High-voltage breaker spring operating mechanism and transmission device

A high-voltage circuit breaker and operating mechanism technology, which is applied to the power device inside the switch, the protection switch operation/release mechanism, and the status indicator of the switchgear, etc. Observation inconvenience and other problems, to achieve the effect of highlighting substantive features, convenient observation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

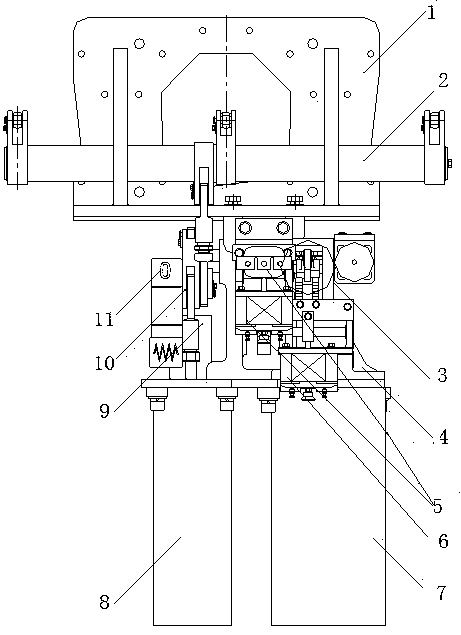

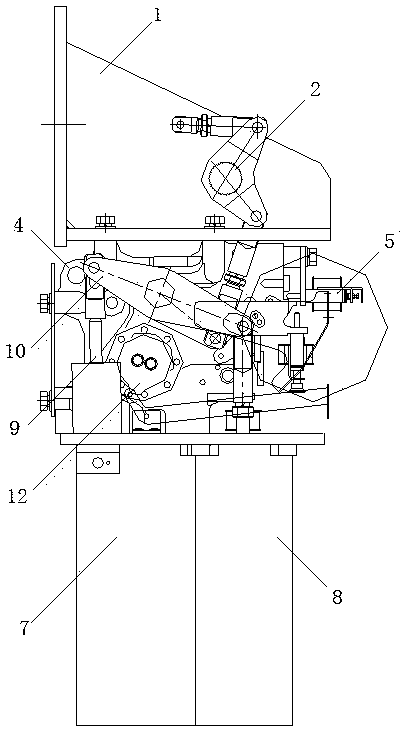

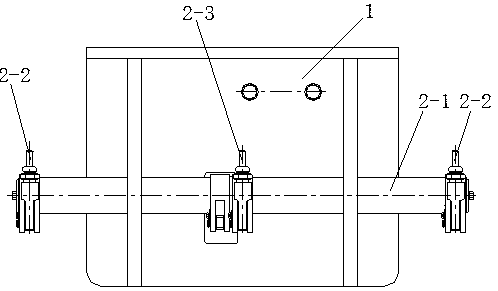

[0028] The invention provides a high-voltage circuit breaker spring operating mechanism and transmission device, including a mechanism bracket 4, the mechanism bracket 4 is cast with high-strength cast aluminum, and is processed by a horizontal machining center. The unit assembly is divided into three chambers distributed , the middle part of the mechanism support 4 is provided with an energy conversion assembly 10 and an opening control assembly 5, and the right side of the mechanism support 4 is provided with an energy storage assembly 3, a closing spring assembly 7 and a closing control assembly 6. 4 The opening spring assembly 8 and buffer 9 are arranged on the left side; when the energy storage assembly 3 moves, it drives the closing spring assembly 7 to realize energy storage; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com