In-burrow mounting tool for inner wear-proof casing of main driver of hard rock tunneling machine

A technology of hard rock boring machine and wear-resistant sleeve, which is applied in the direction of manufacturing tools and hand-held tools, etc., which can solve the problems of high transportation cost and delay of project cycle, reduce positioning restrictions, improve assembly quality, and facilitate construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

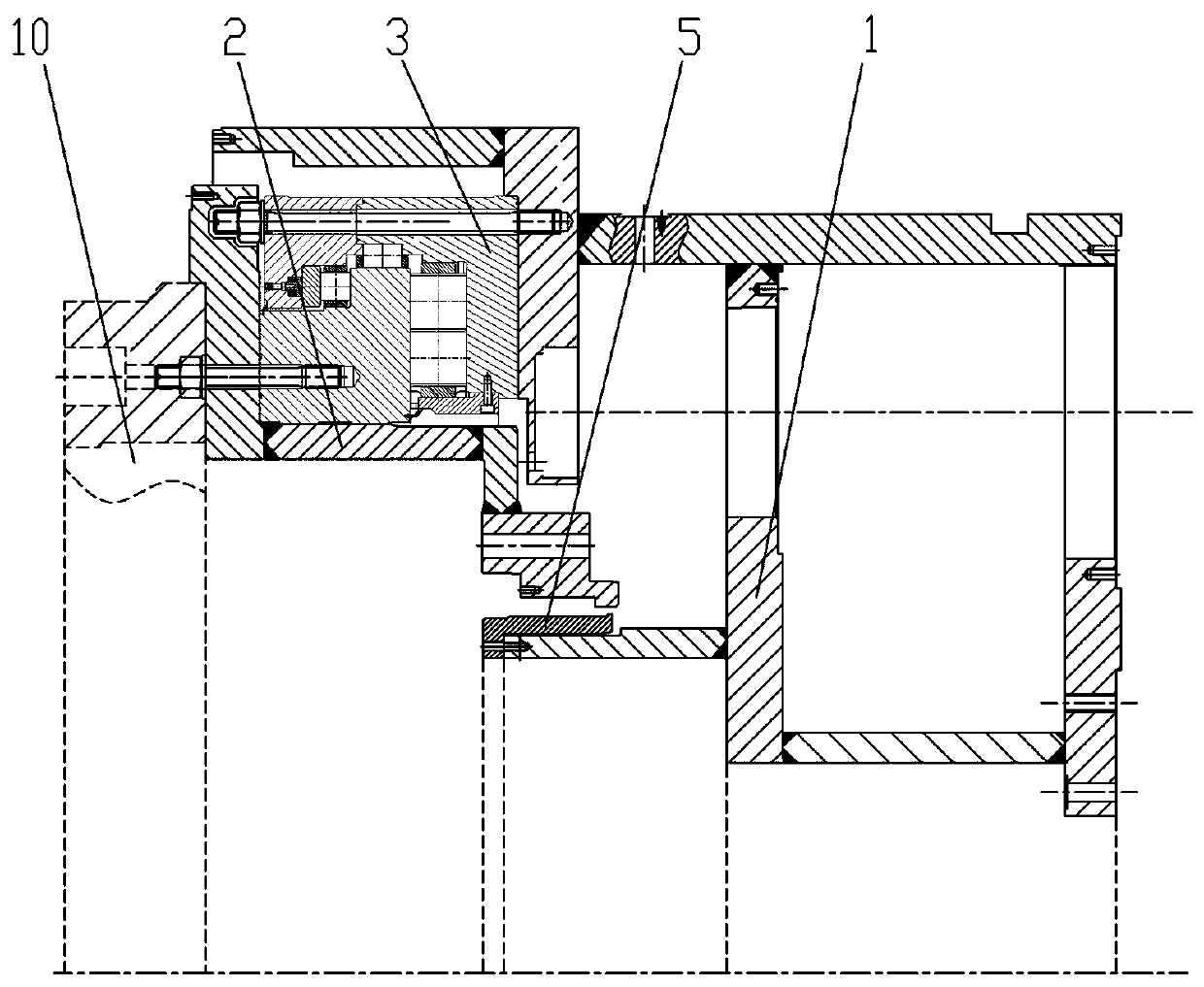

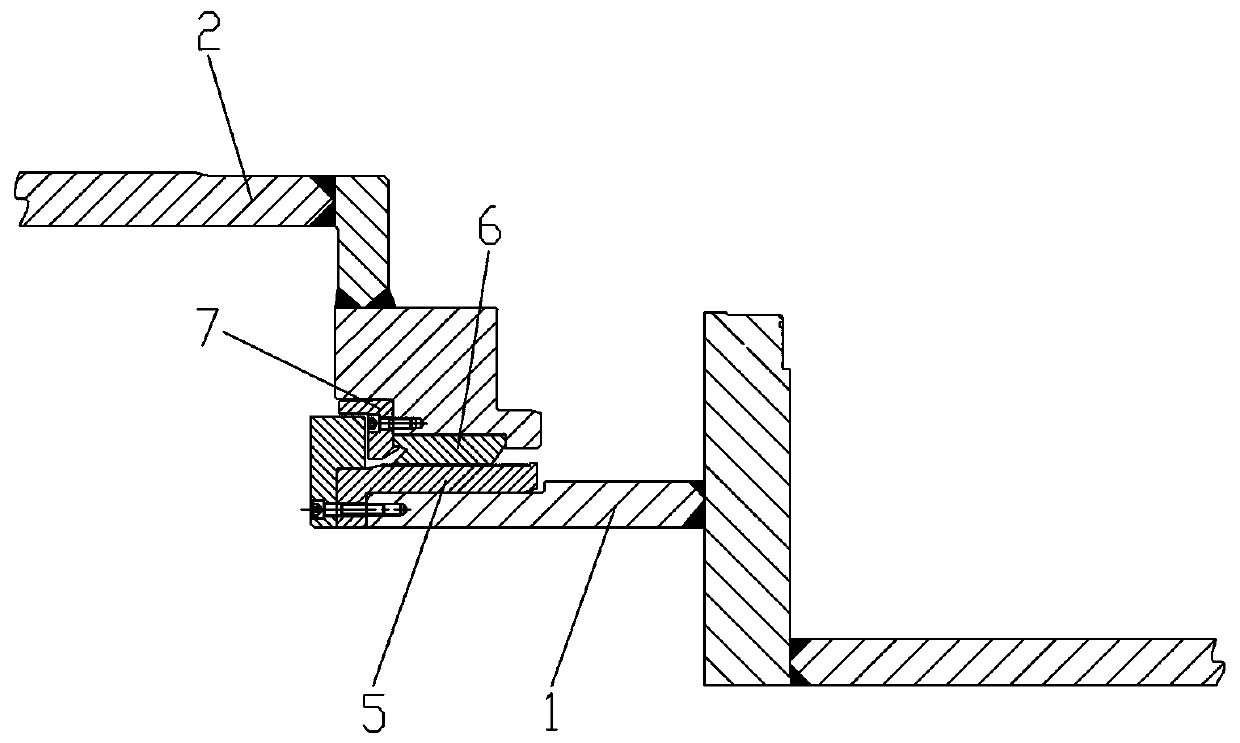

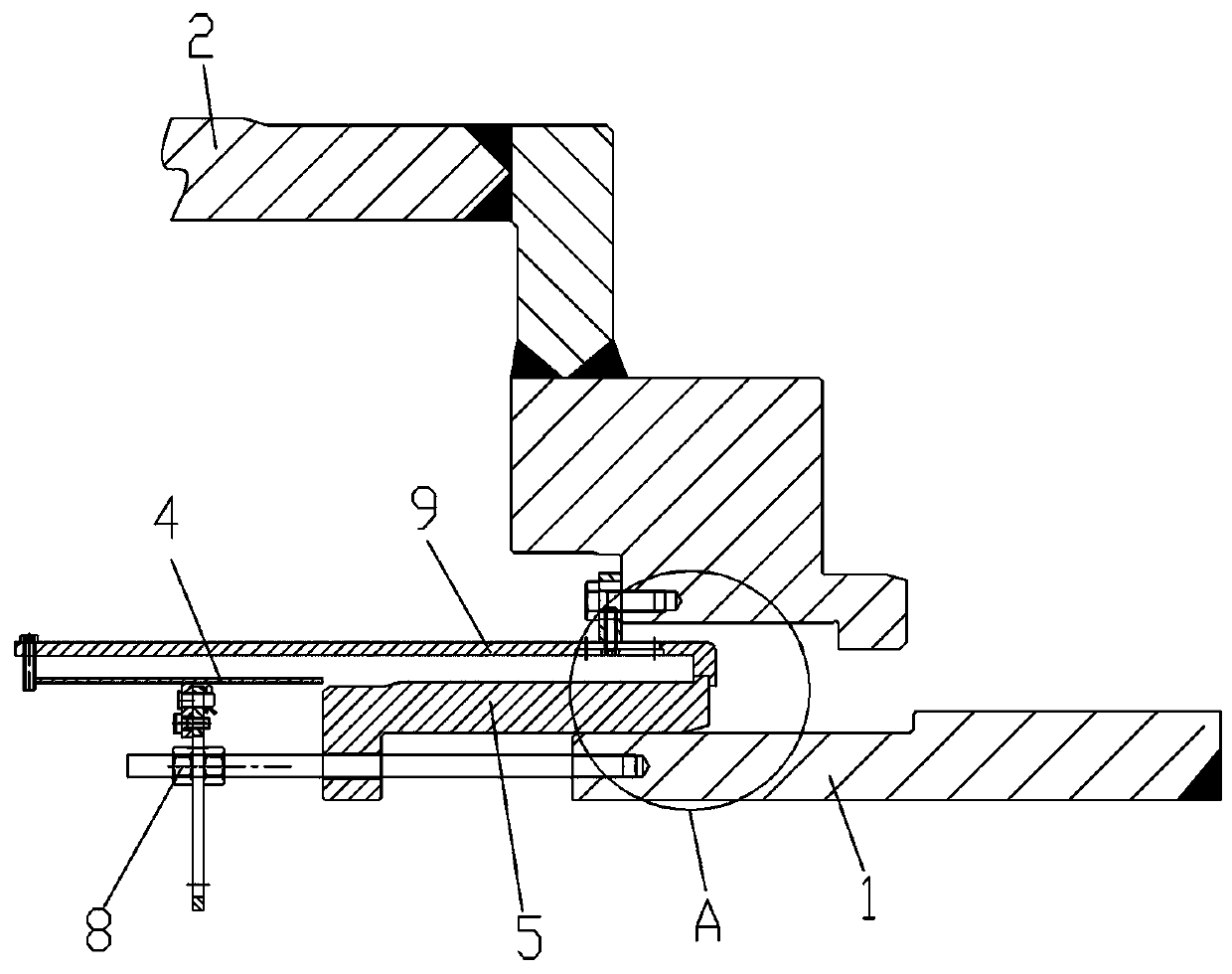

[0033] The hard rock roadheader main drive inner wear-resistant sleeve hole installation tool of the present invention includes a support tool 8 and a limit tool 9, and the support tool 8 passes through the fixing hole of the inner wear-resistant sleeve support ring 5 during use and is detachable It is arranged in the bolt hole of the fixed inner wear-resistant sleeve support ring 5 on one side of the upper part of the fixed support 1 of the main drive, and supports the inner wear-resistant sleeve 4; the limit tooling 9 is detachably arranged on the main drive In the bolt holes of the fixed lip-shaped sealing pressure ring 7 around the driven movable support 2, the inner wear-resistant sleeve 4 plays a position-limiting role during installation.

[0034] The support tooling 8 includes a support frame plate 801, a fixed seat plate 802, a support screw rod 803, a positioning bolt 804 and a lock nut 805. The fixed seat plate 802 is provided with a waist-shaped hole 821, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com