Isolation and shielding device and method for valve internal leakage

A shielding device and valve technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as escape, valve life reduction, combustion, etc., to achieve high judgment accuracy, good shielding effect, and investment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

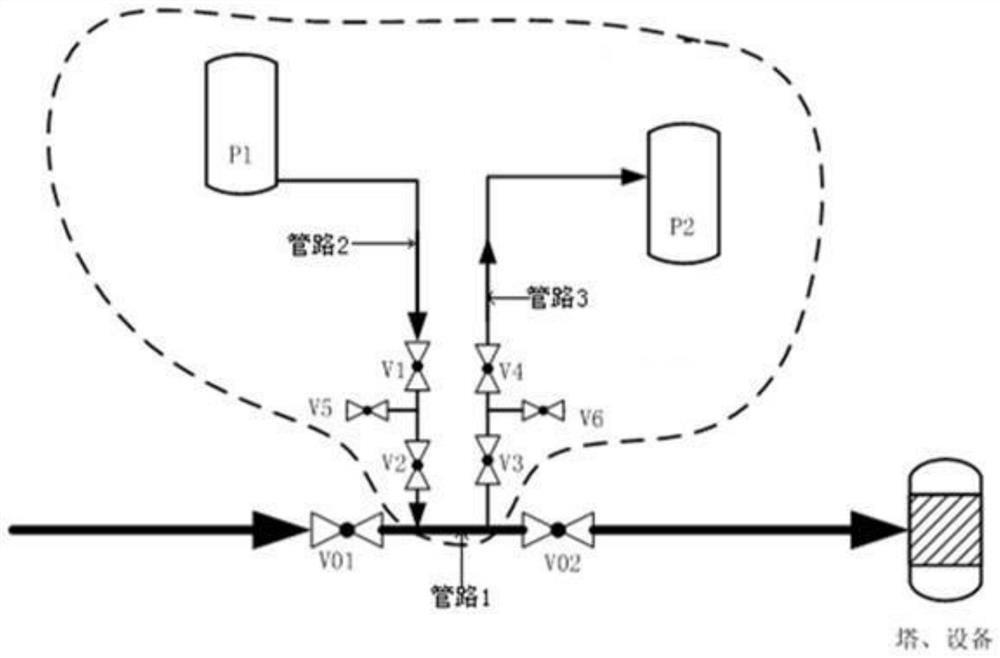

[0027] combine figure 1 The isolation process device and flowchart shown in the figure, valve 1 is VO1, valve 2 is VO2, valve 3 is V1, valve 4 is V2, valve 5 is V5, valve 6 is V3, valve 7 is V4, valve 8 is V6, gas tank 1 is P1, and gas tank 2 is P2.

[0028] Its device is:

[0029] The pipeline between the adjacent valve 1 (VO1) and valve 2 (VO2) that communicates with the equipment is pipeline 1, and pipeline 1 communicates with gas tank 1 (P1) through pipeline 2, and connects with gas tank 1 (P1) through pipeline 3. The gas tank 2 ( P2 ) is in communication; and the junction of pipeline 2 and pipeline 1 is located between the junction of pipeline 3 and pipeline 1 and valve 1 .

[0030] The gas tank 1 (P1) is an inert gas tank; the pressure of the gas in the gas tank 1 is greater than the pressure of the gas in the gas tank 2 .

[0031] The pipeline 2 is provided with a side leakage valve group 1, and the side leakage valve group 1 includes: valve 3 (V1), valve 4 (V2) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com