Integrated reducible activated carbon filter cylinder waste gas treatment device

A waste gas treatment device, activated carbon technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the frequency of cleaning and maintenance, reducing the performance of the adsorption device, and difficult operation, etc., to improve equipment manufacturing and Construction efficiency, reduction of air ducts and connecting fittings, simplified control of conversion system effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be described in detail below in conjunction with specific embodiments.

[0034] The main purpose of the integrated reducible activated carbon filter cartridge exhaust gas treatment device of the present invention is to provide a flexible and free switching between working and maintenance states, while maintaining the continuous working performance of the exhaust gas treatment device during the entire process, avoiding idleness, and ensuring large-scale The continuous and stable process of waste gas treatment or high-frequency and continuous waste gas treatment projects can improve the efficiency of waste gas treatment, reduce the maintenance workload of activated carbon waste gas treatment devices, and reduce production costs.

[0035] The technical solutions of the present invention will be described in detail below with preferred embodiments.

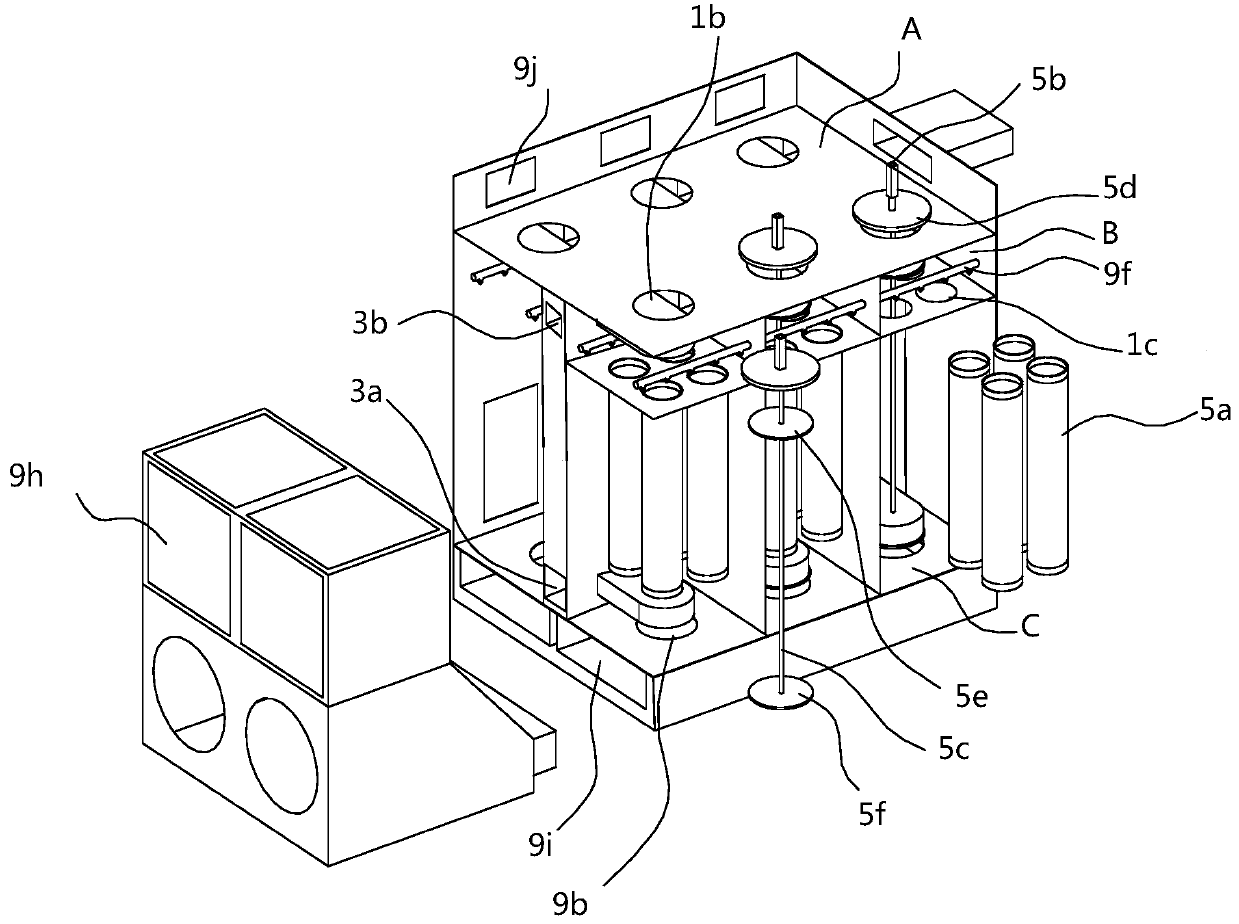

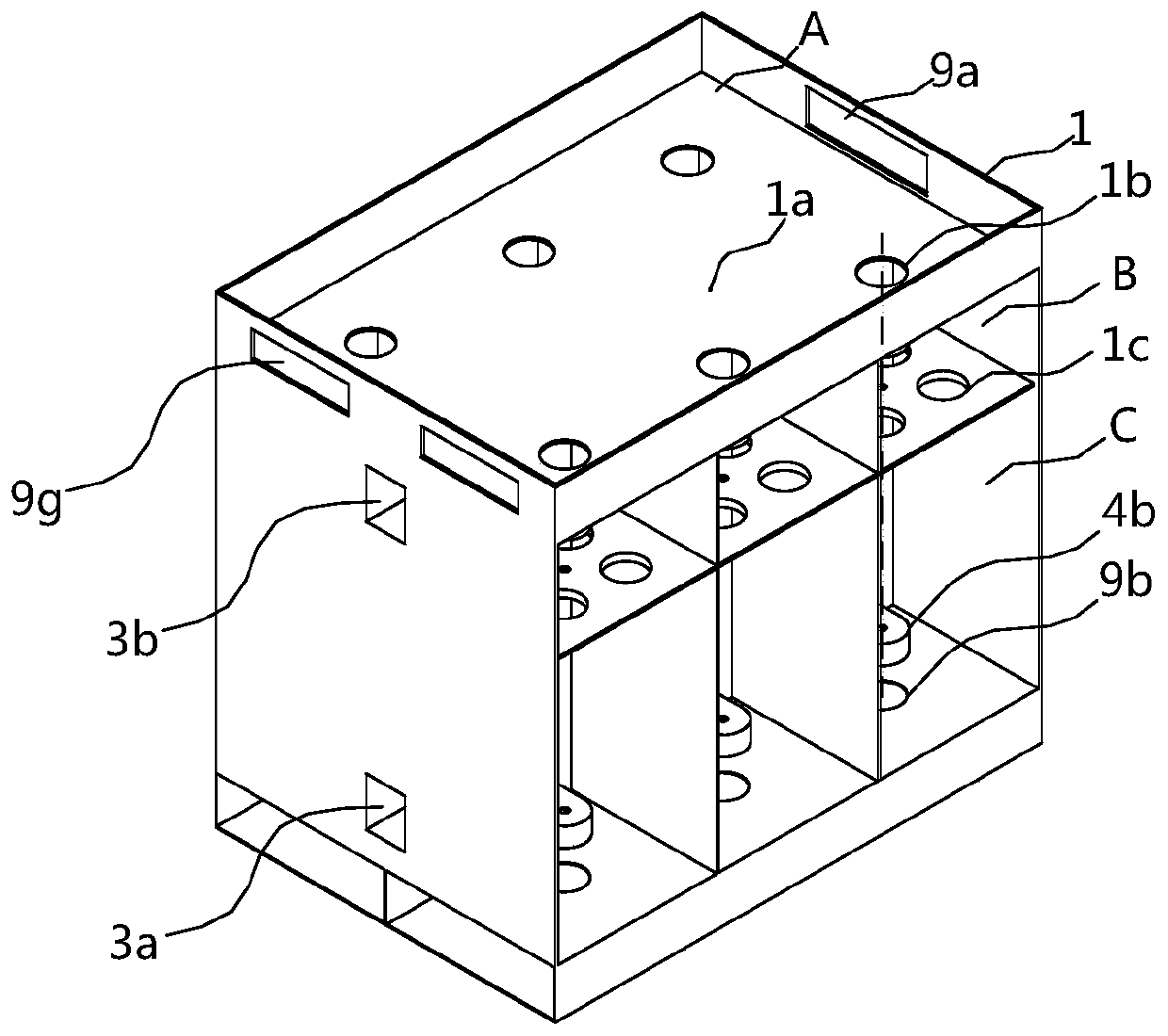

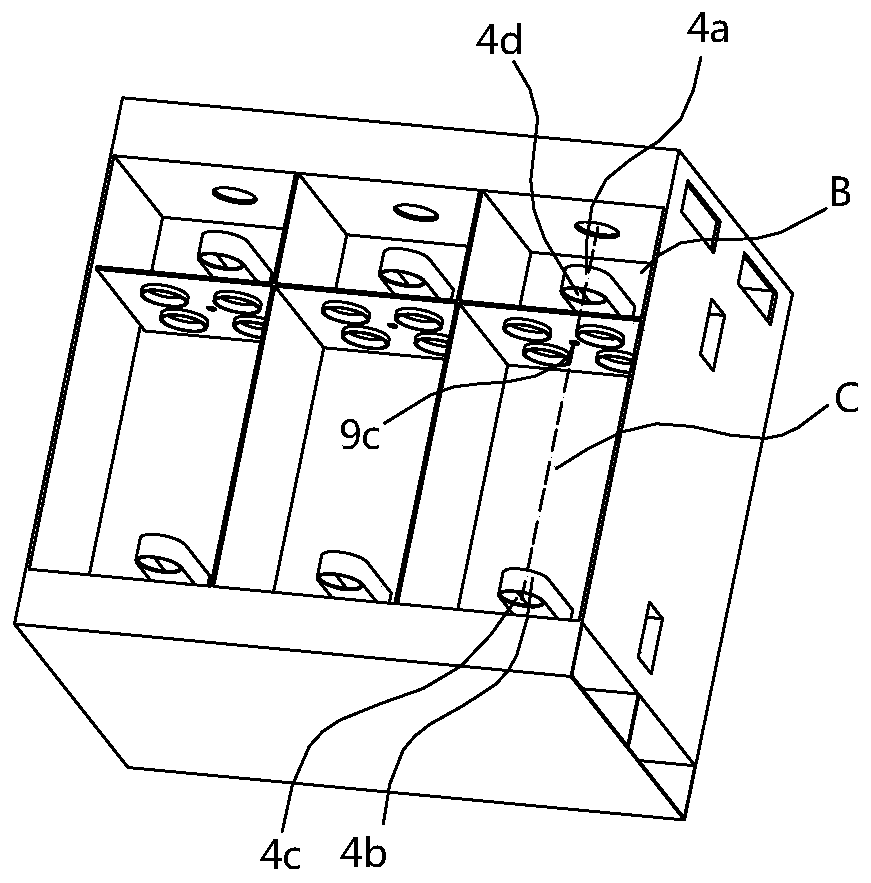

[0036] Such as figure 1 As shown, the integrated reducible activated carbon filter cartridge exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com