Method for predicting tensile strength of woven ceramic-based composite material

A composite material and prediction method technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large difference in actual strength and unsatisfactory prediction results, and achieve accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

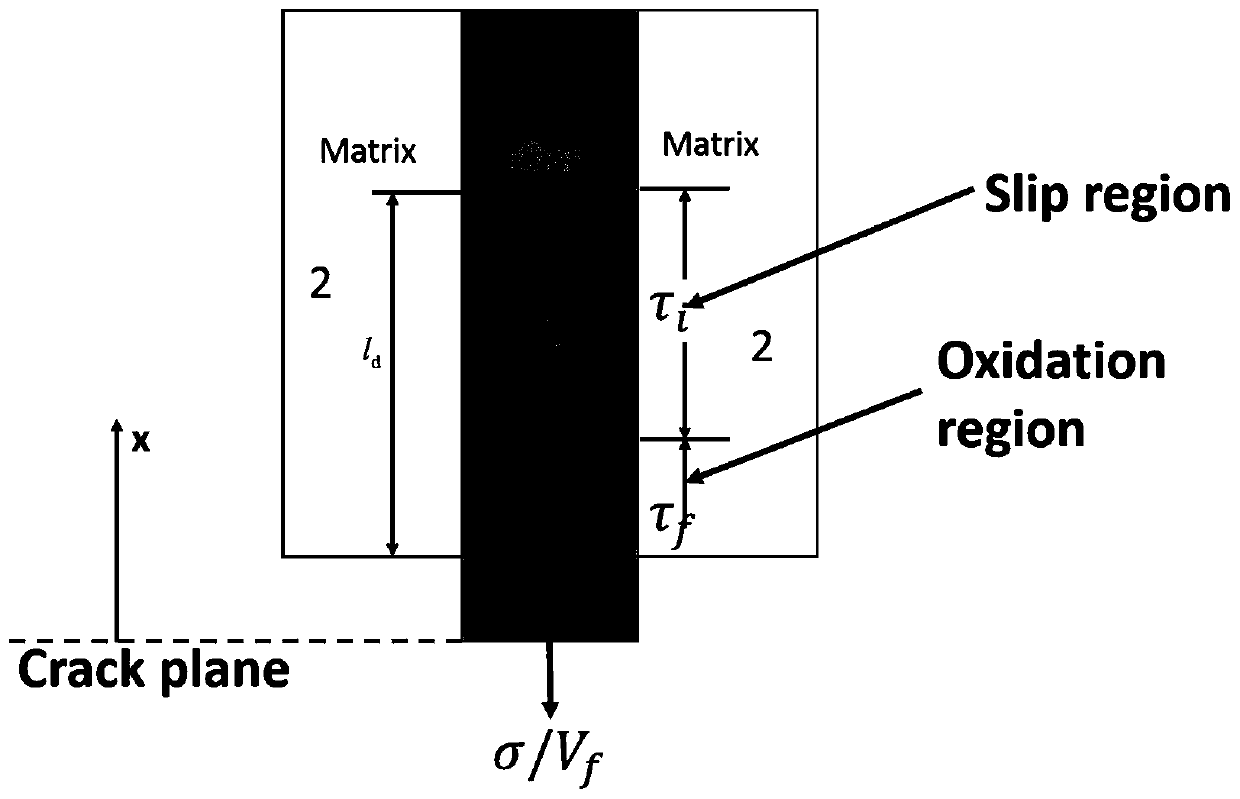

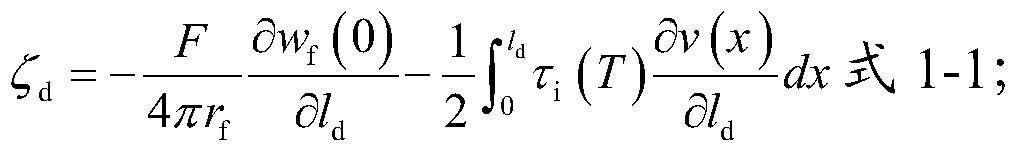

Method used

Image

Examples

Embodiment 1

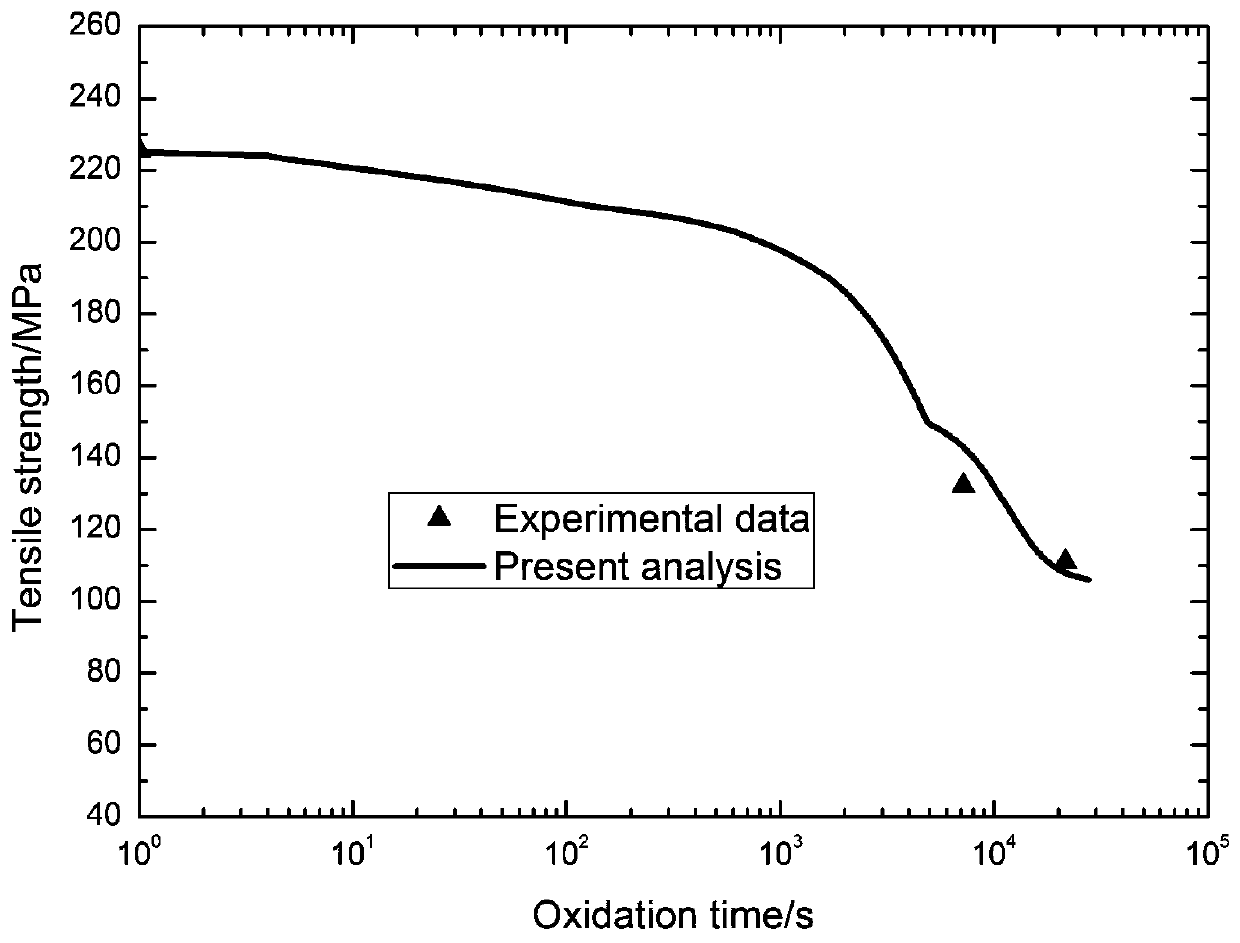

[0177] Taking the 2D C / SiC braided ceramic matrix composite material as the test sample, test the tensile strength of the sample in a high temperature environment of 700°C under different oxidation times, and draw the test curve of the relationship between the tensile strength of the test sample and the oxidation time;

[0178] Predict the tensile strength of the test sample using the following parameters: V f = 40%, E f =200GPa, E m =350GPa, r f = 3.5 μm, ζ d =1.2J / m 2 , τ 0_i =6MPa,τ 0_f =1MPa, α rf =7×10 -6 / °C, α lf =1×10 -6 / °C,α rm = α lm =4.8×10 -6 / °C, ΔT=-1000°C, m f =5.

[0179] Substituting the above parameters into the established matrix crack plane load bearing relationship equation, the simulation curve of the relationship between the tensile strength and oxidation time of the ceramic matrix composite material is obtained, as shown in figure 2 shown. Depend on figure 2 It can be seen that the degree of coincidence between the simulation curve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com