An aircraft auxiliary power generation mechanism based on metal nanopowder combustion

A metal nanotechnology, auxiliary power generation technology, applied in the direction of machine/engine, engine components, engine ignition, etc., can solve the problems of aircraft instability, change the aerodynamic shape of the aircraft, flight instability, etc., to achieve easy response, ensure stability, and fully effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

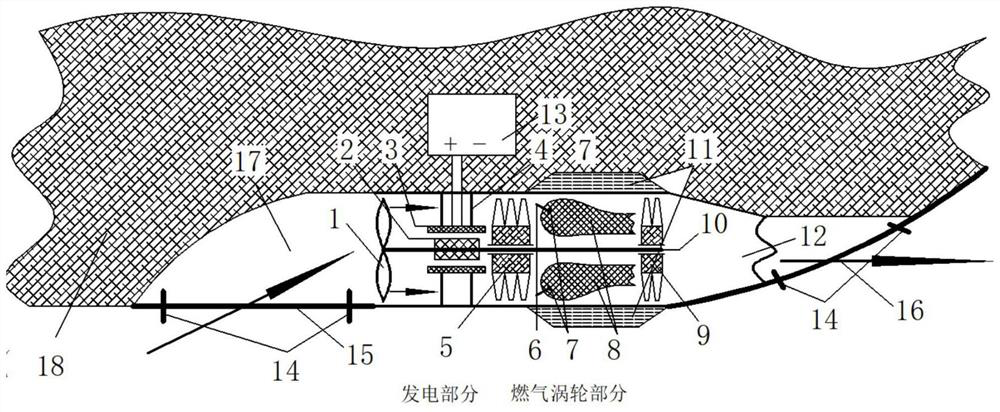

[0016] This patent has invented a power generation device based on the combustion of metal nanopowder, which can be used in aircraft backup power systems. The specific structure is composed of power generation part and gas turbine part, such as figure 1 shown. Its specific structure includes fan 1, motor rotor 2, motor stator 3, ring bracket 4, compressor 5, metal fuel inlet 6, nozzle 7, annular combustion chamber 8, turbine 9, generator main shaft 10, metal nano fuel 11, tail Nozzle 12, accumulator 13, explosion bolt 14, front machine cover 15, rear machine cover 16, air inlet duct 17, belly fuselage 18. In the structure of the device, the fan 1 of the power generation part, the motor rotor 2 and the generator main shaft 10 are fixedly connected, the motor stator 3 is fixed to the device housing by the ring bracket 4, and the gas turbine part is composed of a compressor 5, an annular combustion chamber 8 and a turbine 9.

[0017] When the aircraft stops due to main engine f...

specific Embodiment approach

[0019] This backup power supply is carried out when the aircraft engine stops for some reason and the APU system fails and makes an forced landing. The specific implementation is as follows:

[0020] 1. Open the front and rear machine covers of the device through the explosive bolt, and the incoming air generated by sliding enters the air inlet.

[0021] 2. The incoming air drives the fan to start the main shaft of the gas turbine, and then ignites the annular combustion chamber to fully burn with the metal nano powder to generate high-temperature and high-pressure gas to drive the turbine to do work.

[0022] 3. At this time, the main shaft of the gas turbine drives the generator, a part of the electric energy is supplied to the aircraft system, and the other part is stored in the battery.

[0023] 4. At the same time, the high-speed rotating fan inhales a large amount of air to fully burn it to produce high-temperature and high-pressure gas that is discharged at high speed ...

Embodiment 3

[0025] An aircraft auxiliary power generation mechanism based on metal nano-powder combustion, including fan 1, motor rotor 2, motor stator 3, ring support 4, compressor 5, metal fuel inlet 6, nozzle 7, annular combustion chamber 8, turbine 9, power generation Main shaft 10, metal nano-fuel 11, tail nozzle 12, battery 13, explosion bolt 14, front machine cover 15, rear machine cover 16, air inlet 17 and abdominal body 18; the air inlet 17 is located in the abdominal body At the bottom of 18, the air inlet and the air outlet of the air inlet are respectively equipped with a front machine cover 15 and a rear machine cover 16, and are fixed by explosive bolts; an annular bracket 4 is installed in the middle of the air inlet 17, and the outer ring of the annular bracket 4 It is fixed with the air inlet 17, and its inner ring is fixed with a motor stator 3; the motor stator 3 is coupled with the motor rotor 2; the motor rotor 2 is fixed on the generator main shaft 10; the motor main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com