A construction method of raw bamboo frame steel pipe joints adapting to the change of raw bamboo diameter

A diameter-changing, original bamboo technology, applied in the direction of building types, buildings, building components, etc., can solve the problems of weakening the overall strength, affecting the life of the structure, easy deformation, etc., and achieve the effects of improving construction efficiency, improving seismic performance, and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

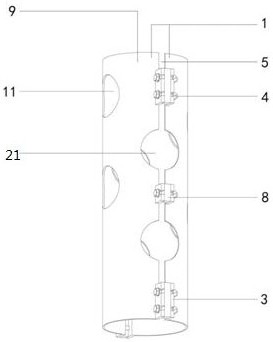

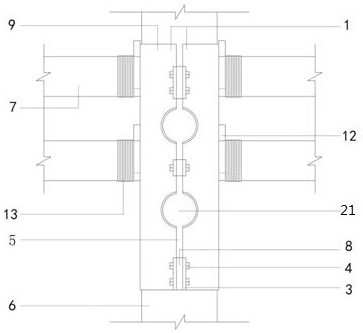

[0025] An original bamboo frame steel pipe structure adapted to the change of original bamboo diameter, such as figure 1 As shown, it is used in the case where the difference in the original bamboo specifications is small, the upper load is small, and the seismic fortification intensity is low, including the vertical steel casing 1, which includes two semicircular vertical steel casings. Sleeve assembly 9, two semi-circular vertical steel casing assemblies 9 are provided with a plurality of opposite wing plates I3 respectively, rubber gasket I8 is arranged between the opposite wing plates I3, and threaded threads are provided on the wing plates I3 Hole I14, bolt I4 passes through threaded hole I14 to connect two semicircular vertical steel casing components 9; there are two opposite holes I11 on the semicircular vertical steel casing components 9, two and a half The connection of the circular vertical steel sleeve assembly 9 forms a notch I5 and a plurality of holes II21. In t...

Embodiment 2

[0028] An original bamboo frame steel pipe structure adapted to the change of original bamboo diameter, such as image 3 As shown, it is used in the case of small difference in raw bamboo specifications, small upper load, and low seismic fortification intensity areas, including vertical steel casing 1, 2 sets of parallel wing tubes I2, and each set of parallel wing tubes I2 There are two respectively, the vertical steel casing 1 includes two semicircular vertical steel casing assemblies 9, and the two semicircular vertical steel casing assemblies 9 are respectively equipped with 3 opposite wing plates I3, opposite to each other. There is a rubber gasket I8 between the wing plates I3, and there is a threaded hole I14 on the wing plate I3, and the bolt I4 passes through the threaded hole I14 to connect two semicircular vertical steel casing components 9; the semicircular vertical There are also two groups of holes I11 on the steel sleeve assembly 9, two for each group, notch I5 ...

Embodiment 3

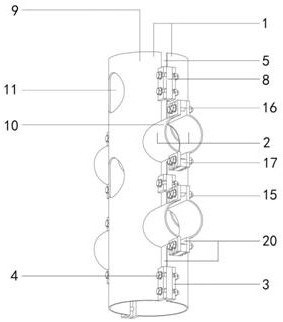

[0031] An original bamboo frame steel pipe structure adapted to the change of original bamboo diameter, such as Figure 4As shown, in the case of areas with large differences in raw bamboo specifications, large upper loads, and high seismic fortification intensity, including vertical steel casing 1, 2 sets of parallel wing tubes I2, and 2 sets of parallel wing tubes II19, each A set of wing tubes I2 parallel to each other has two wing tubes I2, and each set of wing tubes II19 parallel to each other has two wing tubes II19, and the vertical steel casing 1 includes two semicircular vertical steel casing assemblies 9, two Each semicircular vertical steel casing assembly 9 has three opposite wing plates I3 respectively, rubber gasket I8 is arranged between the opposite wing plates I3, threaded holes I14 are provided on the wing plates I3, and bolts I4 pass through Two semicircular vertical steel sleeve components 9 are connected through the threaded hole I14; there are two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com