Low-pressure shunting device

A shunt device, low-pressure technology, applied in the field of low-pressure shunt device, shunt device of aluminum alloy low-pressure casting process, can solve the problems of shunt device sticking to aluminum, long disassembly time, blockage, etc., to improve versatility and interchangeability , Reduce processing difficulty, reduce the effect of using cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

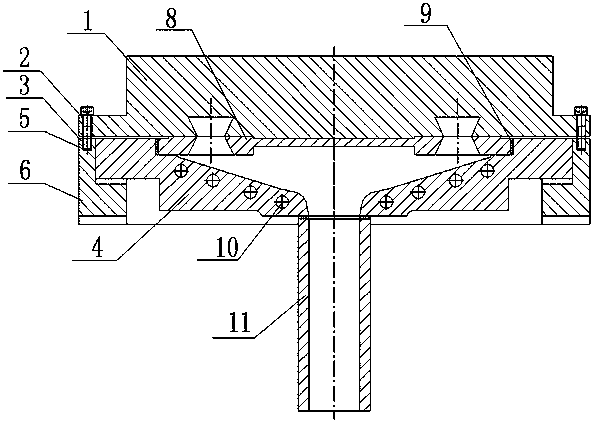

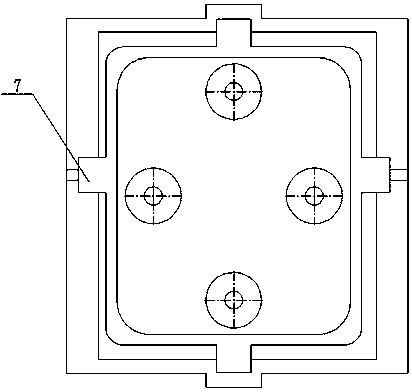

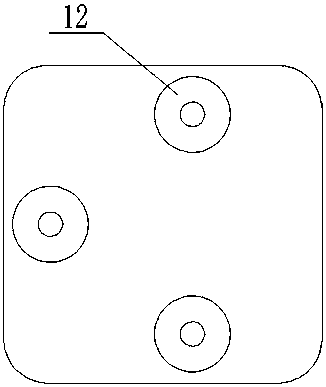

[0019] figure 1 , 2 , 3, 4, the present invention includes connection frame 6, diversion basin 4, diversion cover 8, bolt 3, asbestos pad 9, heating pipe 10 and so on. The connecting frame 6 is provided with positioning grooves 7 matched with the distribution basin 4 on the periphery. There are three upper cylindrical bosses 12 on the outer wall of the diverter cover 8, and three lower cylindrical bosses 13 in the inner cavity. A heating pipe hole 10 is arranged on the distribution basin 4 . A positioning space for positioning with the mold body is formed between the three upper cylindrical bosses 12 .

[0020] When installing, first put the asbestos pad 9 into the inner wall of the distribution basin 4, and then press the distribution cover 8 into the groove of the distribution basin 4. The height of the upper cylindrical boss 12 of the distribution cover 8 after assembly is higher than that of the distribution basin. 4 on the plane. After installing, put the protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com