Phosphorus pentoxide transportation protection barrel

A technology of phosphorus pentoxide and protection barrels, applied in the field of phosphorus pentoxide, can solve problems such as danger and leakage of phosphorus pentoxide, and achieve the effect of strengthening the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

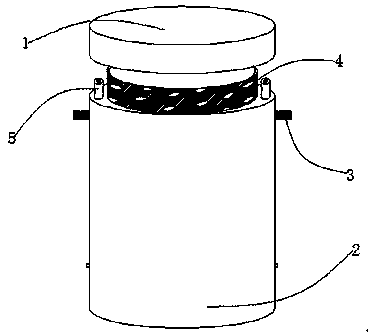

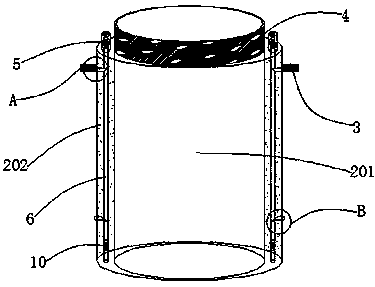

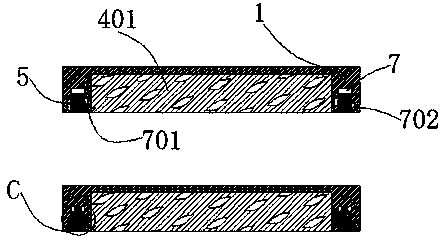

[0029] As attached figure 1 Attached Picture 10 Shown:

[0030] The present invention provides a phosphorus pentoxide transport protection barrel, which includes a lid 1, a shell 2, a storage room 201, a filling room 202, a handle 3, a groove 301, a barrel mouth 4, an inner wall groove 401, a pillar 5, and a circular opening 501. Upper clamping block 502, lower clamping block 503, receiving column 6, magnet 601, annular groove 7, upper annular bayonet 701, lower circular bayonet 702, upper object 8, concave bayonet 801, lower object 9 And spring 10; inside the housing 2 is provided with a storage room 201, between the storage room 201 and the housing 2 is the filling room 202, the receiving post 6 is located on both sides of the housing 2, and located in the middle of the storage room 201 and the housing 2, to accept The bottom of the column 6 is provided with a spring 10, the upper part of the shell 2 is provided with a barrel mouth 4 corresponding to the storage room 201, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com