Automatic vertical direction film coating machine

A vertical direction, film coating machine technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of uneven thickness of the surface film of the needle sensor electrode, the influence of the detection accuracy of the sensor electrode, etc., to increase flexibility and convenience, increased stability, reduced jitter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

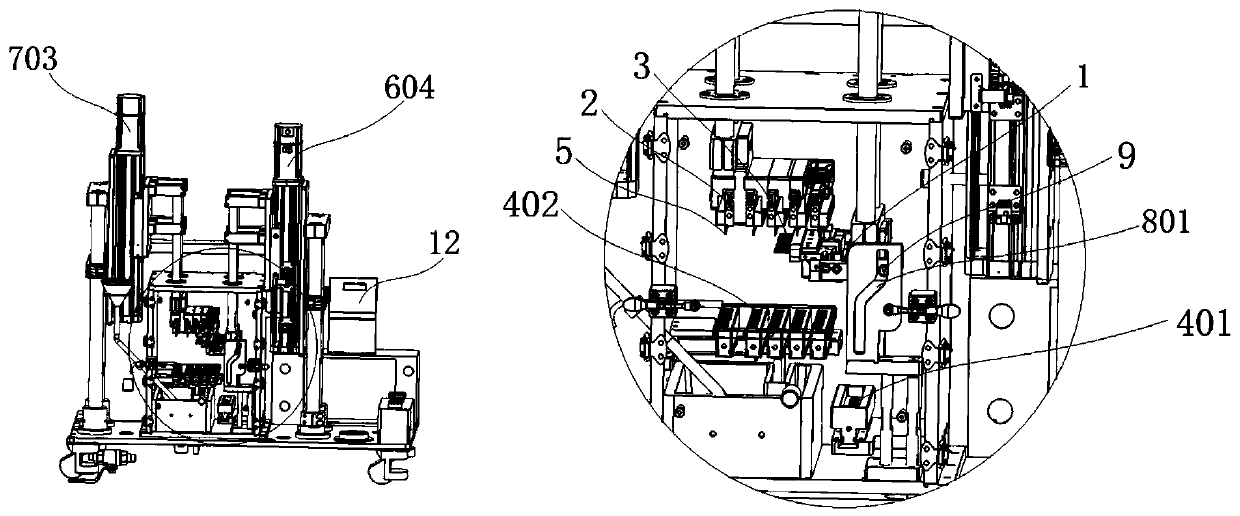

[0051] coating machine, such as figure 1 As shown, it includes a support 1 for installing the coating ring, a clamp 2 for clamping the sensor electrode to be coated, a coating ring 3, and a first vertical movement for moving the support 1 in the vertical direction mechanism, a steering mechanism for turning the support 1 and a second vertical movement mechanism for moving the clamp 2 in the vertical direction. The shape of the coating ring, for example, can be as Figure 8 shown. The film coating machine also includes a first membrane liquid tank 401 for immersing the film coating ring 3 and a second film liquid tank 402 for immersing the sensor electrode to be coated. When the support 1 is in a horizontal state, the plane where the coating circle 3 is located is located in the horizontal plane, and the coating circle 3 is aligned with the sensor electrode 5 to be coated; when the support 1 is in a vertical state, the plane where the coating circle 3 is located It is locate...

Embodiment 2

[0073] In this embodiment, except that the steering mechanism is designed so that the support can automatically turn under the cooperation of the steering mechanism and the vertical movement mechanism, the rest of the structure can be the same as that of Embodiment 1. The vertical motion mechanism described in this embodiment corresponds to the first vertical motion mechanism in Embodiment 1.

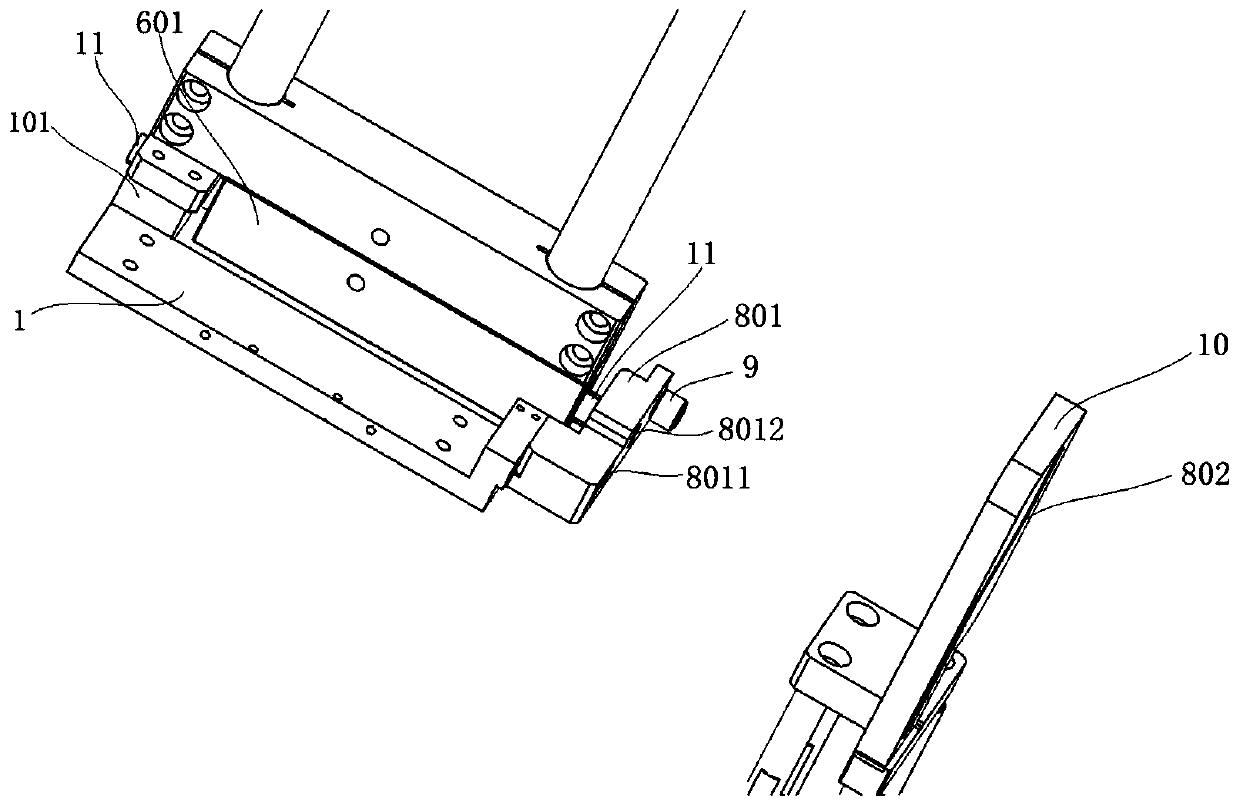

[0074] Vertical automatic film coating machine, such as figure 1 As shown, it includes the coating circle, the support 1 for installing the coating circle, the vertical movement mechanism for moving the support in the vertical direction and the steering mechanism for turning the support. The vertical movement mechanism includes The fixed block 601 and the driving device for driving the fixed block 601 to move vertically. Such as figure 2 with image 3As shown, the steering mechanism includes a connecting block 801 for connecting the support 1 and the fixed block 601 and a track 802 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com