Energy-saving clay brick

An energy-saving clay technology, applied in the field of building materials, can solve the problems of high energy consumption and large clay resources for large-sized clay bricks, and achieve the effects of high pass rate, reduced production costs, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

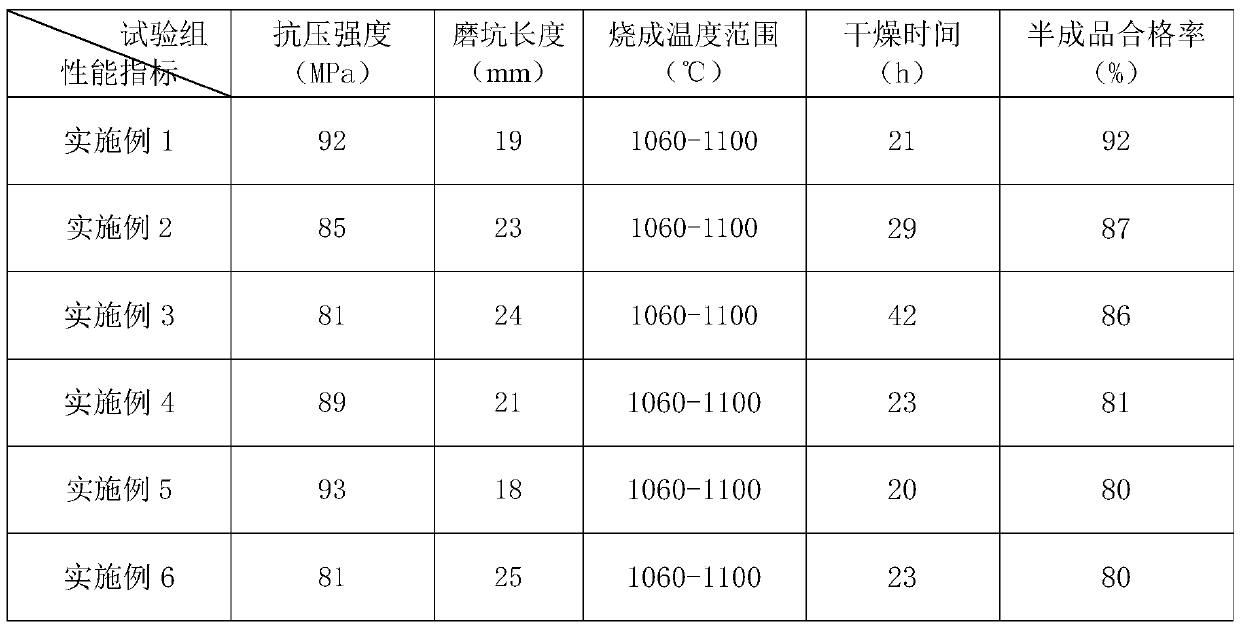

Examples

preparation example Construction

[0046] The preparation of the above-mentioned energy-saving clay brick comprises the following steps:

[0047] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and industrial waste;

[0048] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0049] (3) Carry out ball milling to raw material, the particle diameter of raw material is controlled at 200 orders, and water content is controlled at 48%;

[0050] (4) squeeze mud dehydration: the material that step (3) obtains is carried out squeeze mud dehydration, the moisture content of material is controlled at 18%;

[0051] (5) Vacuum mud refining: the material obtained in step (4) is initially refined, and the vacuum degree is controlled at 0.5MPa; after the initial refining is completed, it will be old for 5 days;

[0052] (6) Vacuum forming: the vacuum degree is controlled at 0.9MPa during th...

Embodiment 2

[0056] This embodiment discloses an energy-saving clay brick, which comprises the following raw materials: Chongqing clay, Renshou clay, Guihua town clay and industrial waste residues, wherein the weight ratio of the Chongqing clay, Renshou clay and Guihua town clay is 40%; The mass ratio of Chongqing clay, Renshou clay and Guihua town clay is 1:0.8:2.1. In this embodiment, the industrial waste slag is specifically selected from iron and steel plant waste slag and waste red brick, and the mass ratio of iron and steel plant waste slag to waste red brick is 1:0.5.

[0057] The preparation of the above-mentioned energy-saving clay brick comprises the following steps:

[0058] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and industrial waste;

[0059] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0060] (3) Carry out ball milling to raw...

Embodiment 3

[0067] This embodiment discloses an energy-saving clay brick, which includes the following raw materials: Chongqing clay, Renshou clay, Guihua town clay and industrial waste residues, the weight ratio of the Chongqing clay, Renshou clay and Guihua town clay is 45%; The mass ratio of Chongqing clay, Renshou clay and Guihua town clay is 0.8:1:2.1. In this embodiment, the industrial waste slag is specifically selected from iron and steel plant waste slag and waste red brick, and the mass ratio of iron and steel plant waste slag to waste red brick is 1:0.5.

[0068] The preparation of the above-mentioned energy-saving clay brick comprises the following steps:

[0069] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and industrial waste;

[0070] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0071] (3) Carry out ball milling to raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com