Method for judging inclusion group flaws in flat metal plate by using double-crystal straight probe

A flat metal, straight probe technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as clear instructions, and achieve the effects of improving accuracy, lowering personnel training costs, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

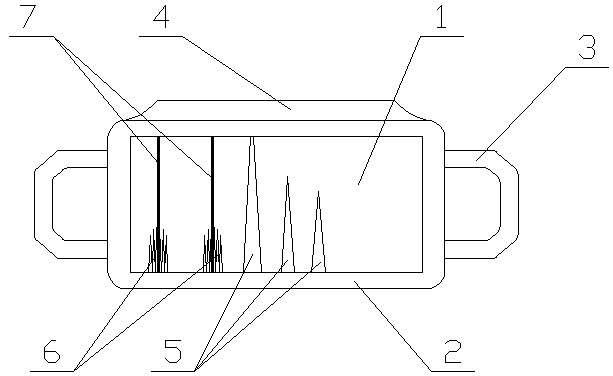

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail:

[0020] A method for judging inclusion group defects in flat metal plates with dual-crystal straight probes, suitable for the detection of internal inclusion groups on flat metal plates with a thickness of more than 6mm by using a type A pulse reflection ultrasonic flaw detector, and also applicable to conventional The 5Pφ20F10 dual-crystal straight probe detects the internal inclusion group on the flat metal plate with a thickness of more than 6mm, including the following steps:

[0021] (1) Choose to use 5Pφ20F10 dual crystal straight probe:

[0022] (2) Choose to use the flaw detector within the verification period to adjust the instrument;

[0023] (3) After finding the defect, adjust the detection sensitivity to see the peak profile of the defect wave;

[0024] (4) When judging whether the waveform satisfies the following conditions, if so, it can be judged that the defect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com