A construction method for integral sliding of pier wall with connecting beam

A construction method and technology of connecting beams, applied in sea area engineering, water conservancy engineering, sustainable manufacturing/processing, etc., can solve problems such as complex structure and complex construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

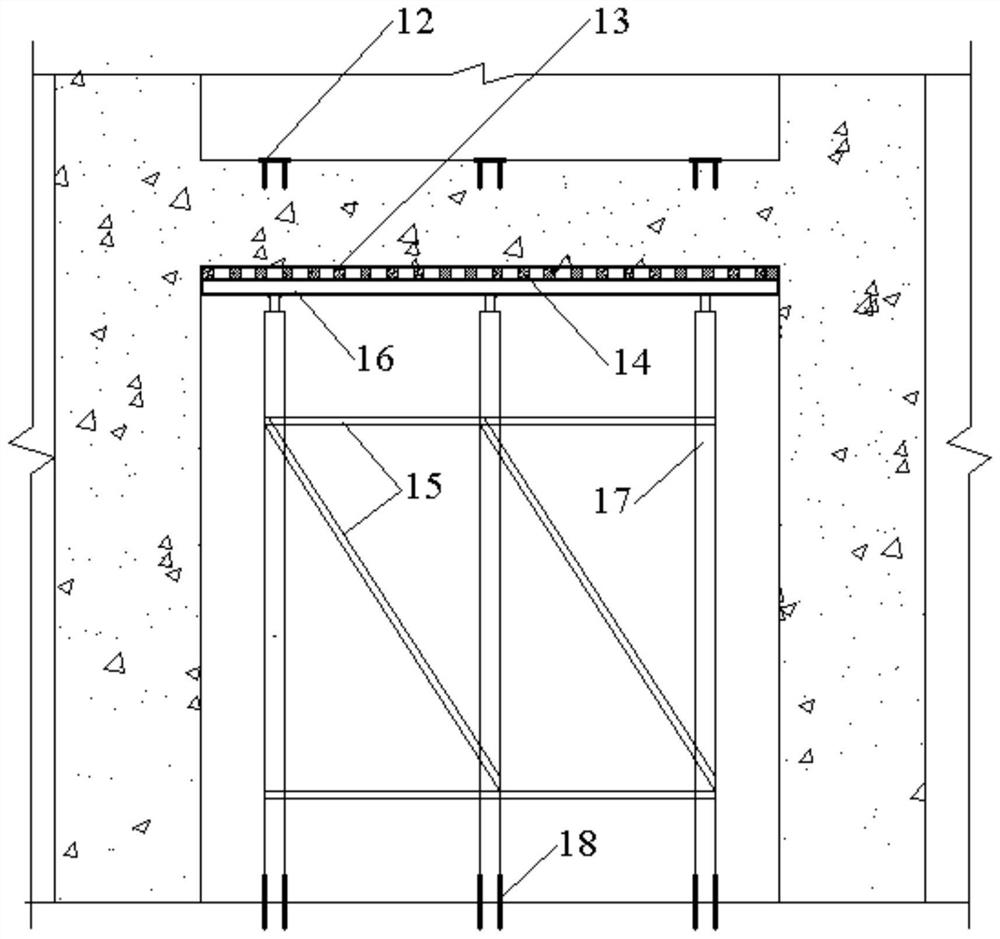

[0031] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

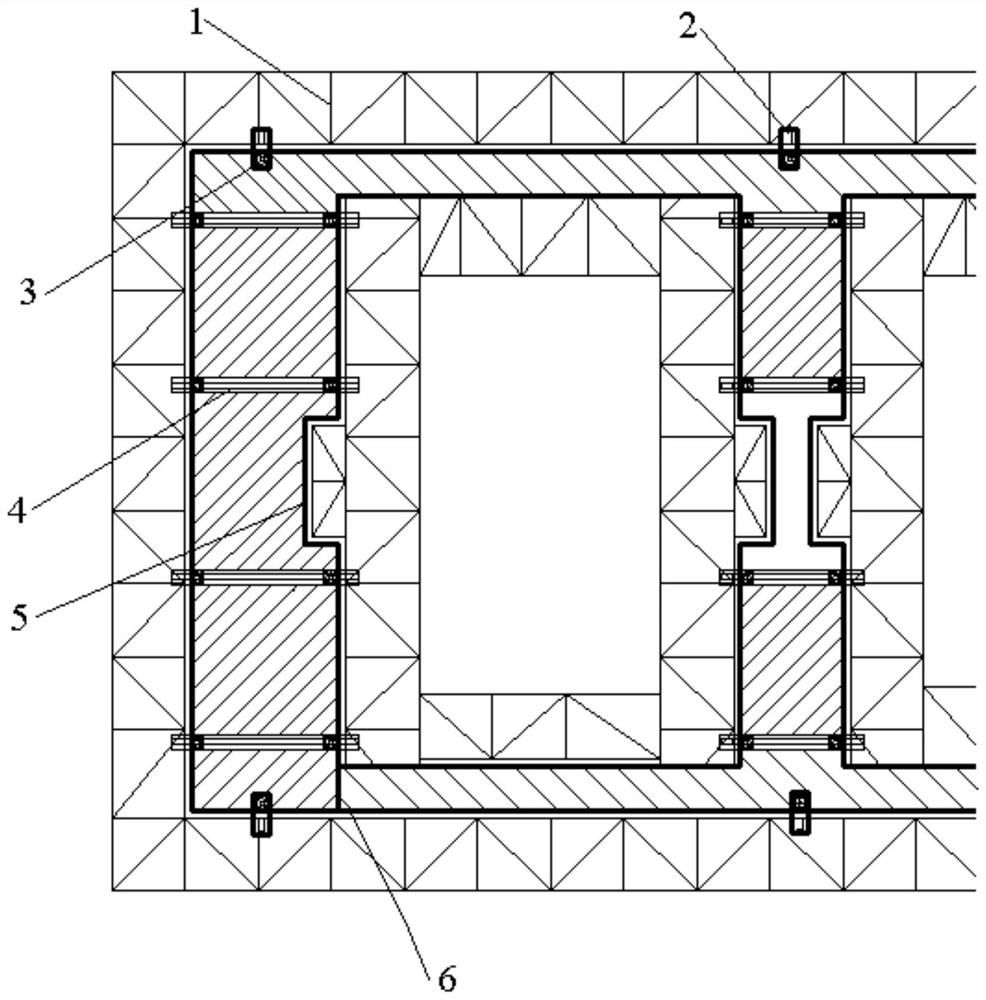

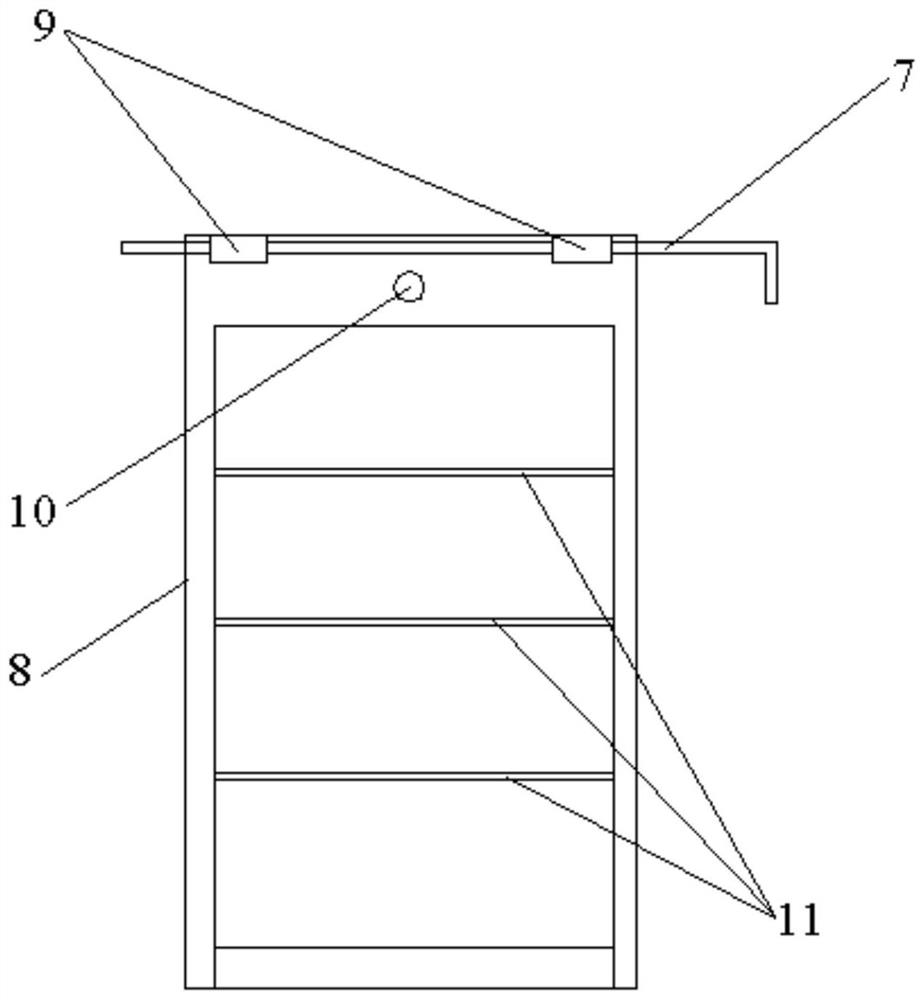

[0032] Such as Figure 1 ~ Figure 3 As shown, the construction method of the integral sliding of the pier wall belt connection beam of the present invention specifically comprises the following steps:

[0033] Step 1. Modify the sliding form device:

[0034] Step 1.1. Set the movable formwork at the junction of the connecting beam and the pier wall as the pier wall sliding formwork, use angle steel welding to make a cuboid truss, and use steel plate embedded welding to make the formwork plate surface of the sliding formwork;

[0035] Step 1.2. Set several hydraulic jacks on the cuboid truss according to the construction specification and building structure, and use channel steel to make several "open" and "F" shaped supports;

[0036] Step 1.3. Install "open" and "F"-shaped brackets on each hydraulic jack, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com