Alternating current testing device and method for Seebeck coefficient

A technology for testing devices and coefficients, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of high temperature control requirements, slow measurement speed, poor effect, etc., and achieve the goal of avoiding DC noise The effects of interference, fast response speed, and flexible relative position relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

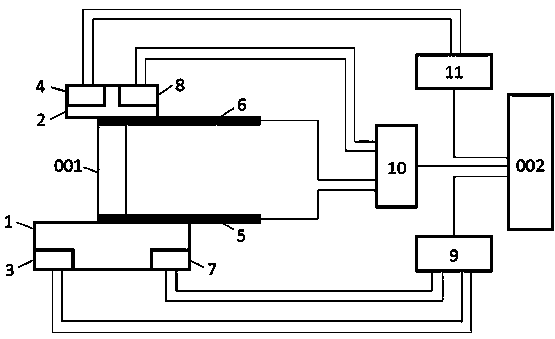

[0046] An AC testing device for Seebeck coefficient, including a sample chamber and a sample table 1, a chuck 2, a main heater 3, a sub heater 4, a main probe 5, a sub probe 6, a main temperature measuring element 7, and a sub temperature measuring Component 8, temperature controller 9, lock-in amplifier 10, AC power meter 11.

[0047] The sample chamber is a space that can be sealed. The sample table 1, the chuck 2, the main heater 3, the auxiliary heater 4, the main probe 5, the auxiliary probe 6, the main temperature measuring element 7, and the auxiliary temperature measuring element 8 are located in the sample chamber, and the temperature controller 9, The lock-in amplifier 10 and the AC power meter 11 are located outside the sample room and connected to a computer 002 respectively.

[0048] The main heater 3, the main probe 5, and the main temperature measuring element 7 are all installed on the sample stage 1, and the main probe 5 can directly contact with the sample 0...

Embodiment 2

[0065] In this embodiment, on the basis of Embodiment 1, the main temperature measuring element 7 and the auxiliary temperature measuring element 8 in the AC testing device are further limited.

[0066] Both the main temperature measuring element 7 and the auxiliary temperature measuring element 8 are resistance thermometers. Alternatively, both the main temperature measuring element 7 and the auxiliary temperature measuring element 8 are thermocouples. Resistance thermometers and thermocouples are mature existing products. The improvement of this embodiment does not lie in the improvement of resistance thermometers or thermocouple structures. Only resistance thermometers or thermocouples are used for temperature measurement, and resistance thermometers or thermocouples are used for temperature measurement. Prior art, so its structure or working principle will not be described in detail.

[0067] Other parts of this embodiment are the same as those of Embodiment 1, so details...

Embodiment 3

[0069] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the working environment of the sample chamber is further limited.

[0070] The working environment of the sample chamber is a vacuum environment, that is, the main probe 5, the auxiliary probe 6, and the sample 001 are all in a vacuum environment during the test. Alternatively, the working environment of the sample chamber is a protective gas environment, that is, the main probe 5 , the auxiliary probe 6 , and the sample 001 are all in a protective gas environment during the test.

[0071] When the AC measuring device measures the Seebeck coefficient of the sample 001, the main heater 3 heats the sample stage 1 to provide the required ambient temperature; in order to prevent the sample 001 from being oxidized, the sample chamber can be evacuated or filled with protective gas. The shielding gas in the present invention can be a commonly used shielding gas, such as nitrogen, argon or a mixture thereof.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com