Microwave-assisted rock breaking TBM cutter head for hard rocks

A microwave-assisted, cutter head technology, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve problems such as difficulty in ensuring tunnel construction period, increase equipment cost, tool wear, etc., and shorten construction period and project investment. , Increase the effect of rock breaking and increasing rock breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

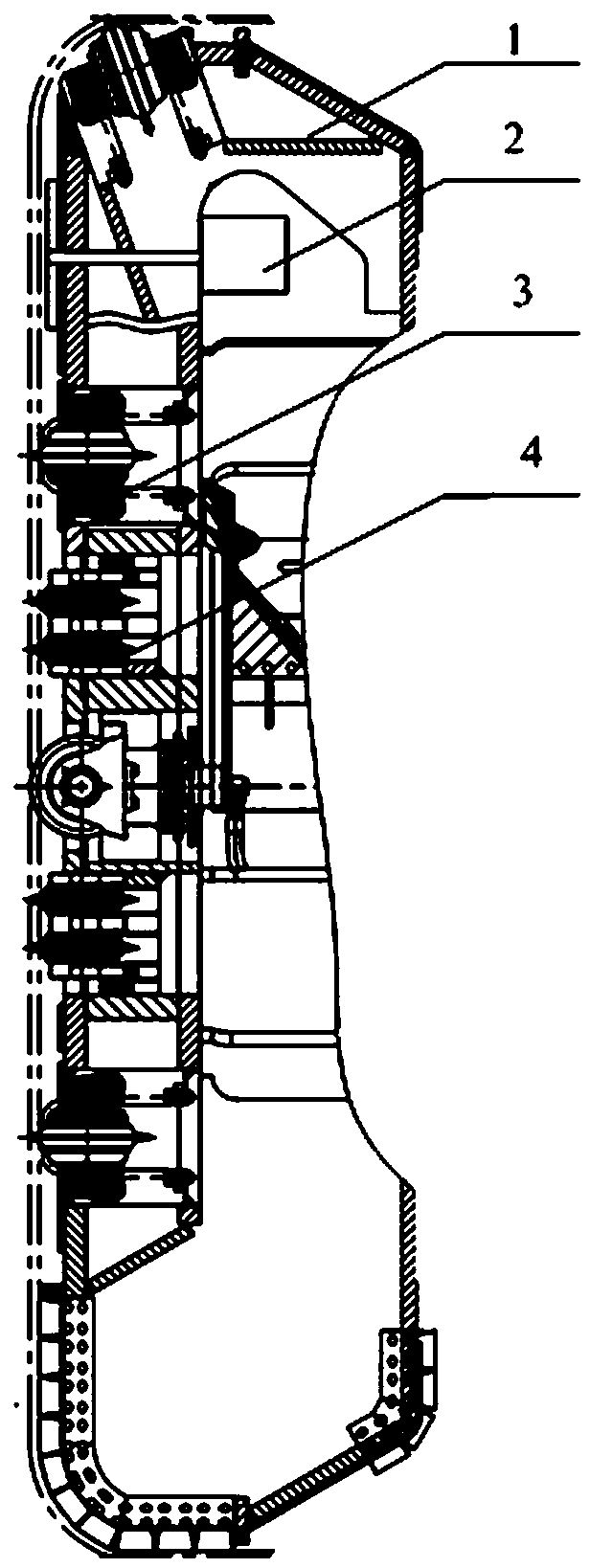

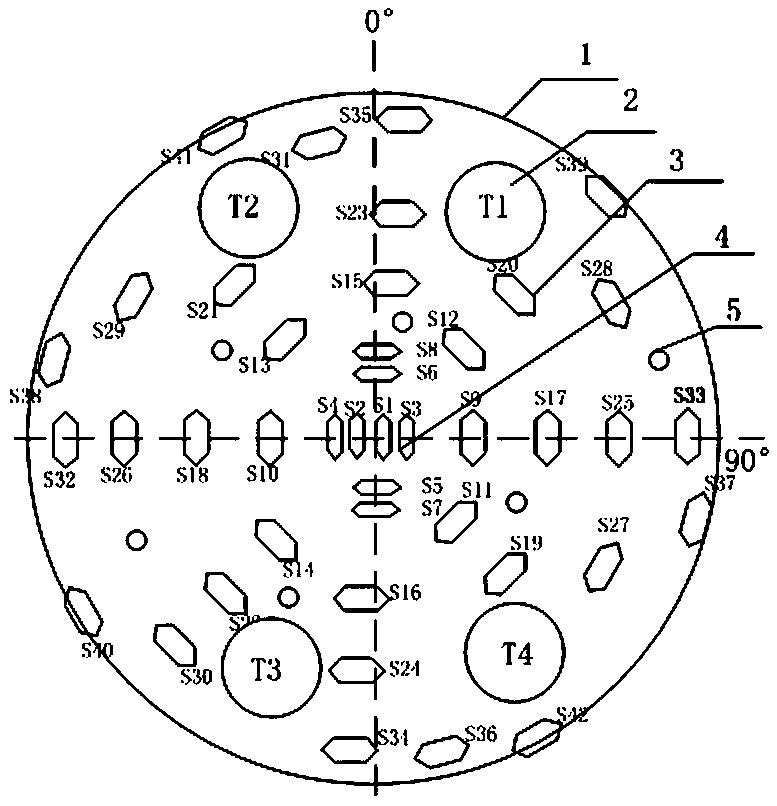

[0018] Such as figure 1 As shown, a microwave-assisted rock-breaking TBM cutterhead for hard rock according to the present invention includes a cutterhead body 1, a microwave emitting device 2, a single-edged hob 3, a double-edged hob 4, and a water spray and dust removal port 5. 4 double-edged hobs No. S1-S8 are arranged in the center of the cutter body 1, and a total of 34 single-edged hobs S9-S42 are arranged on the panel position. The hobs are arranged symmetrically, and the rock-breaking trajectory of each hob blade No coincidence, the number of hob arrangements can be reasonably increased or decreased according to the design diameter of the equipment. The water spray and dust removal ports 5 are arranged along the circumferential direction of the cutter head, and the number of water spray and dust removal ports can be reasonably increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com