Cylinder liner and piston ring friction wear test device

A friction and wear test, piston ring technology, applied in the direction of testing wear resistance, etc., can solve the problems of less measurable variables, the tribological performance of piston ring and cylinder liner materials, the deterioration of lubricating oil lubrication quality, and the reduction of service life, etc., to achieve convenience and speed The adjustment and fixing methods are convenient and reliable, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

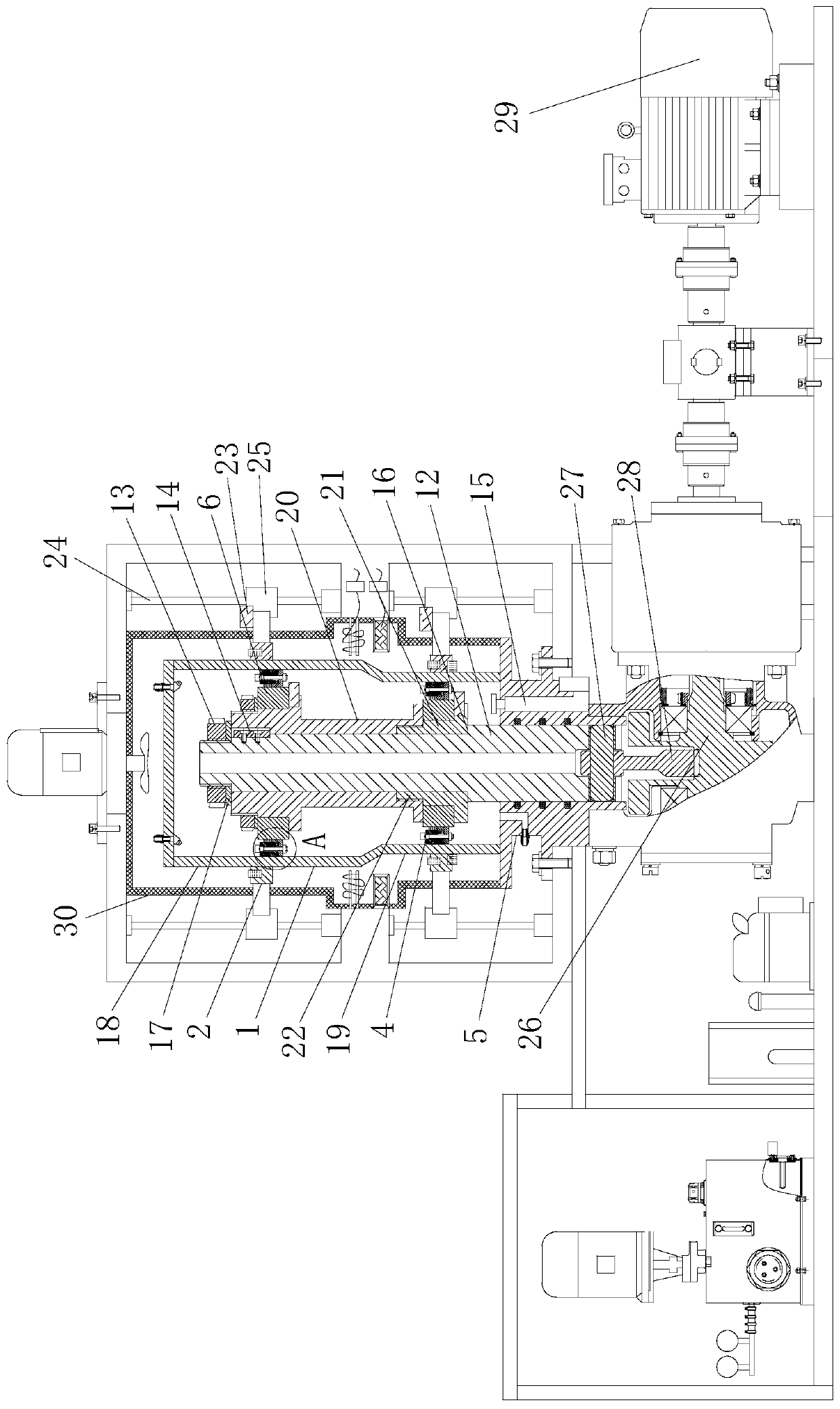

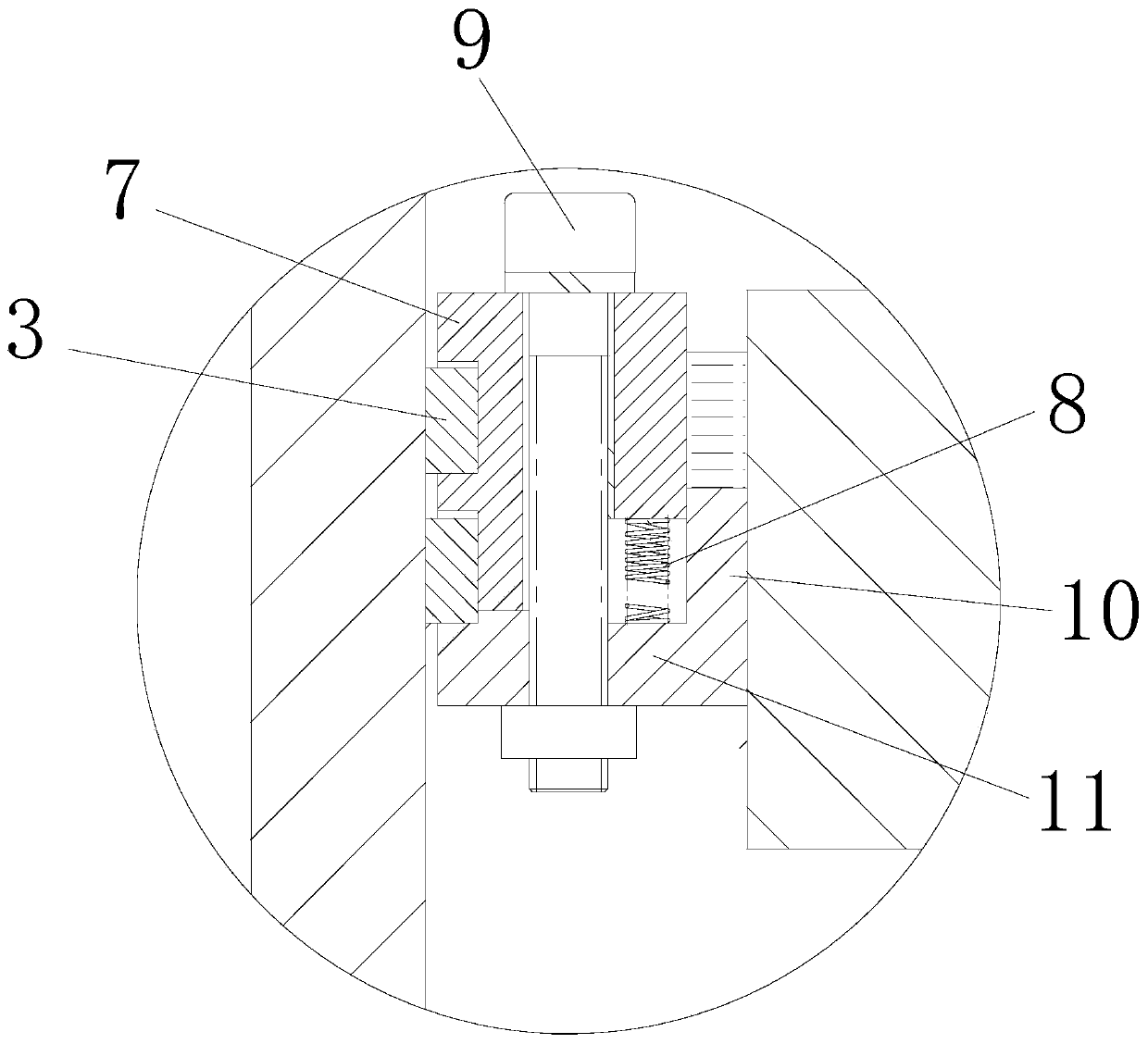

[0031] A cylinder liner-piston ring friction and wear test device, comprising: piston rod, cylinder liner 1, cylinder clamping mechanism 2, lifting mechanism, crankshaft, piston ring 3, plug ring clamping mechanism 4, guide seat 5 and inner radial The adjustment mechanism 6, the piston rod extends into the cylinder liner 1, the inner radial adjustment mechanism 6 is fixed on the piston rod, the plug ring clamping mechanism 4 is set on the inner radial adjustment mechanism 6, and the piston ring 3 is installed on the plug ring clamping mechanism 4, the piston ring 3 is in contact with the inner wall of the cylinder liner 1; the cylinder liner 1 is fixed on the cylinder body clamping mechanism 2, and the cylinder body clamping mechanism 2 is connected with the lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com