Production device for power cables resistant to alternating working conditions

A technology for power cables and production devices, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of talc powder affecting the quality of the next process, difficulty in processing, and difficulty in ensuring uniform thickness of the lubricating layer, so as to improve trouble-free The effect of working time, reducing heat generation, and increasing electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

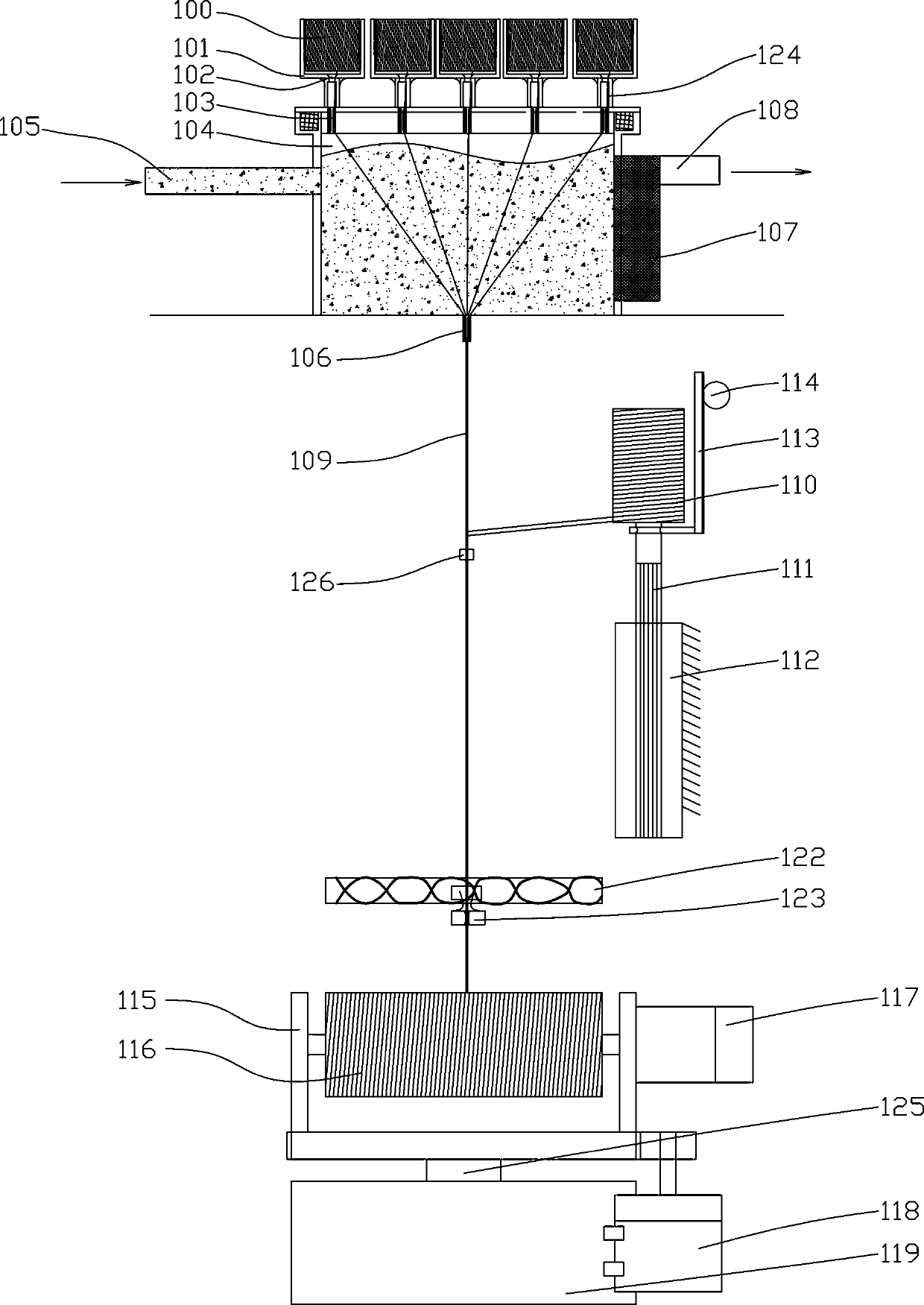

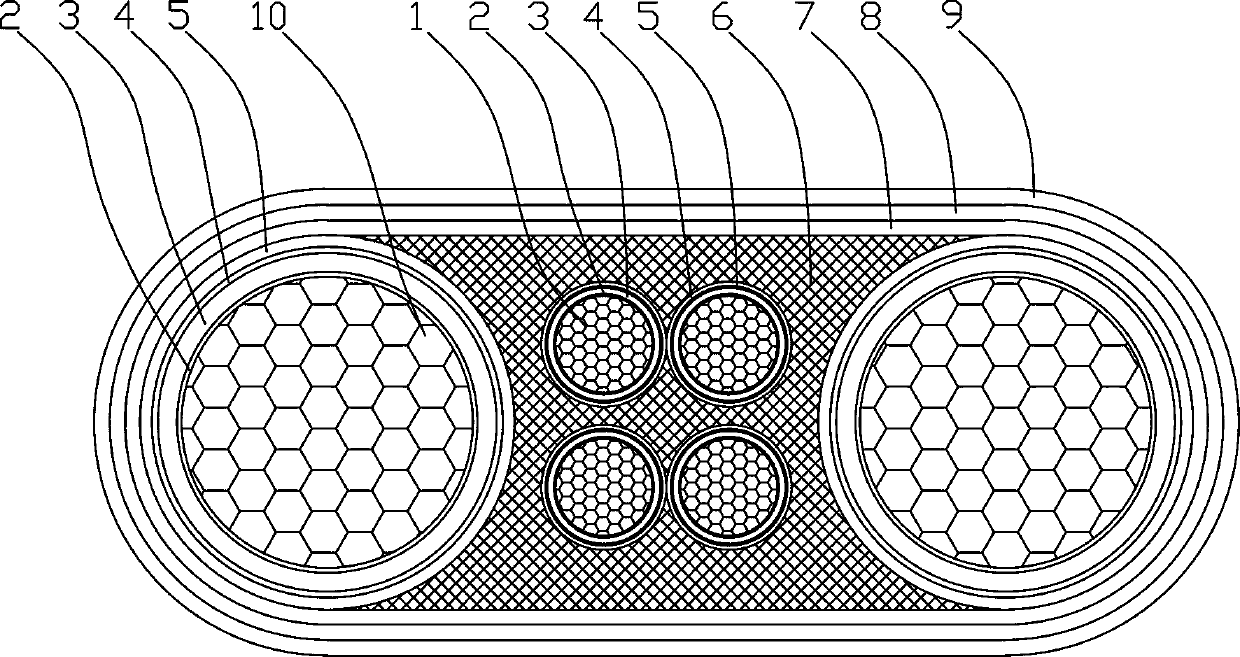

[0025] Such as image 3 Among them, the structure of the cable prepared by the device of the present invention is as follows: it includes a plurality of control cores 1 and power cores 10, and the control cores 1 are sequentially provided with insulating layers 3 and shielding layers; the power cores 10 are sequentially provided with Insulation layer 3 and shielding layer; rubber filling layer 6 is filled between each control wire core 1, between power wire cores 10 and between control wire core 1 and power wire core 10;

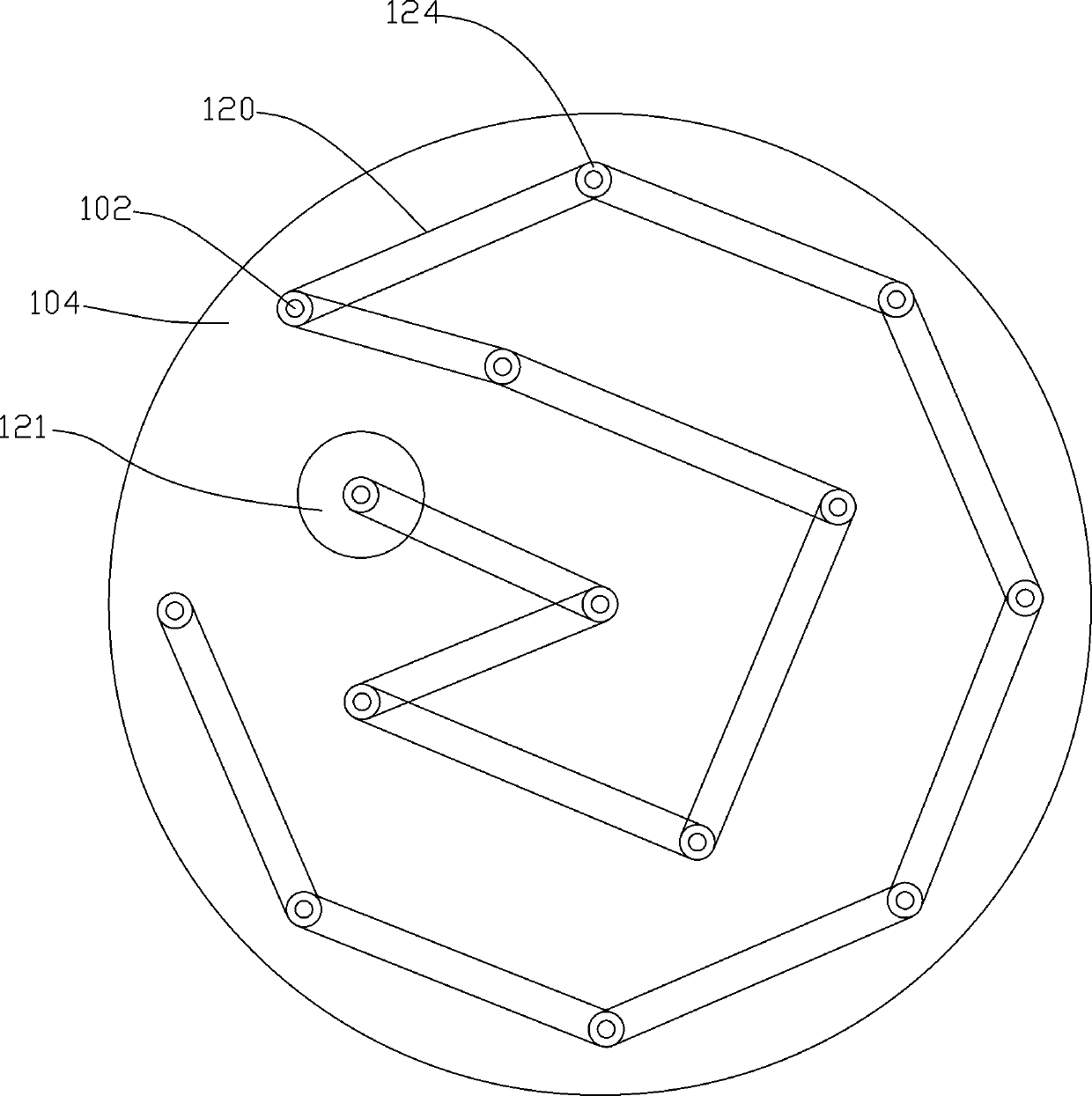

[0026] The cable assembly composed of the control wire core 1 and the power wire core 10 is provided with a fireproof belt 7 , a fiber braiding layer 8 and an outer sheath 9 in sequence. The number of control wire cores 1 is 2-8, and the number of power wire cores 10 is 2, 3 or 4; the control wire core 1 is located in the middle, and the power wire cores 10 are located around. The control wire cores 1 are arranged in pairs and twisted, and each control wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com