Stator tooth module, stator, motor and winding method of winding in stator tooth module

A stator tooth and winding technology, applied in the field of stator tooth module, stator, motor, and winding winding, can solve the problems of high winding manufacturing cost, reduced slot full rate, and high requirements for winding machines, and achieves convenient winding and low requirements. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

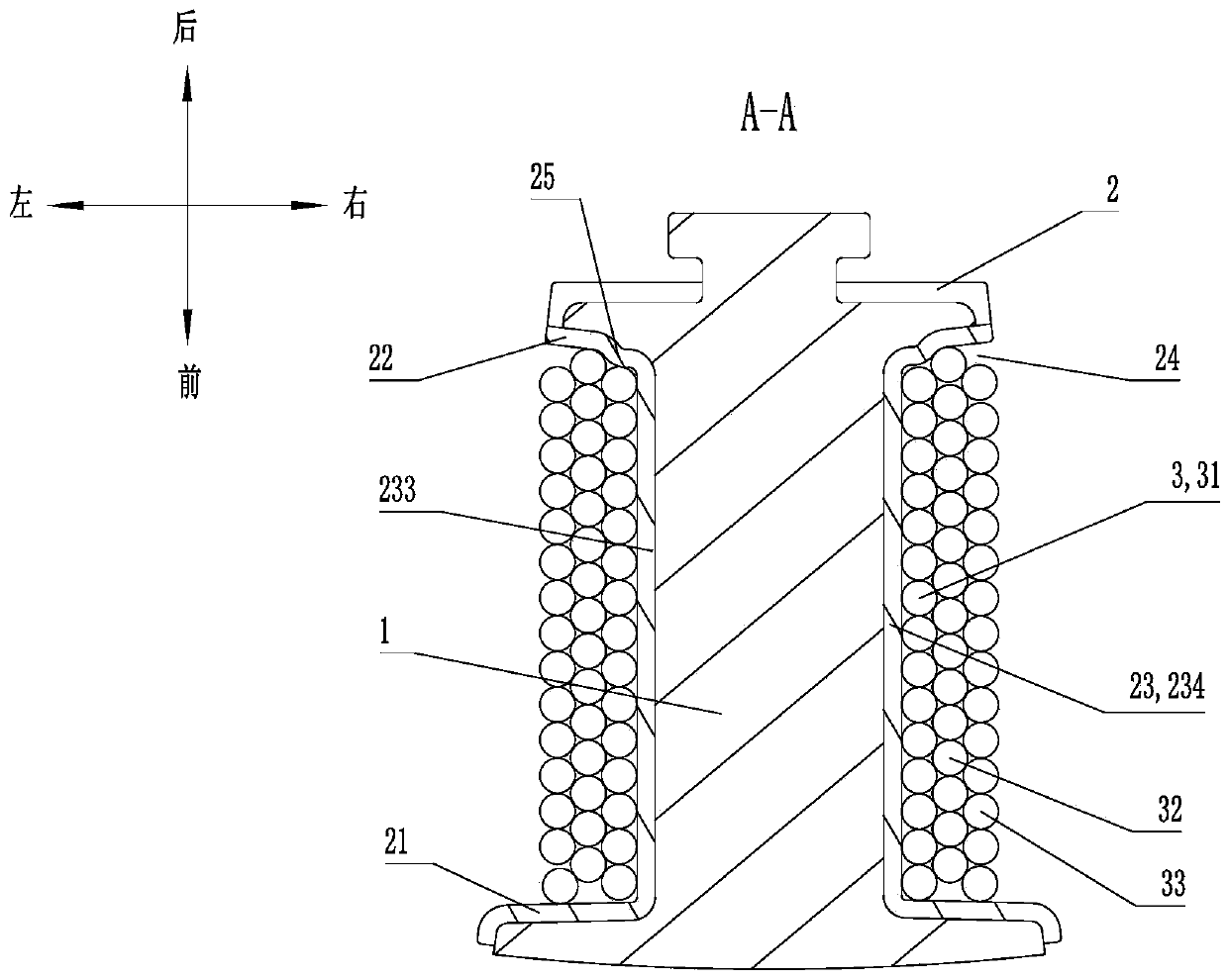

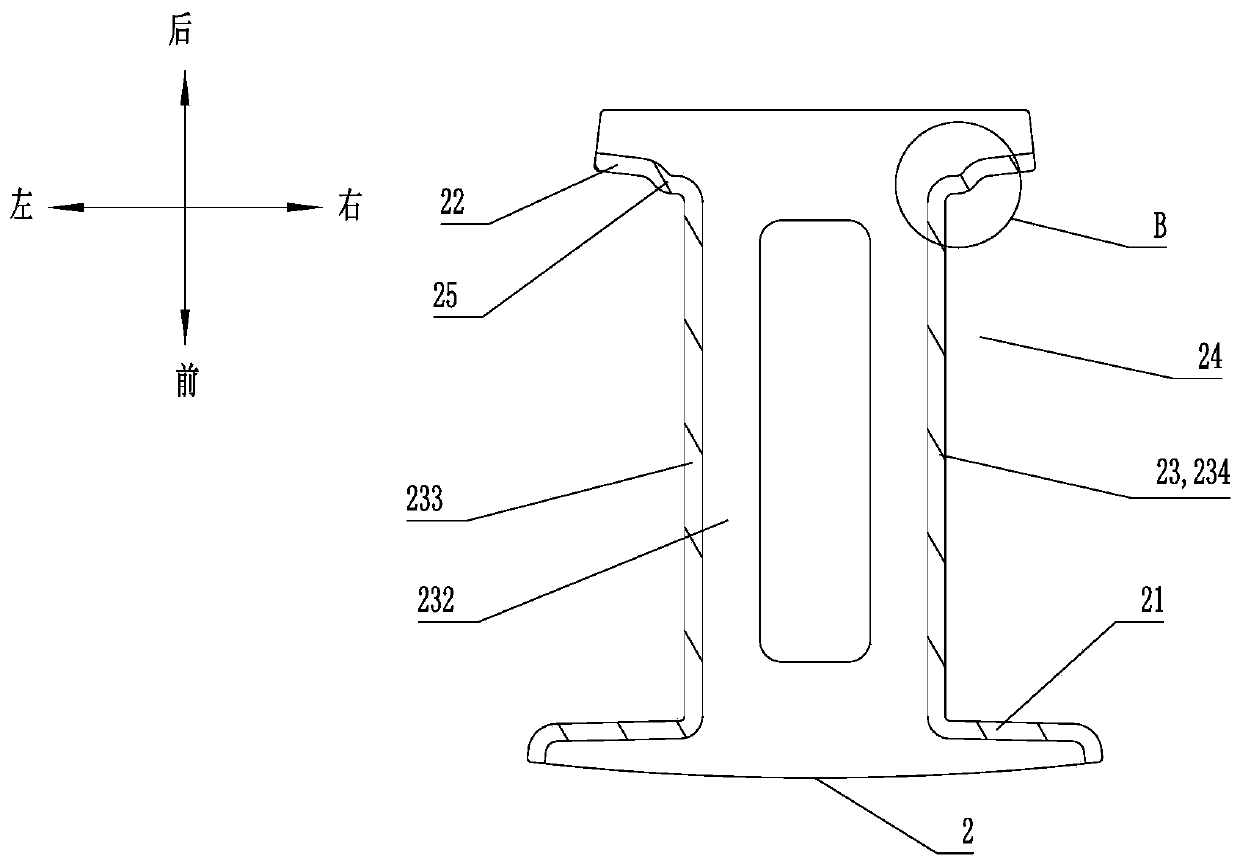

[0054] like Figure 1 to Figure 5 As shown, this embodiment discloses a stator tooth module, including a stator tooth 1, an insulating frame 2 and a winding 3, and the insulating frame 2 is sleeved on the stator tooth 1. In this embodiment, the insulating frame 2 is composed of an upper frame 2a and a The lower frame 2b is spliced together, and the insulating frame 2 adopts a two-half split structure, which not only facilitates the manufacture of the insulating frame 2, thereby reducing the manufacturing cost of the insulating frame 2, but also greatly facilitates the assembly of the insulating frame 2 to the Stator tooth 1, thereby facilitating the manufacture of the stator tooth module and improving production efficiency. The two-half split structure of the insulating frame 2 is an existing conventional technology, so it will not be repeated here.

[0055] The insulating frame 2 is provided with a front fender 21, a rear fender 22, and a support sleeve 23 between the front...

Embodiment 2

[0066] like Figure 1 to Figure 6 As shown, this embodiment discloses a stator, including the stator yoke 4 and the stator tooth modules in Embodiment 1, all the stator tooth modules are evenly distributed on the outer periphery of the stator yoke 4 in the circumferential direction, and each stator tooth module The stator tooth 1 and the stator yoke 4 are detachably spliced together. The detachable splicing structure of the stator tooth 1 and the stator yoke 4 is an existing conventional technology, so it will not be repeated here.

[0067] The stator in this embodiment is applied to a motor with an inner stator and an outer rotor structure. When the stator needs to be applied to a motor with an outer stator and an inner rotor structure, it is only necessary to distribute all the stator tooth modules evenly in the circumferential direction. The inner peripheral portion of the stator yoke 4 and each stator tooth module can be detachably spliced together with the stator yoke...

Embodiment 3

[0069] like Figure 1 to Figure 6 As shown, this embodiment discloses a motor, including the stator in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com