive shaft 10 of a turbine engine equipped with an oil removal system according to the prior art. The drive shaft 10 is, for example, the row of gas generators and shafts of the free turbine of a turbine engine of a helicopter. Pressurized air, indicated by the solid arrow 11, is injected into the seal to ensure the sealing of the pressurized casing 13 of the turbine engine. Then, as the air 11 circulates within the pressurized housing 13, the air 11 is charged into the oil. exist figure 1In , the air and oil mixture circulating along the shaft 10 of the turbine engine is shown. Dashed line 11 represents air and dashed line 12 represents oil of the mixture. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com