Wet planed sheet conveying device with flame retardant spraying device and flame retardant spraying method

A technology of conveying device and spraying device, which is applied in the direction of wood impregnation, wood processing equipment, impregnated wood, etc., can solve the problems that the flame retardant performance cannot meet the safety, the process complexity is high, and the cost is high, so as to achieve low cost, Improving the flame retardant effect and improving the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

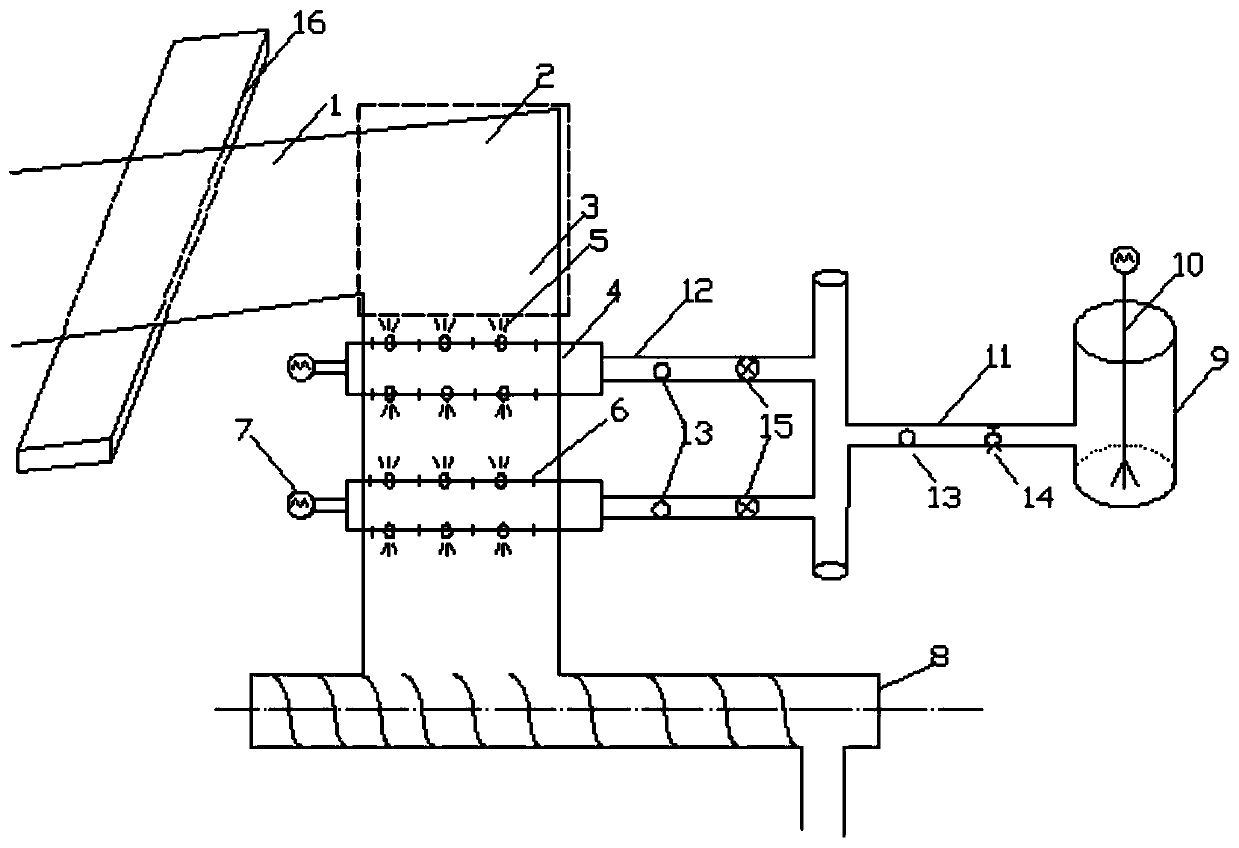

[0057] A wet flaking conveying device equipped with a flame retardant spraying device, the wet flaking conveying device includes: a belt 1, a blanking channel 3, a hollow drum 4, a screw extruder 8 and a spraying device;

[0058] The blanking channel 3 is connected with the belt 1, and the hollow drum 4 is arranged inside the blanking channel 3;

[0059] The screw extruder 8 is arranged below the blanking channel 3;

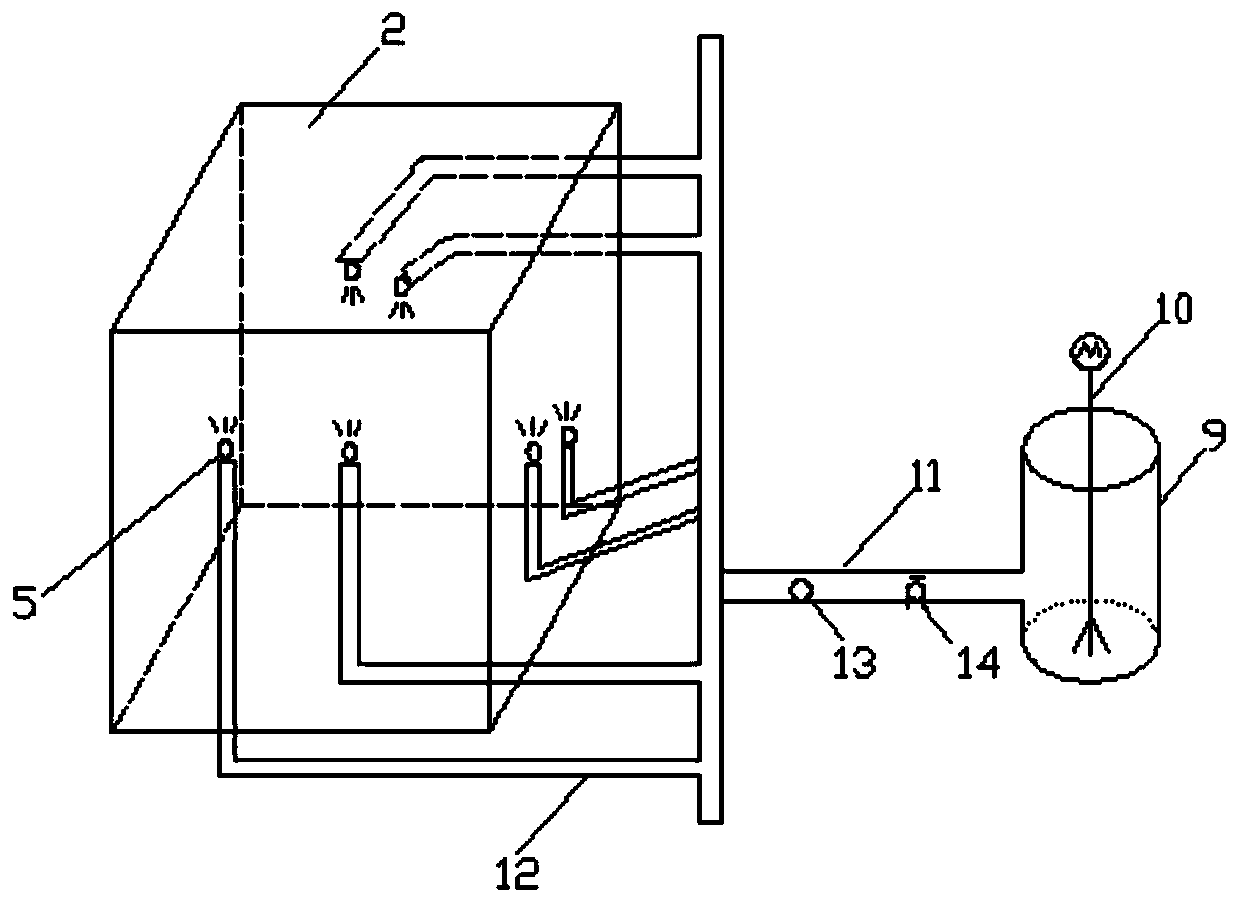

[0060] The spraying device is connected with the blanking channel 3; the spraying device includes: a flame retardant storage tank 9, a pressure nozzle 5 and a flame retardant delivery pipeline, and the pressure nozzle 5 is connected to the flame retardant storage tank 9 through the flame retardant delivery pipeline.

[0061] Such as figure 1 As shown, the pressure nozzles 5 are evenly arranged on the outer surface of the hollow cylinder 4, and 10 nozzles are arranged on each hollow cylinder. The installation angle of the pressure spray head 5 is perpendicular t...

Embodiment 2-19

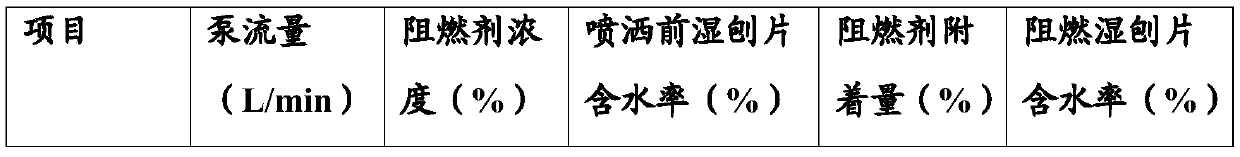

[0072] Adopt the device that embodiment 1 provides, wet shaving (wet shaving specification: width 5-40mm, thickness 0.4-0.8mm, length 100-180mm) enters in the blanking channel, from the top of the blanking opening of the blanking channel and around The flame retardant solution is sprayed towards the moving wet flakes; at the same time, in the blanking channel, the flame retardant solution is sprayed on the wet flakes while breaking up the wet flakes to obtain flame retardant flakes. The spraying range of flame retardant solution spraying can cover all slices.

[0073] The disintegration speed in Examples 1-14 is 20-30r / min, and the disintegration speed in Examples 15-19 is 40-50r / min.

[0074] The feeding capacity of the feeding port (in terms of dry flakes) is 10t / h.

[0075] The temperature of the flame retardant solution is 35±5°C;

[0076] The concentration of flame retardant in the flame retardant solution, the amount of flame retardant attached, the amount of flame ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com