Preparation method and application of flexible all-solid-state super-capacitor based on two-dimensional pleated metal porphyrin framework ultra-thin nano-sheets

A technology of supercapacitors and metalloporphyrins, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, can solve problems such as hindering the efficient transmission of electrolyte ions, low conductivity of MPFs, and limited capacitive performance, and achieve excellent electrochemical performance. The effect of energy storage performance, simple operation, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of two-dimensional Cu-TCPP ultrathin nanosheets

[0043] (1) Copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) (1.8mg, 0.0075mmol), 4,4'-bipyridine (BPY) (0.78mg, 0.005mmol), 10.0mg polyvinylpyrrolidone (PVP) dissolved in 6mL N,N-dimethylformamide (DMF ) and ethanol (V:V=3:1) in a mixture;

[0044] (2)H 6TCPP (2.0mg, 0.0025mmol) was dissolved in a mixture of 2mL DMF and ethanol (V:V=3:1);

[0045] (3) Add (2) dropwise to (1), ultrasonicate (power 240W, frequency 40kHz) for 10min, transfer to blast drying oven, and react at 80°C for 3h;

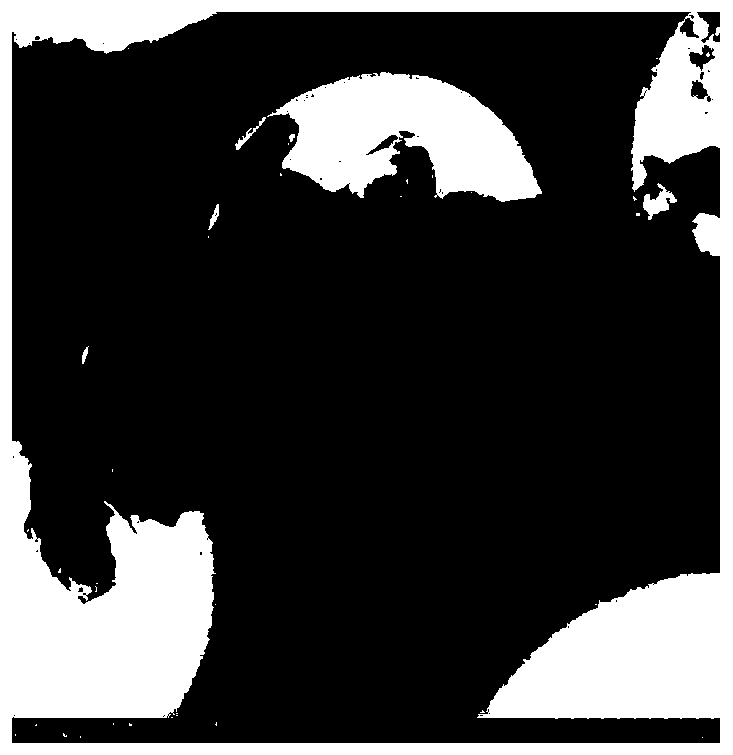

[0046] (4) After the reaction is finished, after cooling to room temperature to remove the supernatant, the resulting product is washed with ethanol and centrifuged (12000rpm, 10min) for 3 times. The TEM photo of the two-dimensional wrinkled Cu-TCPP ultrathin nanosheet is as follows: figure 1 shown.

Embodiment 2

[0047] Embodiment 2: the preparation of Cu-TCPP film

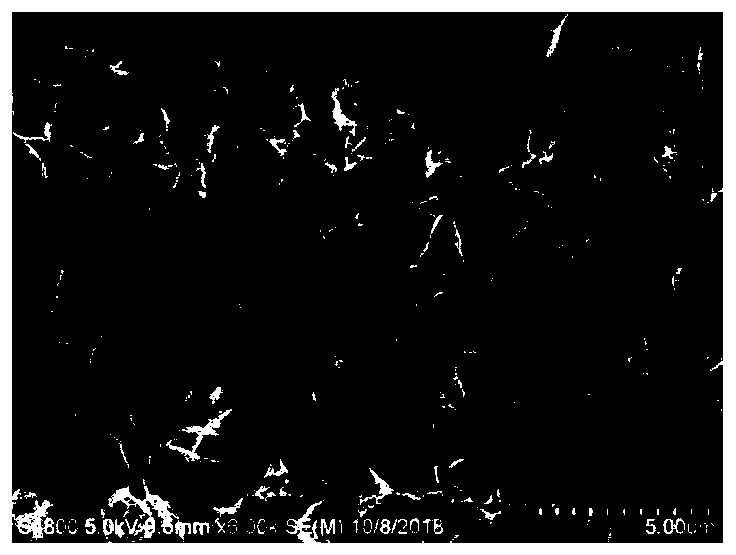

[0048] The two-dimensional 5.0mg Cu-TCPP ultrathin nanosheets were dispersed in the solution containing 3mg iodine (I 2 ) in 10mL of acetone, at 30V, energized for 30s, to obtain the Cu-TCPP film, the SEM photo of the two-dimensional wrinkled Cu-TCPP ultrathin nanosheet film, as figure 2 shown.

Embodiment 3

[0049] Embodiment 3: the preparation of PPy film

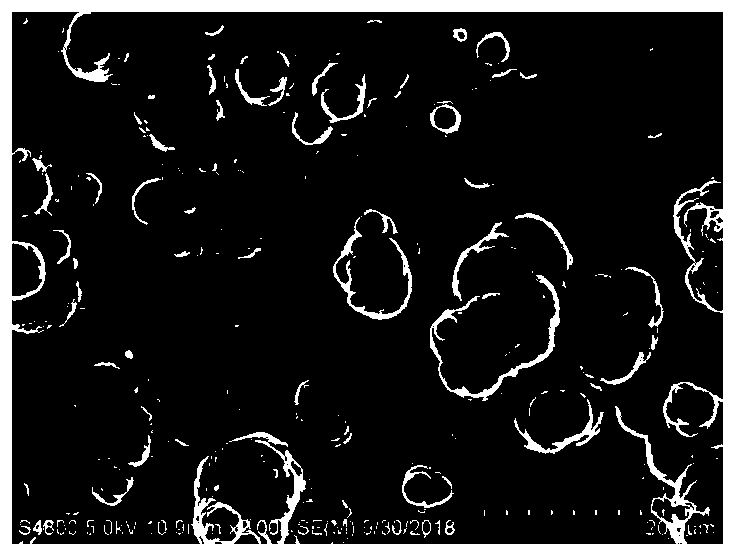

[0050] Solution preparation: Add 3.495g sodium p-toluenesulfonate, 1.141g p-toluenesulfonic acid, 600μL pyrrole into 60mL deionized water, let stand for 10h, stir magnetically for 10min, use Ag / AgCl electrode as reference electrode, Pt sheet as For the counter electrode, a blank ITO glass is used as the working electrode, and the constant voltage is 0.8V, and electrochemical polymerization is carried out, and the energization time is 600s to prepare the PPy film. Front SEM photographs of PPy films, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com