A method to realize the addition of stand-by stand after online roll change and roll withdrawal of ESP finishing mill

A technology for finishing rolling mills and racks, which is applied to rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as inability to produce thin-gauge strips with surface quality, frequent roll changes, and roll wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with the accompanying drawings.

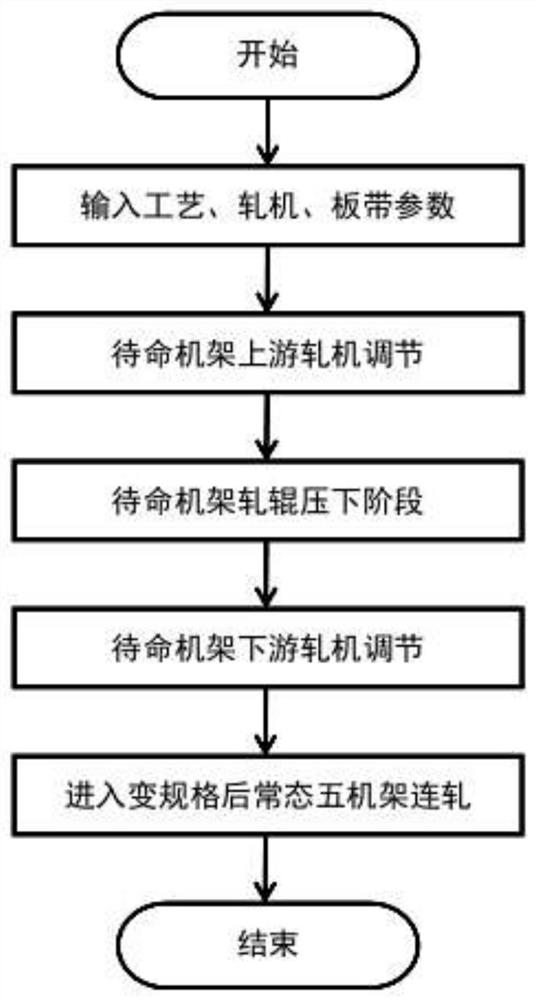

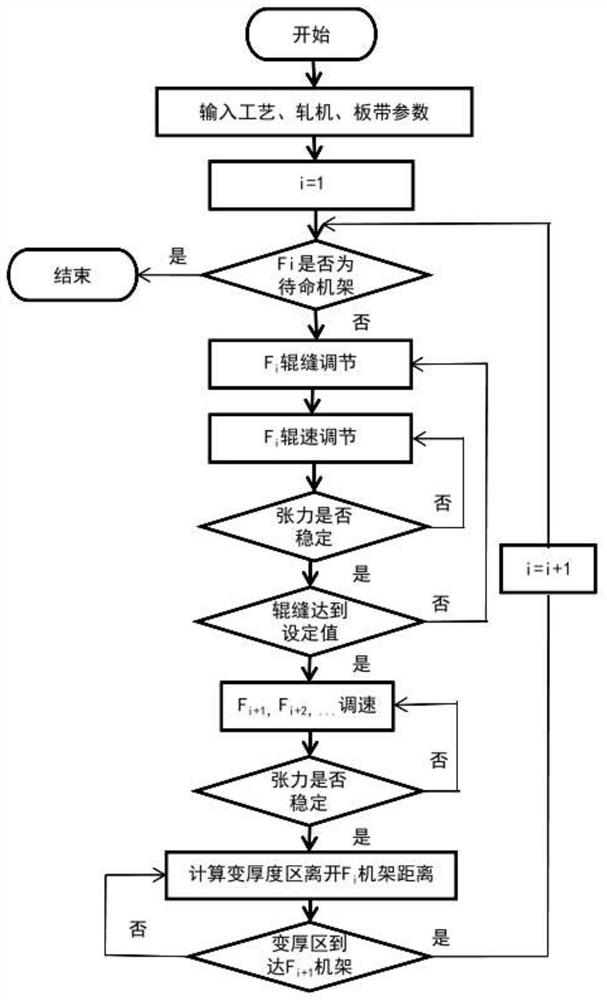

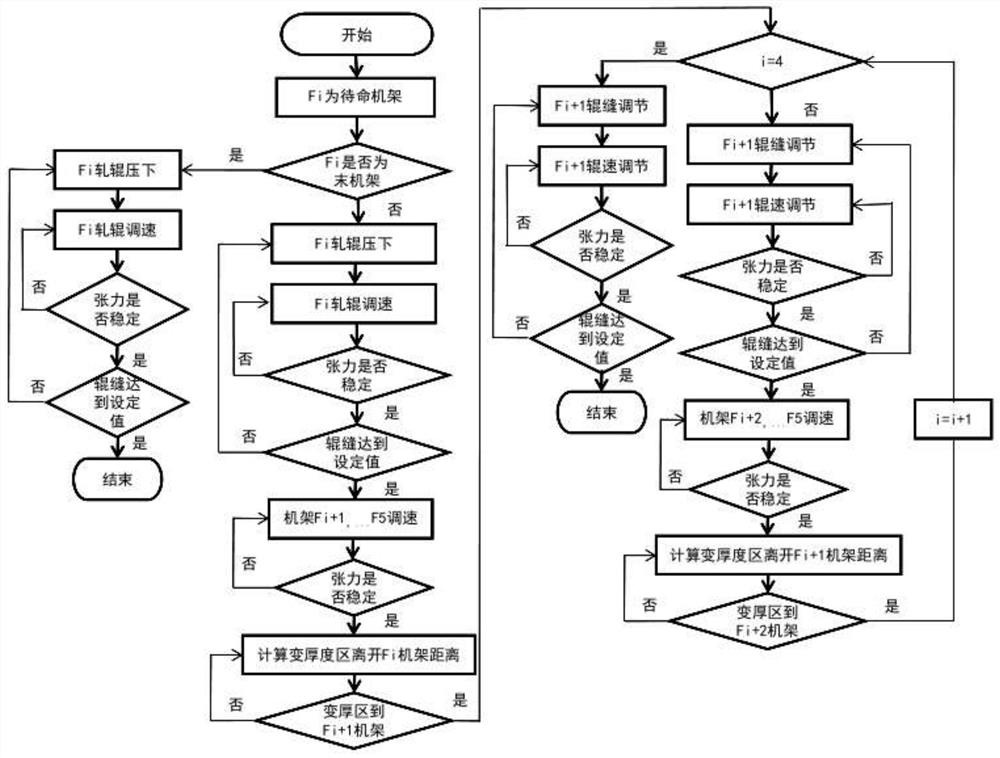

[0116] A method for realizing ESP finishing mill line changing rolls on-line and withdrawing rolls and then adding stand-by stands. Through the program transformation of rolled products, the abnormal rolling of four stands is changed to the normal rolling of five stands, and the five stands F respectively 1 , F 2 , F 3 , F 4 and F 5 , the distance between the five racks before the roll is preset is equal, all of which are L. Preferably, the distance between each rack is 4.5 meters. like Figure 1 to Figure 3 As shown, in the present invention, the method for adding the stand-by stand after the on-line roll change and withdrawal of the ESP finishing mill is realized. According to the rolling process parameters, strip parameters and rolling mill parameters, each stand needs to be adjusted. First, the stand-by stand is determined. Frame F i , each frame upstream o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com