Novel fermentation vinegar production process of liquid kombucha

A new type of kombucha fungus technology, which is applied in the field of liquid kombucha new-type fermentation vinegar production process, can solve the problems of large product quality differences, difficult control of fermentation product quality under fermentation conditions, and difficult industrial production, etc., to achieve stable quality and high product quality. The effect of good quality and easy control of production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

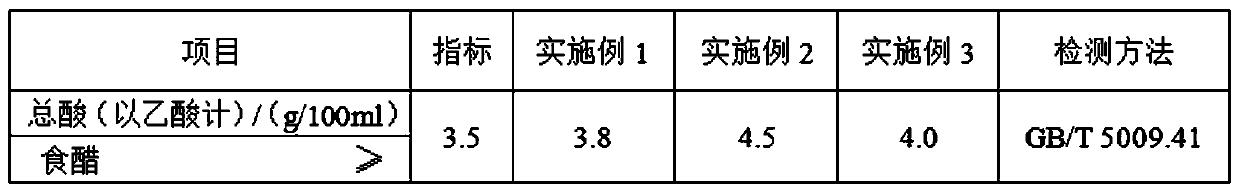

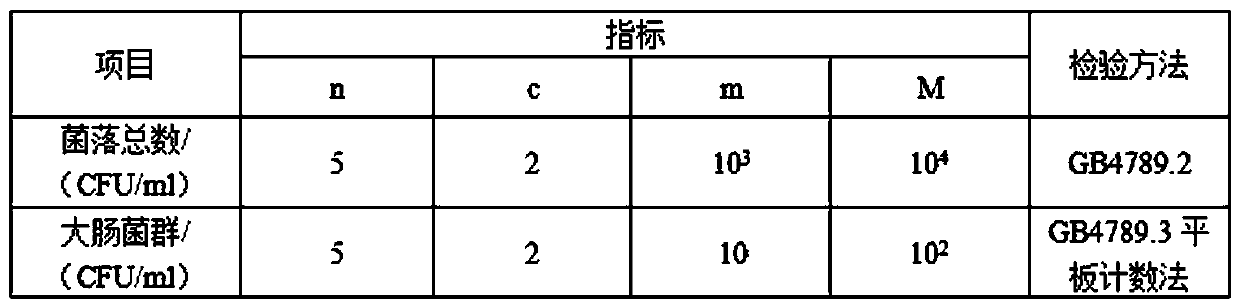

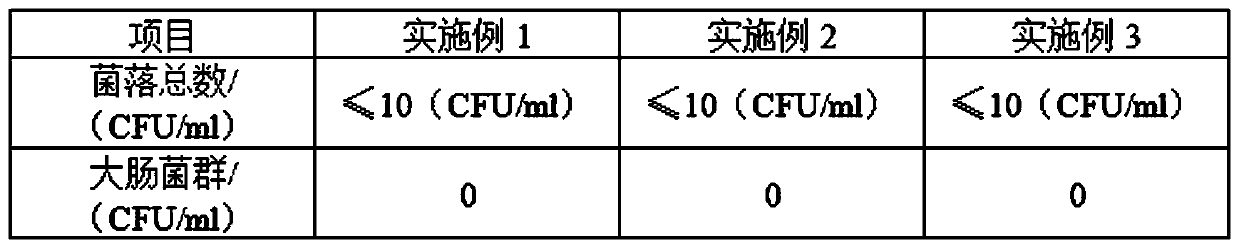

Examples

Embodiment 1

[0033] The present embodiment provides a kind of liquid kombucha new-type fermented vinegar production process, comprises the following steps:

[0034] S1. Prepare materials: select raw materials as 50kg of corn, 20kg of bran, and 25kg of rice bran, remove impurities, pulverize them with a pulverizer, pour them into a steamer for cooking, cook until steamed for 20 minutes, spread out, let cool, and set aside;

[0035] S2. Sterilization: Select 5L 304 stainless steel strain tank and 300L 304 stainless steel fermentation tank, as well as food-grade pipeline valves and air filters. The above equipment is sterilized by 0.1MPa steam for 30min;

[0036] S3, put the raw materials in step s1 into the fermenter in step s2, then add 1% sugar and 2 times the sterilized purified water, and stir evenly;

[0037] S4. Inoculation: inoculate the cultured kombucha into the fermenter, the inoculation amount is 5% of the raw material, and the inoculation temperature is 25°C;

[0038]S5. Kombuch...

Embodiment 2

[0043] The present embodiment provides a kind of liquid kombucha new-type fermented vinegar production process, comprises the following steps:

[0044] S1. Material preparation: select the raw materials as 50kg of corn, 30kg of bran, 25kg of rice bran and 1L of apple juice, remove impurities, pulverize them with a grinder, pour them into a steamer and cook until steamed for 15 minutes, spread out and let cool ,spare;

[0045] S2. Sterilization: Select 5L 304 stainless steel strain tank and 300L 304 stainless steel fermentation tank, as well as food-grade pipeline valves and air filters. The above equipment is sterilized by 0.1MPa steam for 30min;

[0046] S3, put the raw materials in step s1 into the fermenter in step s2, then add 5% sugar and 3 times the sterilized pure water, and stir evenly;

[0047] S4. Inoculation: inoculate the cultured kombucha into the fermenter, the inoculation amount is 10% of the raw material, and the inoculation temperature is 30°C;

[0048] S5. ...

Embodiment 3

[0053] The present embodiment provides a kind of liquid kombucha new-type fermented vinegar production process, comprises the following steps:

[0054] S1. Raw material preparation: the selected raw materials are 50 kg of corn, 25 kg of bran, and 25 kg of rice bran, remove impurities, pulverize them with a pulverizer, pour them into a steamer for cooking, cook until steaming for 20 minutes, spread out, let cool, and set aside;

[0055] S2. Sterilization: Select 5L 304 stainless steel strain tank and 300L 304 stainless steel fermentation tank, as well as food-grade pipeline valves and air filters. The above equipment is sterilized by 0.1MPa steam for 30min;

[0056] S3, put the raw materials in step s1 into the fermenter in step s2, then add 3% sugar and 2 times the sterilized purified water, and stir evenly;

[0057] S4, inoculation: Inoculate the cultured kombucha into the fermenter, the inoculation amount is 5% of the raw material, and the inoculation temperature is 27°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com