MEMS driver based on zipper teeth and working method of MEMS driver

A driver and zipper technology, which is applied in the field of micro-electromechanical systems, can solve the problems of large structure, difficult laser design, small tuning range, small rotation radius, and small tuning range of rotation radius, and achieve the effect of compact structure, long rotation radius, and large tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

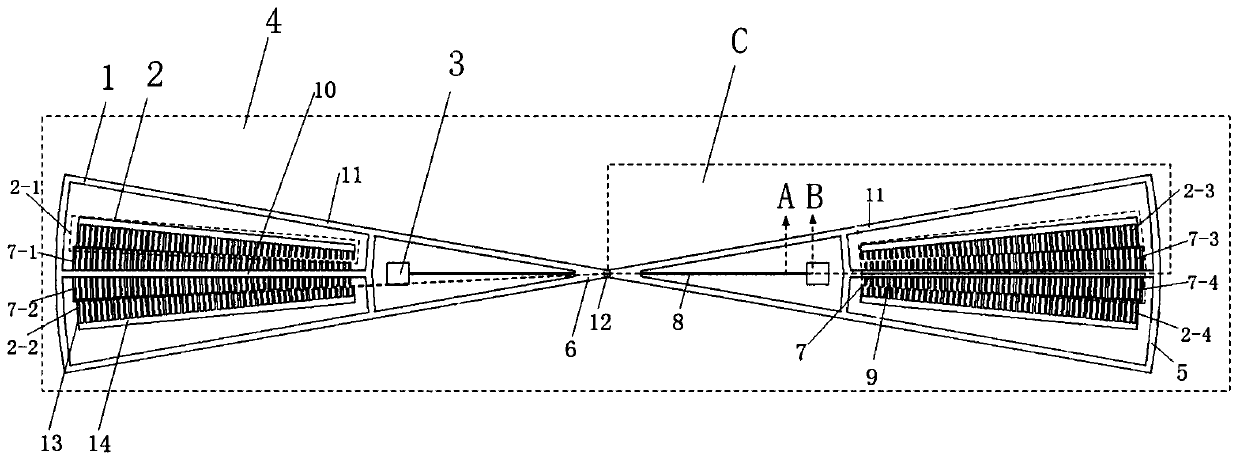

[0045] A zipper comb based MEMS actuator such as Figure 1~4 As shown, it includes a movable part 1, a fixed comb 2, a fixed anchor point 3 and a base layer 4, and the fixed comb 2 and the fixed anchor point 3 are fixed on the base layer 4;

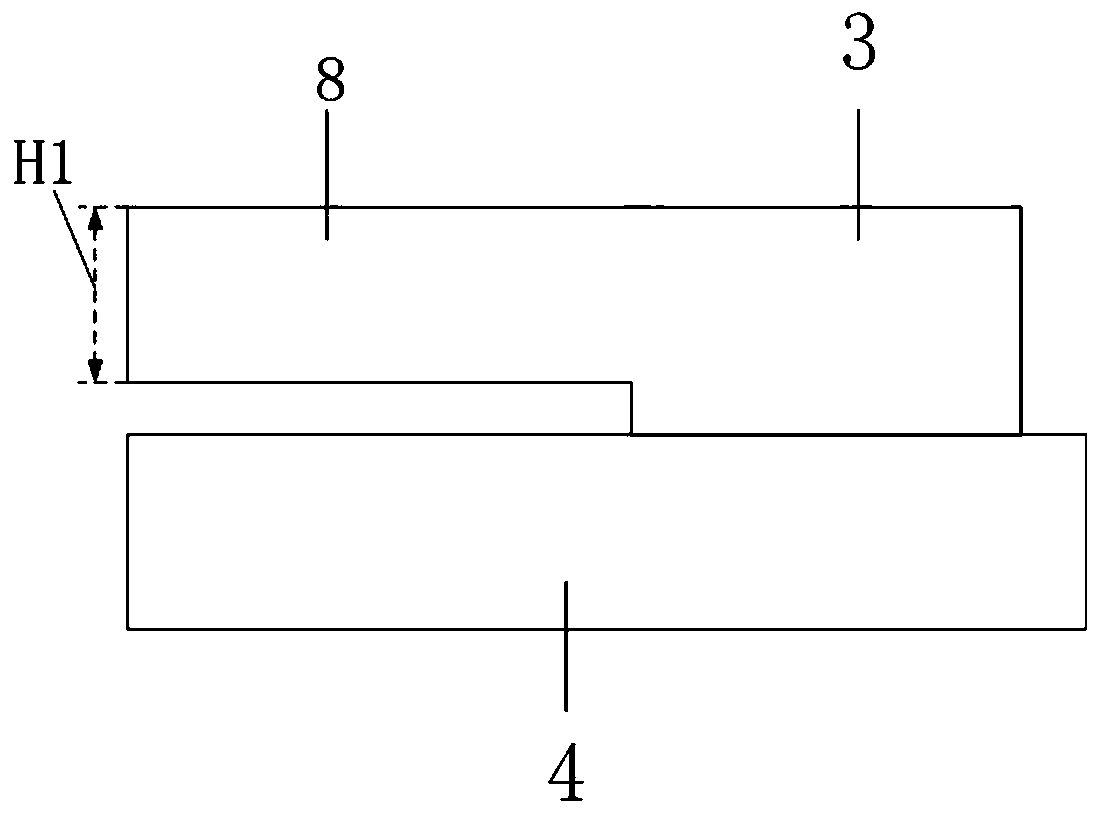

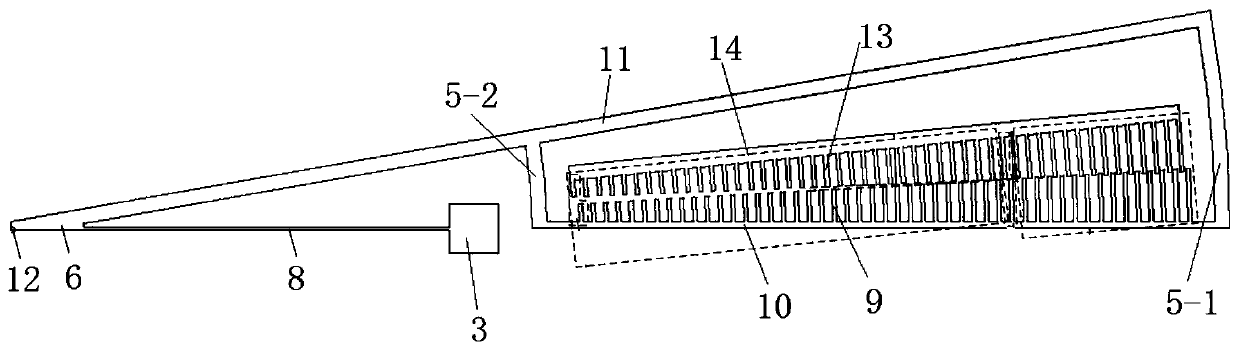

[0046] The movable part 1 includes a radial truss, an arc truss 5, a connecting part 6, a movable comb 7 and an elastic beam 8, and the arc truss 5 is arranged on the arc position with the imaginary axis point 12 as a circle. At the arc position corresponding to the radius, the radial truss is arranged along the radial direction, and the radial truss includes a first radial truss 10 connected with the movable comb 9 and a second radial truss connected with the converging end of the connecting part 6 to the truss 11, the first radial truss 10 and the second radial truss 11 and the arc truss 5 (here the arc truss 5 includes the first radial truss 10 and the second radial truss The arc truss 5-1 at the end of 11 and the arc truss 5-2 locate...

Embodiment 2

[0051] A kind of MEMS driver based on the zipper comb, the structure is as shown in embodiment 1, and its difference is that, in every pair of fixed comb 2 and movable comb 7, the logarithm of fixed comb and movable comb is 49 pairs, does not apply When the voltage is applied, the initial overlapping comb teeth of the fixed comb 2 and the movable comb 7 are the 15th pair of comb teeth counted from the outside. In the present invention, the logarithm of the fixed comb and the movable comb generates enough driving force, and leaves enough length for the elastic beam to make the driver rotate around the imaginary axis, and the unilateral rotation is preferably more than 2.5°.

Embodiment 3

[0053] A kind of MEMS driver based on zipper comb, the structure is as shown in embodiment 2, and its difference is that the center angle corresponding to the outermost movable comb and fixed comb is 3 °, and the width is 8m, in order to ensure the structure It is compact and can be designed with a rotation angle of no more than 3° on one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com