L-shaped concrete prefabricated part

A technology of prefabricated concrete, L-shaped, applied in the direction of construction, building structure, etc., can solve the problems of misalignment and other problems, and achieve the effect of reducing the probability of separation, convenient use and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

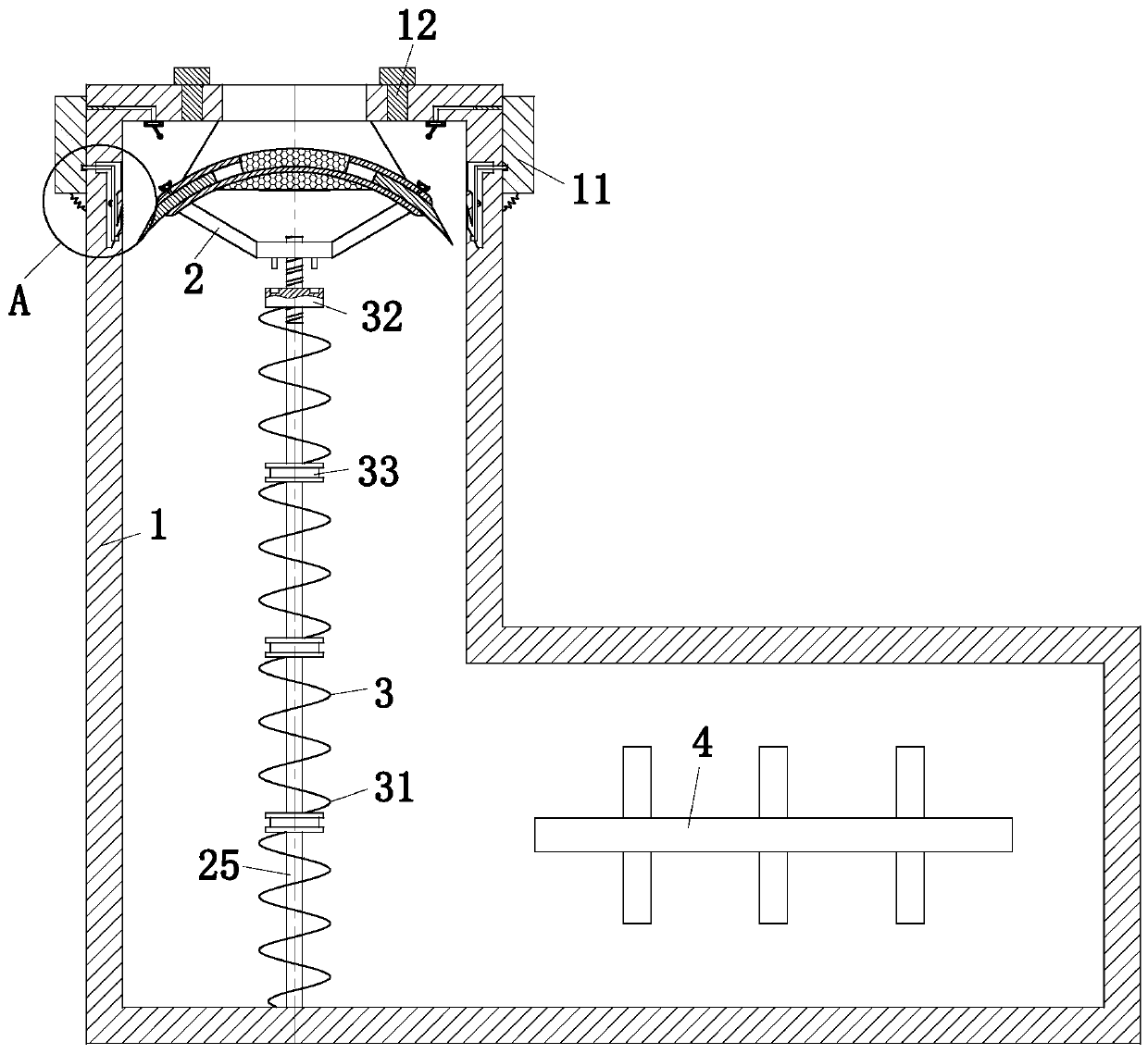

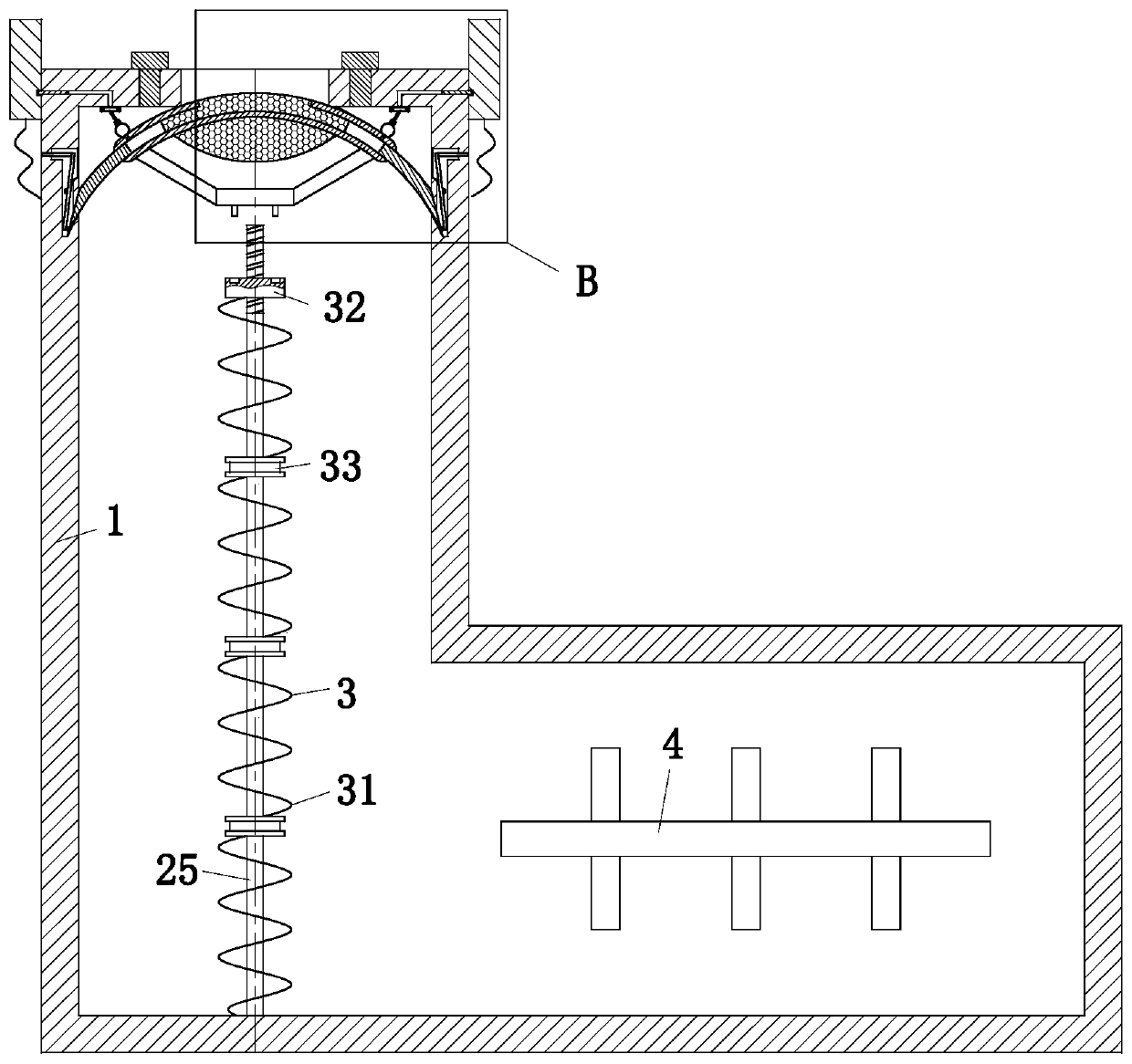

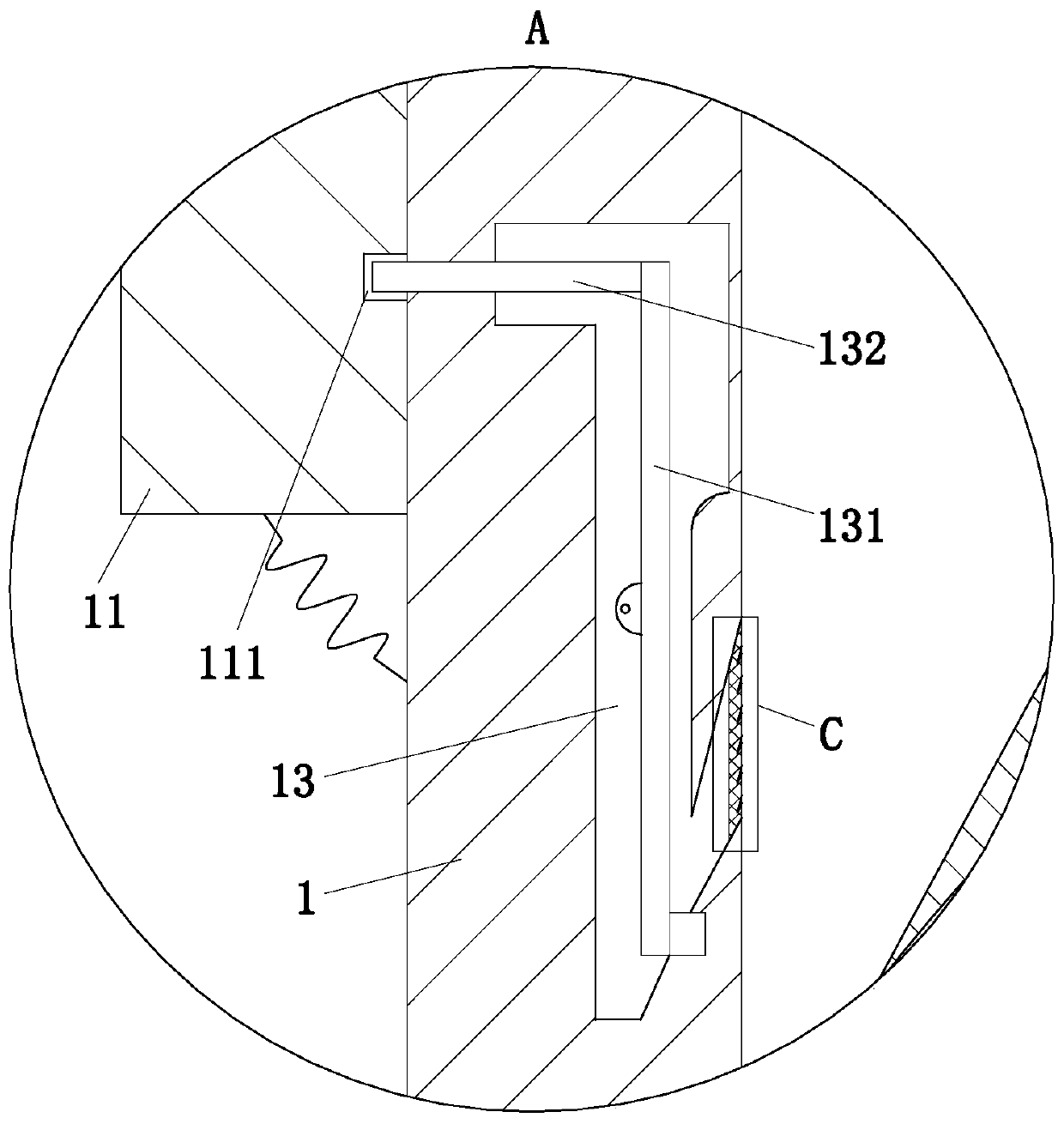

[0024] Such as Figure 1 to Figure 6 As shown, an L-shaped concrete prefabricated part includes an L-shaped shell 1, a connecting sleeve 11, a closed module 2, a shaking module 3 and an expansion column 4; the inside of the vertical section of the L-shaped shell 1 is provided with a closed module 2. The interior of the horizontal section of the L-shaped housing 1 is provided with an expansion column 4, and the outer side of the expansion column 4 is provided with a water-absorbing resin coating, and the outer side of one end of the vertical section of the L-shaped housing 1 is provided with a connecting sleeve 11. One end of the vertical section of the shell 1 is provided with a feed port, and two sealing bolts 12 are screw-embedded on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com