Variable-frequency type oil-water separating equipment

An oil-water separation, frequency conversion technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems that the separation effect cannot meet the requirements, it is difficult to understand the reaction situation, and there is no alarm device, so as to prevent secondary pollution. , increase the service life, increase the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

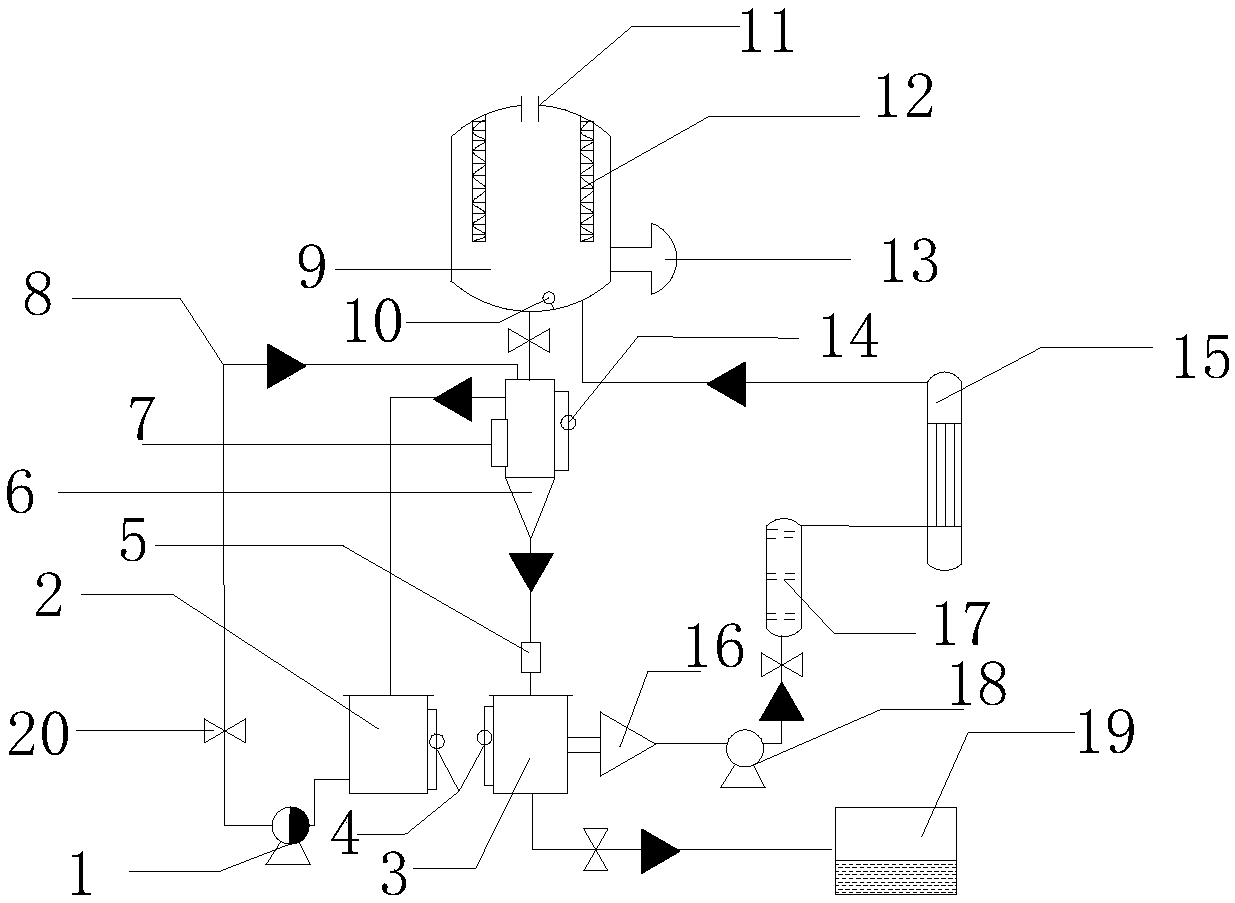

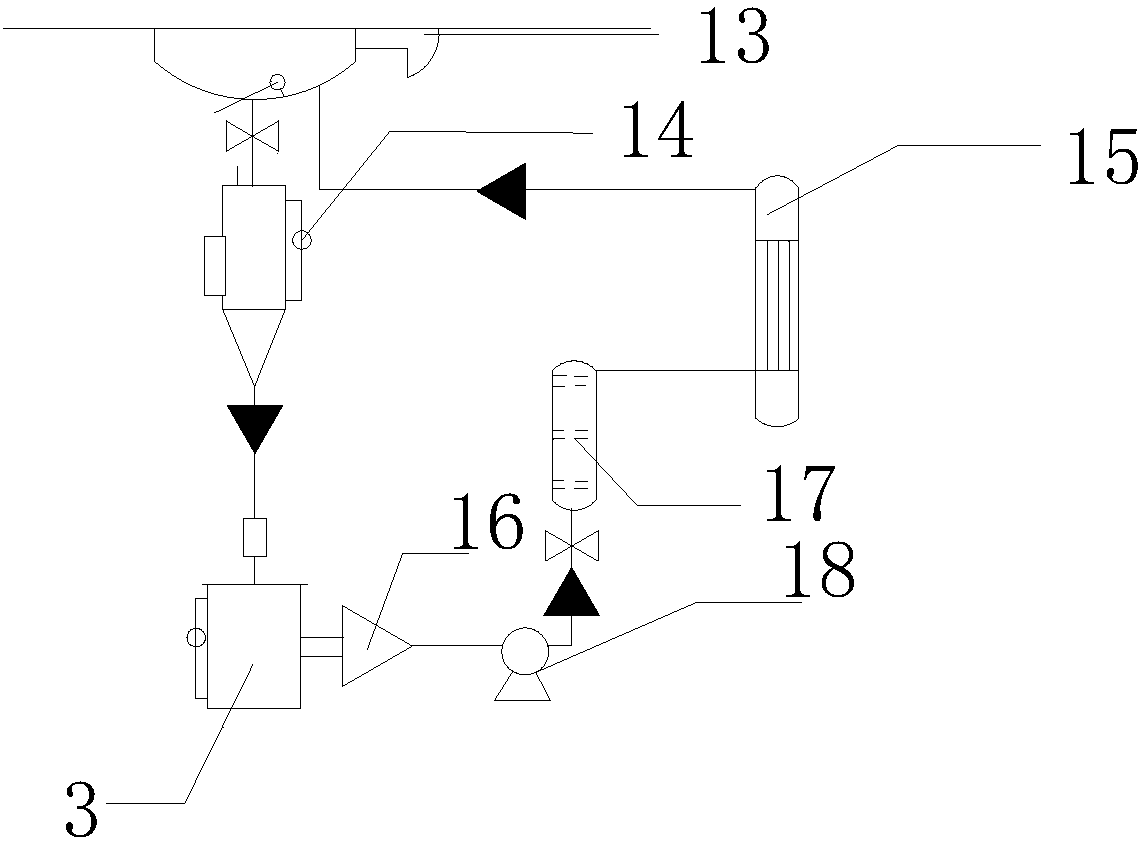

[0014] A frequency conversion type oil-water separation equipment, the structure of which includes a clear liquid delivery pump 1, a clear liquid storage tank 2, a turbid liquid storage tank 3, a boundary gauge 2 4, a static mixer 5, a sedimentation separation tank 6, and a liquid ammonia injection port 7 , anti-corrosion conveying pipeline 8, reaction kettle 9, high temperature resistant temperature detector 10, feed inlet 11, heating pipe 12, temperature alarm 13, boundary gauge 14, heat exchanger 15, two-way suspension separator 16, Membrane filter 17, turbid liquid delivery pump 18, settling tank 19, control valve 20; described clear liquid delivery pump 1 is connected with clear liquid storage tank 2 through anticorrosion delivery pipeline 8, and described clear liquid storage tank 2, turbid solution The liquid storage tank 3 is connected with the sedimentation separation tank 6, and the sedimentation separation tank 6 is connected with the liquid ammonia injection port 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com