Method for judging delamination flaws of flat metal plate by using ultrasonic single-crystal straight probe

A technology for delamination defects and flat metals, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as no clear white spots and crack identification methods, and achieve simple methods, high efficiency, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use the method described above for flaw detection on the plate. The specific process is as follows:

[0030] 1) Select a single crystal straight probe with a diameter of 20mm and install it on the ultrasonic flaw detector.

[0031] 2) Adjust the ultrasonic flaw detector to ensure that the ultrasonic flaw detector is sensitive and reliable.

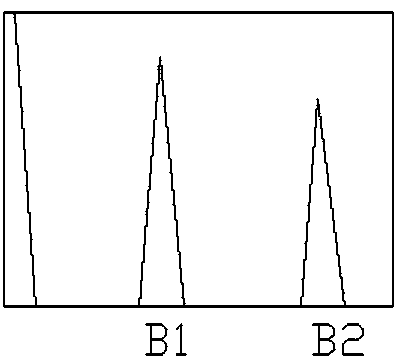

[0032] 3) Adjust the sensitivity of the ultrasonic flaw detector, use a single crystal straight probe to move on the surface of the plate, and observe the waveform on the screen of the ultrasonic flaw detector at the same time, when the defect wave is observed, determine the position as the defect. Then reduce the sensitivity of the ultrasonic flaw detector. At this time, the peaks of the first defect wave F1 and the first bottom wave B1 can be seen. The waveforms of the two waves are independent A-shaped waves, and the waveforms are steep.

[0033] 4) Judging qualitatively, the ratio of the peak heights of the first defect wave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com