Orbital type coal transporting trestle automatic polling robot and system

An automatic inspection, orbital technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inability to apply dust, high dust concentration, high temperature and humidity, etc., to improve environmental adaptability, convenient adjustment of friction force, and reduce the degree of distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

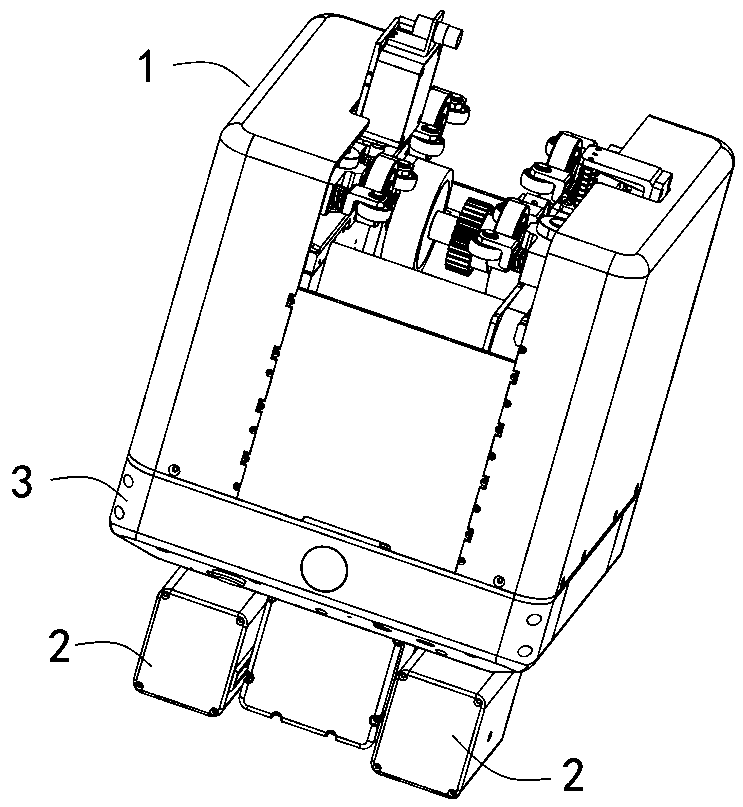

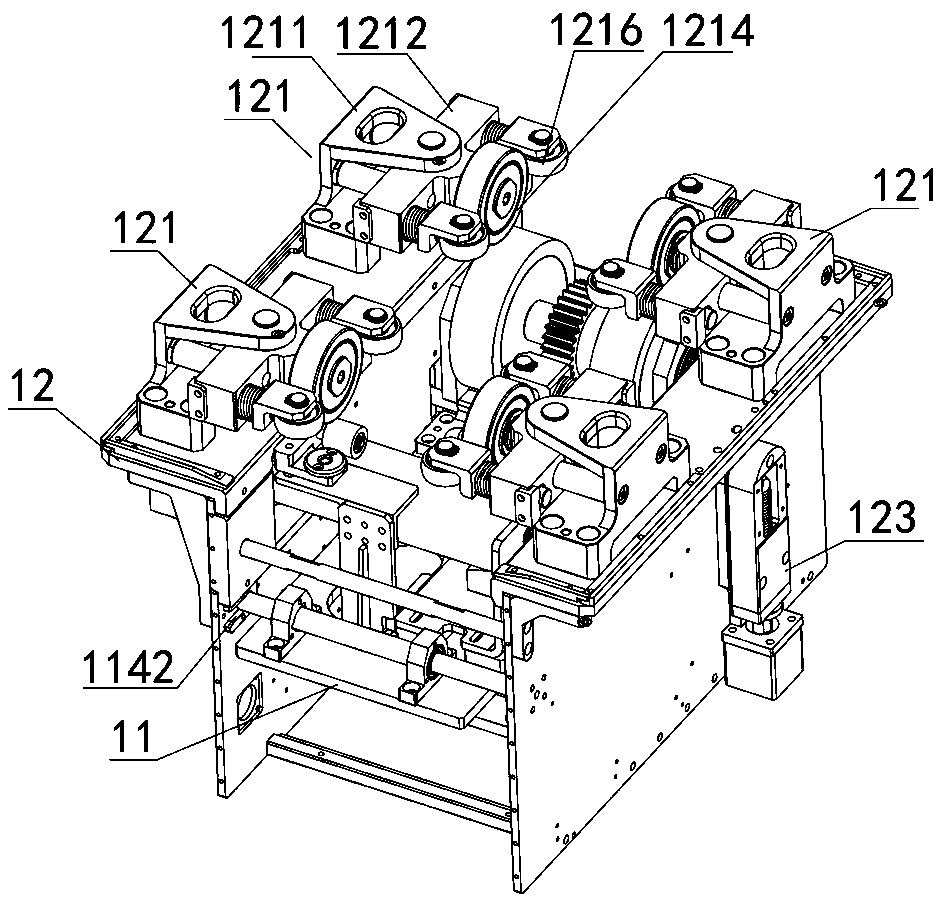

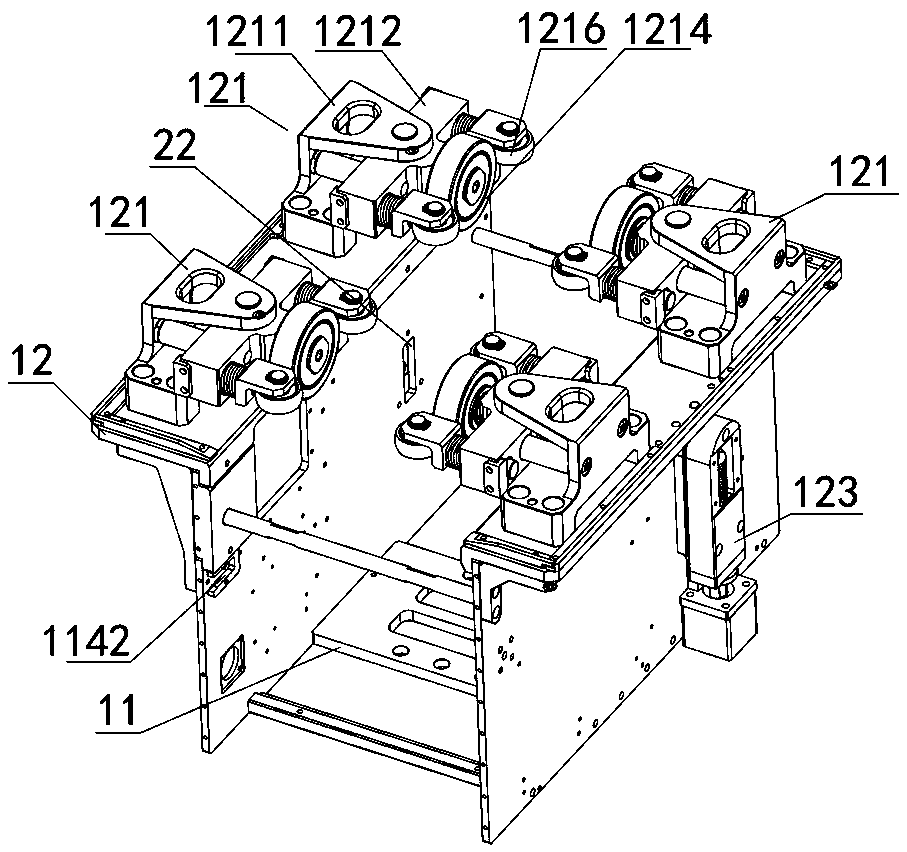

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, the present embodiment provides an automatic inspection robot for rail-type coal conveying trestles, including a cabin 3 with a rail travel mechanism 1 and inspection image acquisition equipment 2, the cabin 3 is a closed structure and has a wireless charging receiving module, And the cabin 3 is provided with a power supply module, a control module and a wireless communication module, the power supply module, the wireless charging receiving module, the wireless communication module, the track running mechanism 1, and the inspection image acquisition device 2 are connected to the control module respectively, and the track running mechanism 1 includes The traveling driving device 11 and the main frame 12, the main frame 12 is provided with a guide load-bearing wheel assembly 121 and a pair of sliding grooves 122, and the two sides of the traveling driving device 11 are provided with connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com