Modular cascade heating scale heating air energy station system

A modular, energy station technology, applied in hot air central heating systems, heating systems, household heating, etc., can solve the problems of air source heat pump heating capacity attenuation, unusable, limited application environment temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

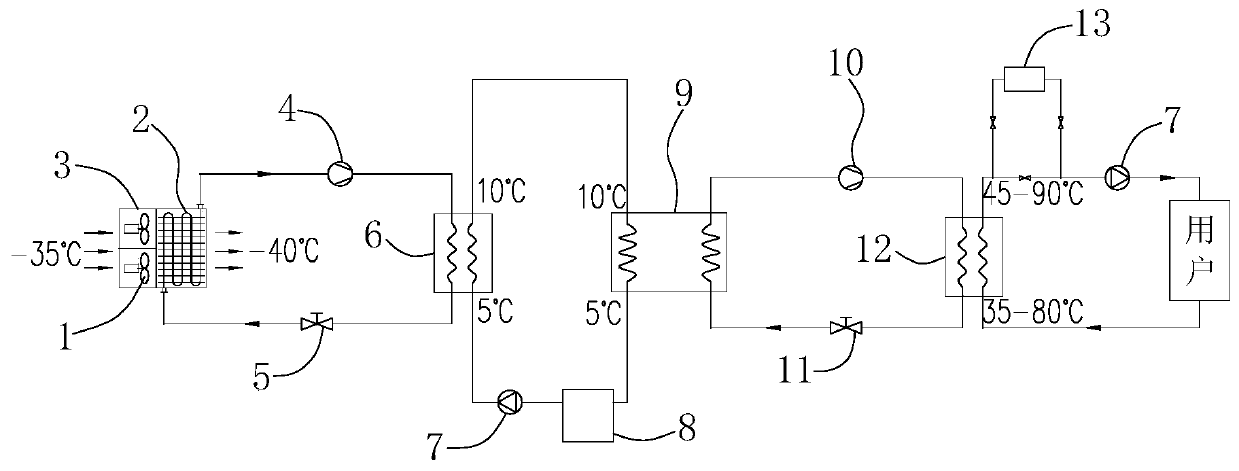

[0042] Such as figure 1 As shown, the number of primary condenser 6, secondary evaporator 9 and secondary condenser 12 in the modularized cascade heating scale heating air energy station system of the present invention is set to one. At this time, the primary heating system has only one primary heating module, and the primary heating module has only one primary heating unit, that is, one primary heating unit forms a primary heating module. The secondary heating system also has only one secondary heating module, and the secondary heating module has only one secondary heating unit, that is, one secondary heating unit forms a secondary heating module.

Embodiment 2

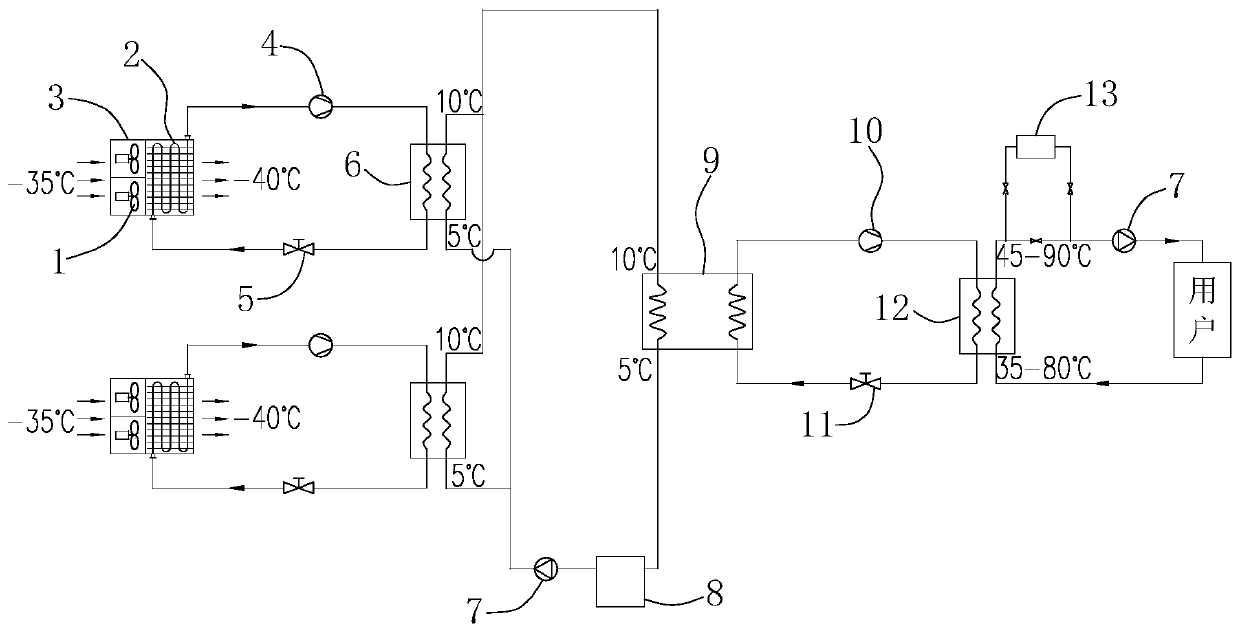

[0044] Such as figure 2 As shown, the number of primary condensers 6 in the modularized cascade heating scale heating air energy station system of the present invention is set to two, and the number of secondary evaporators 9 and 12 are both set to one. Two of the primary condensers 6 are arranged in parallel.

[0045] In this embodiment, the primary heat raising system may be composed of one primary heat raising module, or may be composed of two primary heat raising modules. When the primary heating system is composed of a primary heating module, then the primary heating module is composed of two primary heating units; when the primary heating system is composed of two primary heating modules, then The first-level heating module is composed of one first-level heating unit.

[0046] The secondary heating system has only one secondary heating module, and the secondary heating module has only one secondary heating unit, that is, one secondary heating unit forms a secondary he...

Embodiment 3

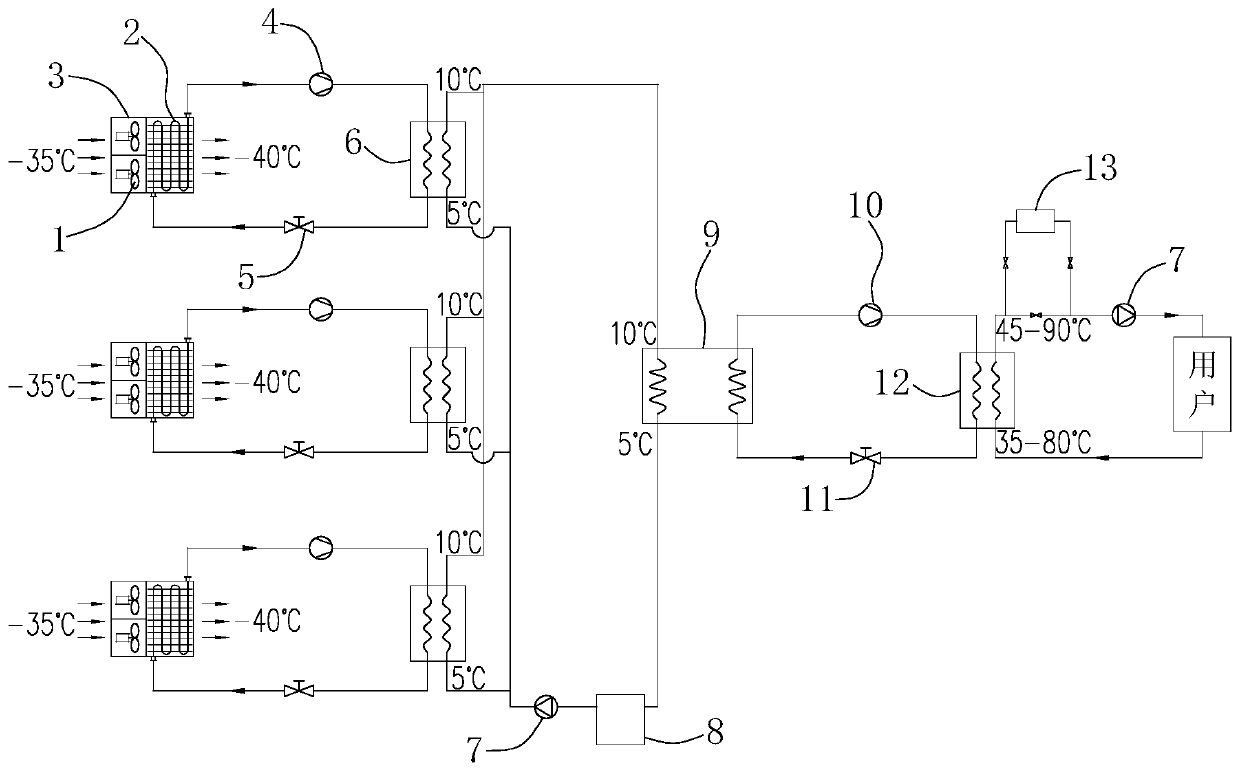

[0048] Such as image 3 As shown, the number of primary condensers 6 in the modularized cascade heating scale heating air energy station system of the present invention is set to three, and the number of secondary evaporators 9 and secondary condensers 12 is set to one . Three of the primary condensers 6 are arranged in parallel.

[0049] In this embodiment, the primary heat raising system may consist of one, two or three primary heat raising modules. When the primary heating system consists of one primary heating module, then the primary heating module consists of three primary heating units. When the primary heating system is composed of two primary heating modules, one of the primary heating modules is composed of two primary heating units, and the other primary heating module is composed of a primary heating unit . When the first-level heat-raising module is composed of three first-level heat-raising modules, then one first-level heat-raising module is composed of one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com