Shower gel processing system, shower gel processing method and shower gel

A processing system, shower gel technology, applied in chemical instruments and methods, dissolving, bottle filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

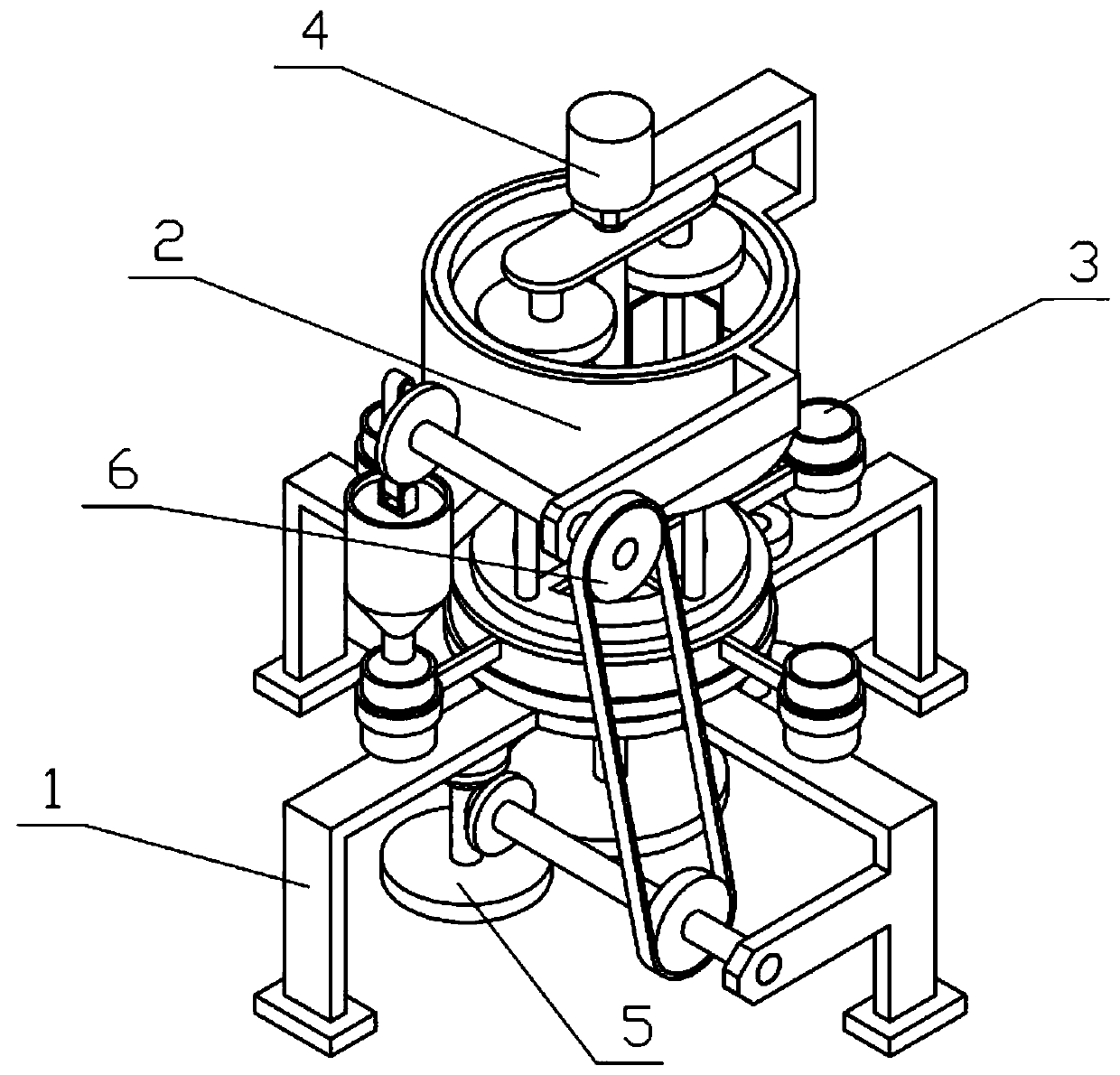

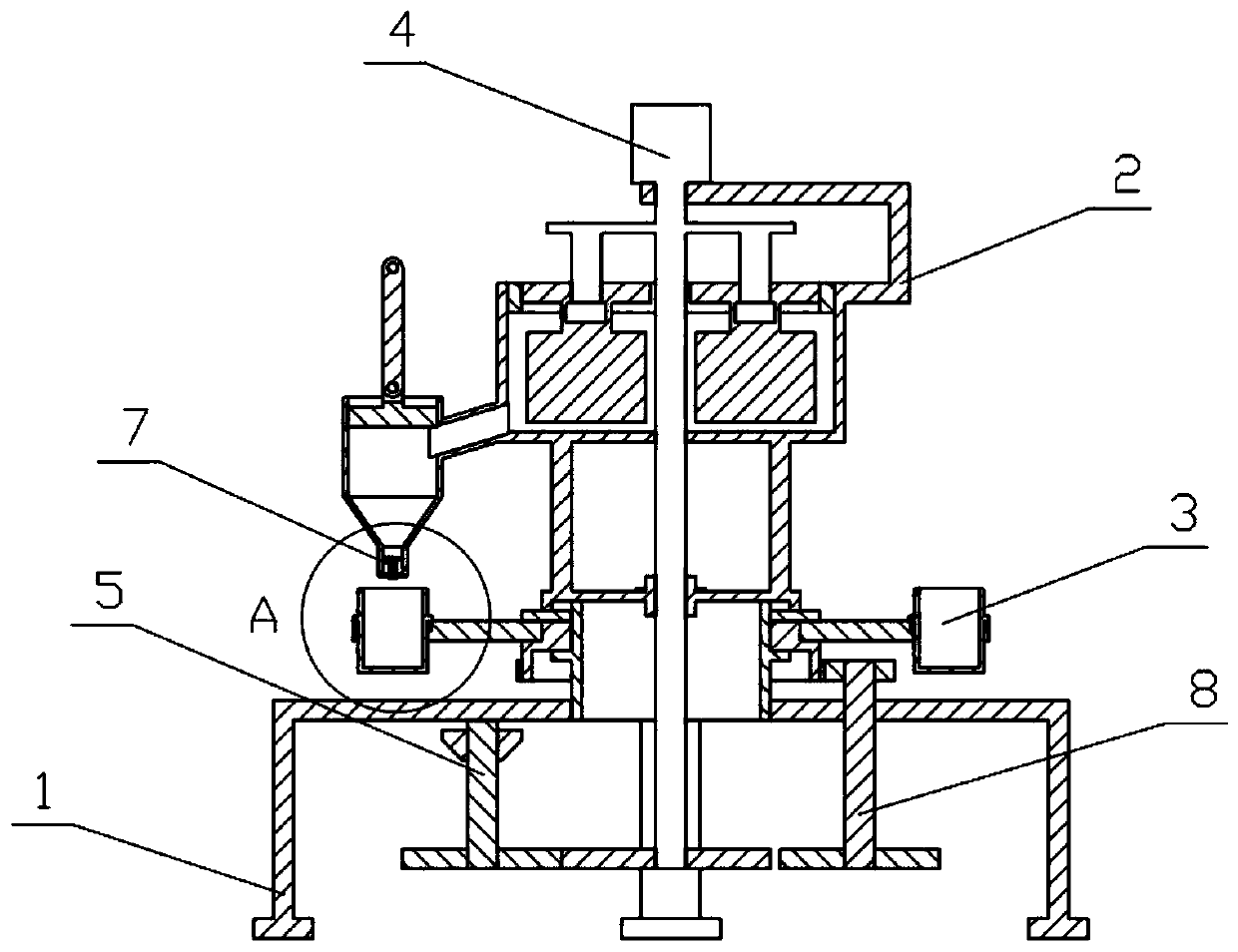

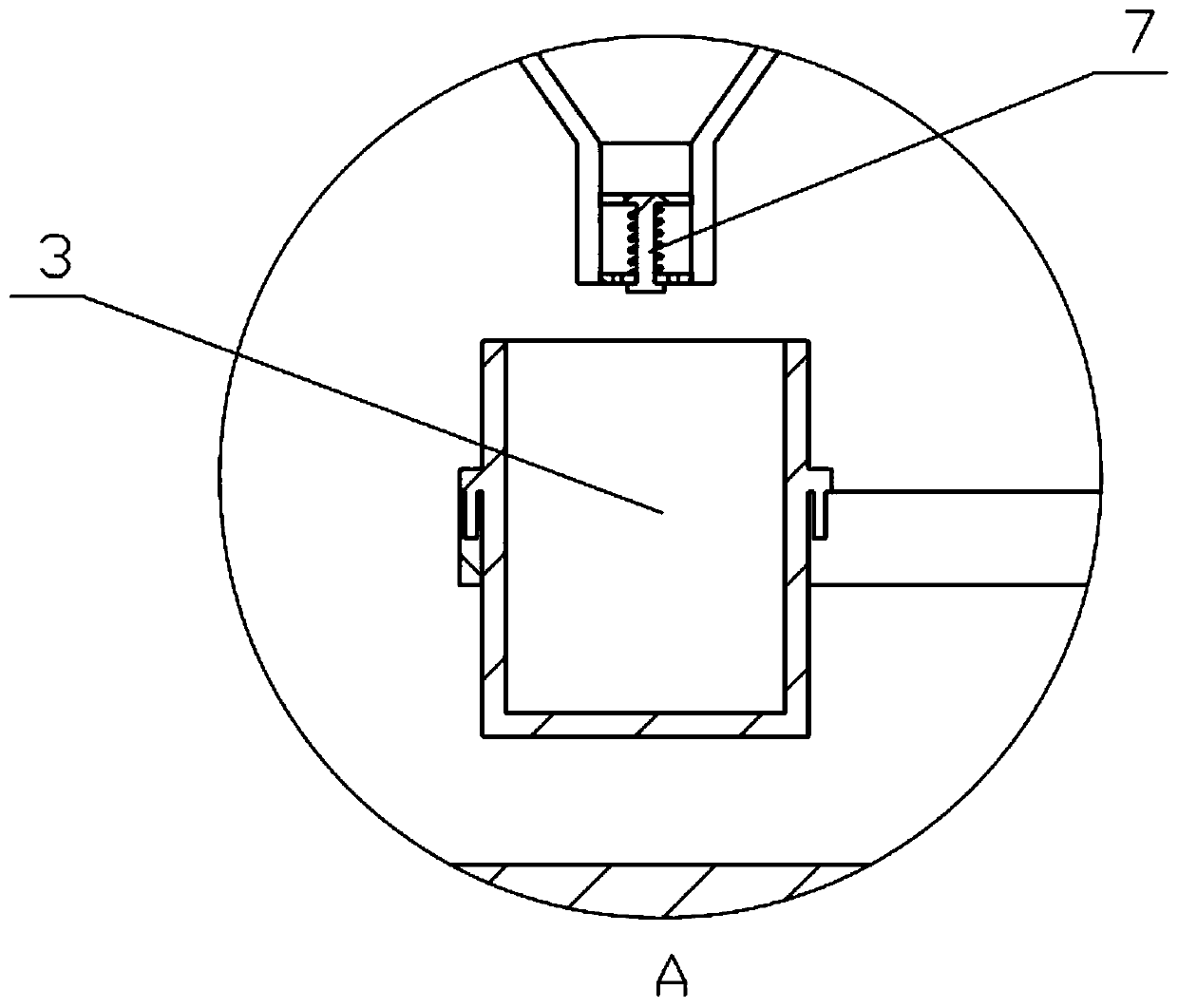

[0037] Combine below Figure 1-12Describe this embodiment, a shower gel processing system, including a processing support 1, a stirring support 2, a replacement mechanism 3, a power mechanism 4, a transmission mechanism I5, an extrusion mechanism 6, a one-way mechanism 7, and a transmission mechanism II8. The support 2 is fixedly connected to the processing support 1, the replacement mechanism 3 is rotatably connected to the processing support 1, the upper end of the power mechanism 4 is fixedly connected to the stirring support 2, the lower end of the power mechanism 4 is rotatably connected to the processing support 1, and the transmission mechanism I5 rotates Connected to the processing support 1, the transmission mechanism Ⅰ5 and the power mechanism 4 are meshed for transmission, the extrusion mechanism 6 is installed on the stirring support 2, the extrusion mechanism 6 and the transmission mechanism Ⅰ5 are connected by a belt transmission, and the extrusion mechanism 6 dri...

specific Embodiment approach 2

[0038] Combine below Figure 1-12 This embodiment will be described. This embodiment will further describe Embodiment 1. The processing bracket 1 includes a processing bracket 1 including a support ring 1-1, an installation cylinder 1-2, a support foot 1-3, and a support plate 1-4. The ring 1-1 is fixedly connected with an installation cylinder 1-2, and the supporting ring 1-1 is evenly fixedly connected with four supporting legs 1-3, and one of the supporting legs 1-3 is fixedly connected with a supporting plate 1-4.

specific Embodiment approach 3

[0039] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the stirring bracket 2 includes a mixing drum 2-1, a ring gear 2-2, a motor support plate 2-3, a rotating support plate 2-4, a connecting plate 2-5, connecting column 2-6, discharge frame 2-7 and extrusion cylinder 2-8, the upper end of the mixing cylinder 2-1 is fixedly connected with the ring gear 2-2, and the mixing cylinder 2-1 is fixedly connected with the motor The support plate 2-3 and the rotating support plate 2-4, the connection column 2-6 are fixedly connected between the connection plate 2-5 and the mixing drum 2-1, the discharge frame 2-7 is inclined, and the discharge frame 2-7 Fixedly connected to the mixing drum 2-1, the discharge rack 2-7 is connected to the mixing drum 2-1, the extrusion drum 2-8 is fixedly connected to the discharge rack 2-7, and the extrusion drum 2-8 is connected to the discharge rack 2-8. The frame 2-7 is connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com